Nothing damages brand credibility faster than receiving a bulk order where the "navy blue" masks vary across five different shades. Color inconsistency creates customer complaints, rejected shipments, and costly remakes that can erase your profit margin. Achieving perfect color consistency across large productions requires systematic approaches beyond simple quality checks.

Ensuring consistent dye color across 10,000+ fabric mask orders requires standardized dyeing procedures, digital color management technology, batch control systems, and rigorous supplier qualification. Success depends on controlling every variable from raw material consistency to final production under standardized lighting conditions.

Color consistency isn't a single step but a comprehensive system spanning from initial lab dip approval through bulk production and final inspection. Understanding this process helps brands maintain their color integrity across large orders and multiple production runs.

What Pre-Production Processes Prevent Color Variation?

The foundation of color consistency is established long before bulk dyeing begins, through meticulous preparation and standardization.

Why are lab dips and digital standards crucial?

Lab dips serve as the physical color reference that bridges your digital design and mass production. Each lab dip undergoes spectrophotometer measurement to establish a digital color standard with precise Delta E tolerance levels (typically ≤2.0 for acceptable matches). This process includes testing under multiple light sources to identify metamerism—when colors appear different under various lighting conditions. We require clients to approve lab dips against their standards under D65 daylight simulation to ensure the match holds in real-world conditions.

How does fabric standardization impact color results?

Even with perfect dye formulas, variations in raw fabric composition, weave density, and absorbency create color differences. Establishing fabric quality specifications for weight, thread count, and composition ensures consistent dye absorption across production runs. Our approach includes pre-testing fabric lots for pH levels and residual chemicals that might affect dye uptake, rejecting materials that fall outside established parameters before they enter production.

What Production Controls Maintain Color Consistency?

During bulk dyeing, multiple technical and procedural controls prevent the gradual color drift that plagues large productions.

How do standardized dyeing procedures work?

Consistent color requires repeatable dyeing processes with controlled variables including water quality, dye concentration, temperature curves, and processing times. Professional dye houses maintain detailed standard operating procedures (SOPs) for each color and fabric combination, with computerized systems controlling critical parameters. Our partner dye facilities use automated dye dispensing that weighs pigments to 0.01-gram accuracy, eliminating human measurement error that causes batch-to-batch variation.

What is lot tracking and why does it matter?

Each dye lot receives a unique identifier that tracks it through every production stage. This batch control system ensures that masks cut from the same fabric roll maintain perfect color matching, while adjacent lots are verified for consistency before proceeding to cutting. For 10,000-piece orders, we typically maintain 3-5 dye lots maximum, with each lot containing sufficient fabric for 2,000-3,500 masks to minimize transitions. This systematic approach prevents the color banding that occurs when numerous small lots are combined.

How Does Technology Enable Color Consistency?

Modern color management relies on sophisticated technology that removes subjectivity and provides objective measurement throughout production.

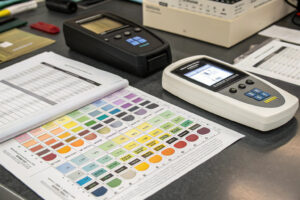

What role do spectrophotometers play?

Spectrophotometers provide objective color measurement by quantifying color as numerical values across the visible spectrum. These devices measure colors under standardized lighting conditions, detecting variations invisible to the human eye. We position spectrophotometers at four critical control points: raw fabric inspection, after dyeing, after finishing, and during final inspection. This multi-stage verification catches color drift early, when corrections are still possible without scrapping entire production runs.

How do digital color systems maintain standards?

Digital color management systems create a centralized color library containing all approved standards, formulas, and tolerance ranges. These systems automatically flag deviations and generate correction formulas when colors drift outside established parameters. Our digital color workflow has reduced color-related rejections by 78% compared to traditional visual assessment methods, while cutting color correction time from days to hours through automated recalculation of dye formulas.

What Post-Dyeing Factors Affect Color Consistency?

The color journey doesn't end when fabrics leave the dye bath—multiple subsequent processes can alter appearance if not properly controlled.

How do finishing processes impact final color?

Processes like softening, water repellency treatment, and antimicrobial finishing can significantly alter color appearance. Each finishing chemical must be tested for color impact before approval for production use. We maintain a database of finishing agents and their effects on different color families, allowing us to predict and compensate for color shifts during formula development. This proactive approach prevents surprises after substantial investment in dyeing and finishing.

Why does lighting standardization matter in inspection?

The same color can appear dramatically different under various light sources, making standardized lighting conditions essential for accurate inspection. Our quality control stations use D65 daylight simulation bulbs with consistent color temperature (6500K) and high color rendering index (CRI ≥90) to match the conditions used during lab dip approval. This eliminates the "store lighting surprise" where colors approved in the factory appear different in retail environments.

How Can You Verify Consistency Before Shipment?

Final verification processes ensure that color consistency meets your standards before products leave the factory.

What sampling methods detect color variation?

Statistical sampling using AQL (Acceptable Quality Level) standards provides a systematic approach to verifying color consistency across large orders. For color evaluation, we typically use AQL 1.0 (more stringent than standard 2.5) with samples drawn from each dye lot and production date. Inspectors compare samples against approved standards under controlled lighting, using spectrophotometers for objective measurement of any questionable pieces. This method provides 95% confidence in detecting color issues affecting more than 1% of the shipment.

How does documentation provide color assurance?

Complete color documentation packages include lab dip approvals, dye lot records, spectrophotometer reports, and inspection certificates. This documentation trail provides objective evidence of color consistency and helps resolve any disputes about color matching. For our clients, we provide digital access to color measurement data for every production lot, creating transparency and building confidence in our color management capabilities.

Conclusion

Ensuring consistent dye color across 10,000+ fabric mask orders requires a comprehensive system encompassing standardized procedures, advanced technology, rigorous process controls, and thorough verification. From initial lab dip development through final inspection, each step must be managed with scientific precision to maintain color integrity across large productions. The investment in proper color management pays dividends through reduced rejections, stronger brand consistency, and enhanced customer satisfaction.

Ready to achieve perfect color consistency in your large fabric mask orders? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our comprehensive color management system and how we maintain color integrity across productions of any size. We'll show you how scientific color control can protect your brand reputation and bottom line.