The modern global supply chain is a complex, interconnected system vulnerable to disruptions ranging from geopolitical tensions and natural disasters to port congestions and supplier insolvencies. AI-powered supply chain risk prediction platforms have emerged as critical tools for businesses seeking to move from reactive crisis management to proactive risk mitigation. For procurement managers, supply chain directors, and business owners, especially those reliant on international sourcing like mask manufacturing, understanding how to access and implement these platforms is essential for building resilience and maintaining operational continuity.

AI-powered supply chain risk prediction platforms are advanced software solutions that utilize machine learning algorithms, natural language processing, and vast datasets to analyze internal and external factors, identify potential disruptions before they occur, quantify their impact, and provide actionable recommendations for mitigation. These platforms transform raw data—from weather patterns and news headlines to shipping schedules and supplier financials—into predictive intelligence. Accessing these platforms requires navigating a landscape of vendors, deployment models, and integration requirements tailored to business size and complexity.

The global market for supply chain risk management solutions is projected to reach $7.5 billion by 2029, with AI-driven platforms experiencing the fastest growth. According to research by Gartner, organizations using advanced risk analytics can reduce the impact of supply chain disruptions by up to 50% and improve on-time delivery by 20-30%. For a mask manufacturer sourcing materials from multiple continents, this predictive capability is not a luxury but a strategic necessity. Let's explore the pathways to access this transformative technology.

What Types of AI Supply Chain Platforms Are Available?

The market offers a spectrum of solutions, from broad enterprise risk suites to specialized niche platforms. Identifying the right type is the first step to access.

How Do Comprehensive Enterprise Suites Compare to Specialized Platforms?

- Comprehensive Enterprise Suites (e.g., SAP Integrated Business Planning for Supply Chain, Oracle Fusion Cloud SCM): These are modules within larger ERP or SCM systems. They leverage the company's internal transactional data (orders, inventory, shipments) and augment it with external risk data feeds.

- Best For: Large enterprises already deeply embedded in the SAP or Oracle ecosystem.

- Access Path: Typically licensed as part of a broader digital transformation contract with the ERP vendor. Implementation is complex, expensive, and requires significant internal IT alignment.

- Specialized AI Risk Platforms (e.g., Resilinc, Everstream Analytics, Riskmethods): These are best-of-breed solutions focused exclusively on risk. They often have superior AI models trained on vast, proprietary datasets of global events, supplier networks, and logistics patterns.

- Best For: Companies of all sizes for whom supply chain resilience is a top priority, especially those with complex, global networks.

- Access Path: Direct subscription (SaaS) from the platform vendor. Faster to deploy and often more feature-rich in risk-specific analytics.

What About Cloud-Based SaaS Solutions vs. On-Premise Installations?

The overwhelming trend is toward Software-as-a-Service (SaaS) models.

- SaaS (Cloud) Platforms: The vendor hosts the software and data. Users access it via a web browser. Updates are automatic.

- Advantages for Access: Lower upfront cost, rapid deployment (weeks, not years), scalability, and access to the vendor's constantly updated global risk intelligence network. This is the most accessible model for small to mid-sized businesses.

- On-Premise Solutions: The software is installed on the company's own servers.

- Considerations: Higher upfront investment, longer implementation, full internal maintenance responsibility. Now rare except in highly regulated industries with extreme data sovereignty requirements.

For most mask manufacturers and traders, SaaS-based specialized platforms offer the most practical and powerful entry point.

- Considerations: Higher upfront investment, longer implementation, full internal maintenance responsibility. Now rare except in highly regulated industries with extreme data sovereignty requirements.

What Are the Key Steps to Implementation and Integration?

Gaining access is more than just purchasing a license; it's about integrating predictive intelligence into daily decision-making processes.

How is Internal Supply Chain Data Integrated?

The AI needs context to be relevant. The first technical step is data onboarding:

- Supplier Master Data: Providing a clean list of all suppliers (Tier 1, and ideally Tier 2+), their locations (address, geo-coordinates), and the critical parts/materials they supply.

- Item Master and BOM Data: Information on products, bills of materials, and which suppliers provide which components. This allows the platform to perform propagation analysis—simulating how a disruption at a sub-supplier ripples up to affect finished mask production.

- Logistics Data: Connecting to Transportation Management Systems (TMS) or providing key lane data (e.g., shipping routes from Shanghai to Long Beach).

This integration can range from manual CSV uploads to fully automated API connections. Platform vendors usually provide templates and support for this phase.

How are Risk Thresholds and Alerts Customized?

A platform that cries "wolf" for every minor incident will be ignored. Successful implementation requires calibration:

- Defining "Criticality": Not all suppliers or materials are equal. The platform must be configured to reflect your business's unique risk tolerance. A disruption at the factory producing your proprietary nanofiber filter is "critical"; a delay on generic ear-loop elastic may be "medium."

- Setting Alert Rules: Configuring what types of events (e.g., typhoon within 100km of supplier, port strike announced, supplier credit rating downgrade) trigger what level of alert (email, SMS, dashboard flag) and for whom.

This customization turns generic monitoring into a tailored early-warning system.

What Are the Cost Structures and Vendor Selection Criteria?

Understanding the investment and how to evaluate potential partners is crucial for making a sound decision.

What are Typical Pricing Models for SaaS Platforms?

Costs are rarely simple and are based on multiple factors:

- Core Subscription Fee: Often based on the number of users (seats) and/or the number of suppliers or sites being monitored.

- Data & Intelligence Tiers: Access to more advanced risk data (e.g., sub-tier supplier mapping, deep financial health scores, highly granular weather modeling) may be in premium tiers.

- Implementation & Onboarding Fees: One-time fees for initial setup, data migration, and configuration.

- Support Fees: Annual fees for technical support and software updates.

Total Cost of Ownership (TCO) can range from tens of thousands of dollars annually for a small business with basic monitoring to hundreds of thousands for a large enterprise with full-scale integration and premium data. Always request detailed proposals and clarify what is included.

What Technical and Strategic Criteria Should Guide Selection?

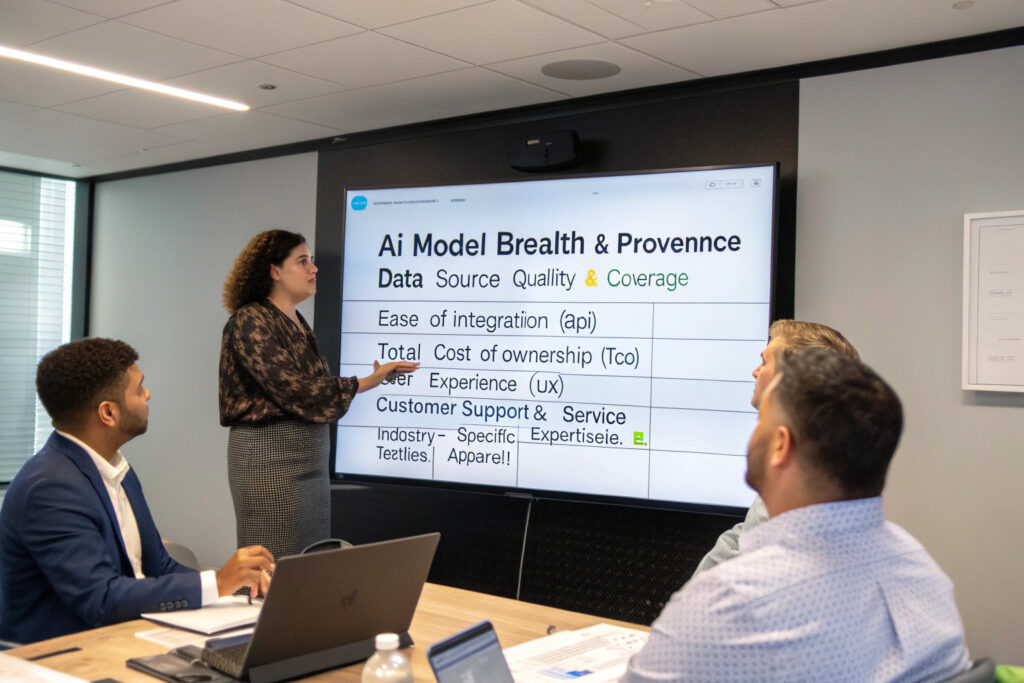

Beyond cost, evaluate vendors on:

- AI and Data Provenance: Where does their data come from? How is their machine learning model trained and validated? Ask for case studies on prediction accuracy.

- Integration Capabilities (APIs): How easily will it connect to your existing ERP, PLM, or TMS systems? Robust, well-documented APIs are essential for seamless data flow.

- User Experience (UX) and Actionability: The best insights are useless if no one uses the platform. The interface should be intuitive, and alerts should be paired with recommended actions (e.g., "Diversify sourcing for this component," "Expedite air freight for this shipment").

- Industry Relevance: Some platforms have stronger capabilities in specific verticals (e.g., high-tech, automotive, pharmaceuticals). Seek references from companies in manufacturing or textiles.

How Can Smaller Businesses Access Advanced Capabilities?

Large enterprise platforms can be cost-prohibitive for SMEs. However, the market is evolving to serve smaller players.

Are There Scalable or Modular Solutions for Mid-Market Companies?

Yes. Many vendors now offer:

- Tiered Subscription Plans: Entry-level plans that monitor a limited number of critical suppliers and provide essential alerts, with the option to scale up.

- Focus on Critical Path: Instead of monitoring the entire supply base, these solutions help you identify and deeply monitor the 20% of suppliers that represent 80% of your risk (the "critical path").

- Partnerships through Logistics Providers: Some freight forwarders or 3PLs (like DHL Resilience360) offer risk analytics as a value-added service to their customers, providing a more accessible entry point.

What Role Do Industry Consortia or Group Purchasing Organizations Play?

Smaller manufacturers, especially in niche sectors, can gain leverage through collective action.

- Group Access: An industry association or purchasing consortium can negotiate a group license for a risk platform, making the per-company cost much lower.

- Shared Intelligence: Some platforms allow for anonymous, aggregated benchmarking. Members can see how their risk profile compares to peers in the same industry, which is invaluable context.

This is a particularly promising model for clusters of manufacturers, such as those in Keqiao's textile district.

Conclusion

Accessing AI-powered supply chain risk prediction platforms is a strategic process that involves selecting the right type of solution (with SaaS-based specialized platforms being the most accessible for many), diligently planning for data integration and process customization, and carefully evaluating vendors based on both technical capabilities and strategic fit. For businesses dependent on global sourcing, the investment is justified by the potential to avoid costly disruptions, reduce excess inventory buffers, and make more confident, proactive decisions. As these platforms become more sophisticated and scalable, they are transitioning from an enterprise-only tool to a critical component of competitive advantage for businesses of all sizes.

Ready to explore how an AI-powered supply chain risk platform can secure your mask manufacturing and sourcing operations? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Our team can share insights from our own risk management practices and connect you with platform partners suited to your business scale and needs.