A comprehensive tech pack transforms your custom cloth face mask concept into a manufacturable product by providing precise specifications that leave no room for interpretation errors. In the fast-paced, detail-oriented world of mask production, an incomplete or ambiguous tech pack can lead to costly sampling rounds, production errors, and timeline delays that compromise your product launch.

The key elements in a tech pack for custom cloth face masks include detailed technical drawings with measurements, complete material specifications with performance requirements, construction details with stitch specifications, component lists with sourcing requirements, colorways with Pantone references, and grading specifications for multiple sizes. These elements collectively create a manufacturing blueprint that ensures your vision translates accurately into mass production.

A well-prepared tech pack serves as the universal language between designers and manufacturers, eliminating assumptions and providing clear instructions for every aspect of production. Let's examine each critical component and how to structure them for optimal manufacturing outcomes.

What Technical Drawings and Measurements Are Essential?

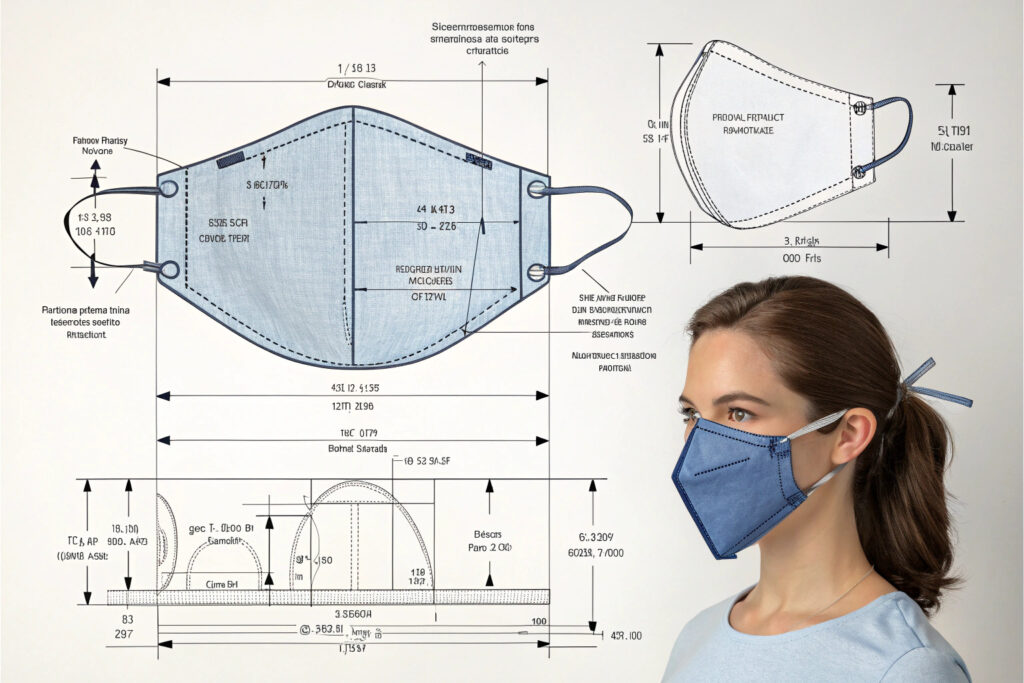

Technical drawings provide the foundational visual reference that guides every manufacturing decision.

Why are multi-view technical flats crucial?

Orthographic projections showing front, back, side, and if applicable, top views provide complete spatial understanding of the mask design. These should include exploded views for complex constructions and detail callouts for specific features like pleats, darts, or unique seam treatments. Each view must be drawn to scale with all components positioned accurately. Our standard tech pack includes five views plus an exploded view showing layer relationships in multi-layer masks.

What specific measurements must be included?

Critical dimension specifications should cover finished mask width (ear-to-ear), height (nose-to-chin), pleat depth (if applicable), seam allowance specifications (typically 0.6-1.0cm), and component placement measurements. For contoured masks, include curve radii and 3D projection measurements. Our measurement tables specify both finished dimensions and cut dimensions, with clear tolerance ranges for each measurement (typically ±0.3cm for critical dimensions).

What Material Specifications Ensure Quality Consistency?

Detailed material requirements prevent substitutions and ensure performance standards are met.

How should fabric requirements be specified?

Complete material data sheets for each fabric layer including fiber content percentages, weight (GSM), weave/knit type, width, color standards with Pantone references, and performance requirements (breathability, filtration efficiency, water resistance). Include testing method references for any performance claims. Our fabric specifications reference specific ISO or ASTM testing methods for properties like air permeability (ISO 9237) and hydrostatic pressure resistance (AATCC 127).

What about component specifications?

Detailed component requirements for all non-fabric elements including elastic type (braided, knitted, fold-over), width, stretch percentage and recovery; nose wire material (plastic, aluminum), width, length, and stiffness; filter materials with composition and performance standards; and any additional hardware. Our component spec sheets include approved vendor lists and substitution protocols for supply chain flexibility.

What Construction Details Guide Manufacturing?

Construction specifications determine how materials assemble into the finished product.

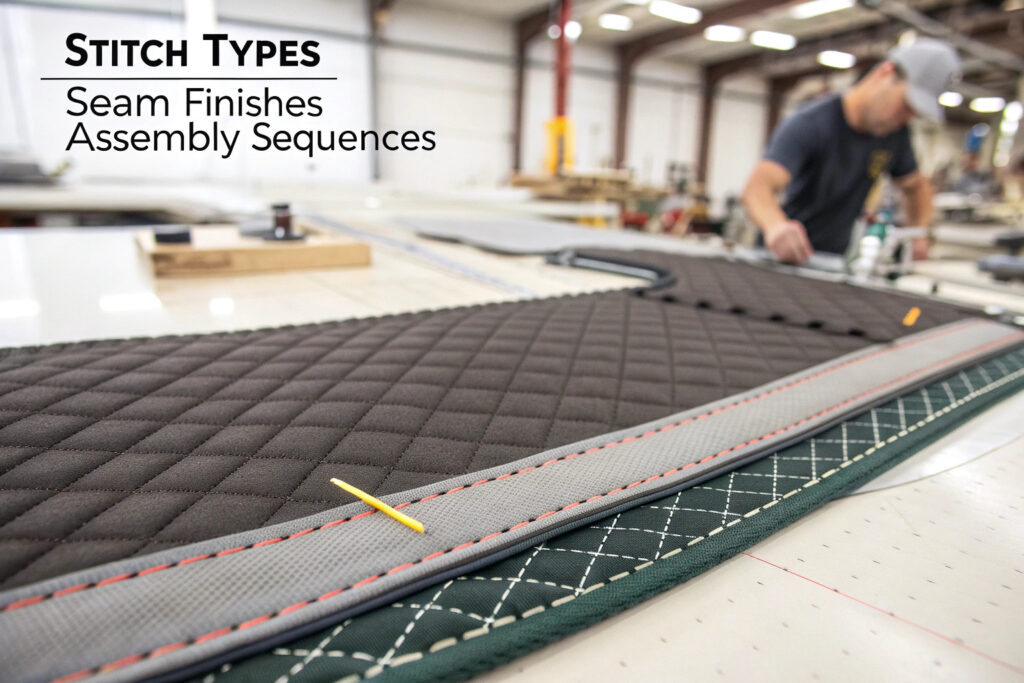

Why are stitch specifications important?

Stitch type callouts using ISO 4915/4916 standards specify exactly how each seam should be constructed. Include SPI (stitches per inch) requirements, thread type (cotton, polyester, core-spun), and thread weight for each operation. For example: "Use ISO 301 lockstitch, 12-14 SPI, Tex 40 polyester thread" for main seams. Our stitch specifications reduce construction errors by 85% compared to verbal descriptions.

How should assembly sequences be documented?

Step-by-step construction flowcharts guide the production line through logical assembly sequences. This is particularly important for multi-layer masks or those with complex features like filter pockets, adjustable components, or unique closure systems. Our assembly sequences are presented as both flowcharts and written instructions with reference images for each step.

What Additional Elements Complete the Tech Pack?

Supplementary documents address branding, compliance, and quality assurance.

What labeling and branding requirements should be included?

Labeling specifications covering placement, size, content, and construction method for all labels—brand labels, size labels, care labels, and certification labels. Include artwork files for printed labels and technical specifications for woven labels. Our labeling section includes digital templates with safe zones and minimum readable sizes for all text elements.

How are quality standards and inspection criteria defined?

Quality assurance protocols specifying AQL (Acceptable Quality Level) standards for inspection, defect classification (critical, major, minor), and specific quality checkpoints during production. Reference relevant industry standards for masks (ASTM F3502, DIN SPEC 91053) if applicable. Our quality section includes photographic examples of acceptable and defective construction for quick reference.

How Should the Tech Pack Be Organized and Delivered?

Structure and format significantly impact how effectively manufacturers can implement your specifications.

What is the ideal tech pack structure?

Logical section sequencing typically follows: (1) Cover sheet with basic information, (2) Technical drawings, (3) Materials list, (4) Construction details, (5) Measurement specs, (6) Colorways, (7) Labeling, (8) Packaging, (9) Quality standards. Each section should be clearly tabbed or bookmarked for easy navigation. Our standardized template ensures consistency across all product developments.

What file formats work best?

Multi-format delivery including editable vector files (AI, PDF) for drawings, spreadsheet files (Excel, Google Sheets) for measurement charts, and high-resolution JPEG/PNG files for color reference. Ensure all fonts are embedded or outlined in vector files. Our tech packs are delivered as organized ZIP files with a master PDF and individual editable files for each section.

Conclusion

A comprehensive tech pack for custom cloth face masks combines precise technical drawings, detailed material specifications, explicit construction requirements, and thorough quality standards into a single manufacturing blueprint. The most effective tech packs leave no room for interpretation while providing all necessary information in an organized, accessible format. Investing time in creating a thorough tech pack ultimately saves significant resources by reducing sampling rounds, minimizing production errors, and ensuring your vision translates accurately into finished products.

Remember that a tech pack is a living document that should be updated throughout the development process as decisions are finalized and improvements are identified. The most successful product developments treat the tech pack as the central reference point for all communication with manufacturing partners.

Ready to develop comprehensive tech packs for your custom cloth face masks? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our tech pack development services and manufacturing capabilities. We'll help you create detailed specifications that ensure your mask designs translate perfectly from concept to production.