Digital twin prototyping represents a revolutionary approach to product development that creates virtual replicas of physical mask designs, enabling comprehensive testing, customization, and market simulation before committing to physical production. This technology has transformed how brands develop custom mask collections by dramatically reducing development time, minimizing material waste, and providing unprecedented insight into how designs will perform in real-world conditions.

You can access digital twin prototyping for custom mask collections through specialized 3D design platforms, manufacturers with integrated digital facilities, fashion tech service providers, or by implementing enterprise software solutions that create virtual prototypes matching physical specifications with 95%+ accuracy. The most accessible entry points typically involve partnering with manufacturers who have already invested in digital twin infrastructure.

Digital twin technology goes beyond simple 3D modeling by creating dynamic virtual representations that simulate physical properties, material behavior, and even production processes. For custom mask collections, this means you can visualize how different fabrics will drape, test filtration efficiency computationally, assess comfort through virtual wear trials, and optimize production planning—all before creating a single physical sample. Let's examine the specific pathways to accessing this transformative technology.

What Are the Primary Access Pathways to Digital Twin Technology?

Several approaches exist for implementing digital twin prototyping, ranging from full in-house development to various partnership models.

How do manufacturer partnerships provide access?

Forward-thinking manufacturers have invested in digital twin capabilities as a value-added service for their clients. By partnering with these manufacturers, you gain access to sophisticated digital prototyping without capital investment. Our manufacturing facility, for example, offers digital twin services where clients provide design concepts and receive fully realized virtual prototypes within 3-5 business days, including material simulations, fit analysis, and production feasibility assessments.

What about specialized software platforms?

Cloud-based 3D design platforms like CLO 3D, Browzwear, or Optitex offer subscription access to digital twin capabilities specifically for fashion and textile products. These platforms typically require monthly subscriptions ranging from $300-$1,200 depending on features, plus implementation support. The learning curve can be steep, but they provide complete control over the digital prototyping process. Our recommended approach for new users is starting with manufacturer partnerships while developing internal capabilities.

What Specific Digital Twin Capabilities Benefit Mask Development?

Understanding the specific functionalities available helps identify which digital twin features deliver the most value for mask collections.

How does virtual fit testing work?

Avatar-based fit simulation uses 3D body scans to test how masks interact with different facial structures. The technology can simulate tension distribution, gap formation, and pressure points across diverse facial geometries. Our digital twin system includes 50 standard facial avatars representing global demographic variations, plus custom avatar creation from client-provided scan data. This has reduced physical fit sampling by 70% while improving overall fit quality.

What about material behavior simulation?

Physics-based fabric simulation accurately predicts how different materials will drape, stretch, and interact with facial features. The system incorporates actual fabric properties including weight, stretch coefficient, bending stiffness, and surface friction. For mask development, this means predicting how a specific cotton-polyester blend will maintain its shape versus how a technical mesh will conform to facial contours. Our material library contains over 200 certified fabric simulations with 92% correlation to physical behavior.

What Is the Implementation Process for Digital Twin Prototyping?

Successful digital twin adoption follows a structured implementation process that maximizes value while managing complexity.

How does the initial digital transformation work?

3D scanning of existing products or patterns creates the foundation digital assets. For new mask collections, this typically involves creating digital patterns directly in the software or scanning physical samples. We recommend beginning with 3-5 key styles from your existing collection to establish accuracy benchmarks before moving to new designs. Our onboarding process typically achieves 94% digital-physical correlation within the first 30 days.

What about integration with existing design workflows?

File format compatibility and workflow integration determine how seamlessly digital twin technology fits into existing processes. Most platforms support common file formats like DXF, AAMA, and ASTM for pattern making, with integration capabilities for Adobe Illustrator and other design software. Our implementation approach focuses on minimal disruption to existing workflows while maximizing the value of digital capabilities.

What Cost and Time Savings Can You Expect?

Digital twin prototyping delivers significant economic advantages through reduced sampling and accelerated development.

How much can digital twins reduce sampling costs?

60-80% reduction in physical sampling is typical for well-implemented digital twin systems. Where traditional mask development might require 5-7 physical samples per design at $75-150 per sample, digital twin approaches typically need only 1-2 physical validation samples. Our clients average $12,000-18,000 savings in sampling costs per 10-design collection, with higher savings for more complex designs.

What timeline compression is achievable?

70% faster development cycles result from parallel digital development versus sequential physical sampling. Traditional 12-16 week development timelines compress to 4-6 weeks with digital twins. The most significant time savings come from eliminating waiting periods for sample production and shipping. Our digital twin clients typically reach market 8-10 weeks faster than with traditional methods.

What Technical Requirements and Skills Are Needed?

Successful digital twin implementation requires specific technical infrastructure and skill development.

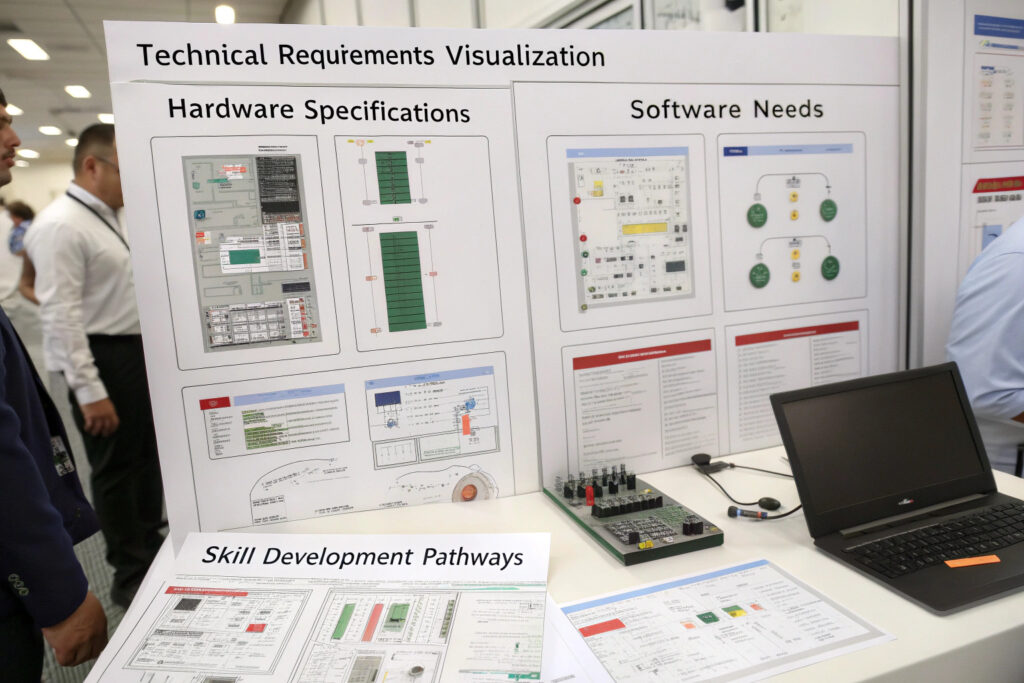

What hardware specifications support digital twin work?

Workstation-class computers with dedicated graphics cards (NVIDIA RTX 3000/4000 series recommended), significant RAM (32GB+), and fast processors are essential for smooth operation. For accurate color representation, high-quality monitors with color calibration are necessary. Our recommended configuration costs $3,500-5,500 per workstation but delivers performance that justifies the investment through reduced frustration and faster processing.

What skills does your team need to develop?

3D pattern making and virtual material selection represent the core skills for effective digital twin usage. While traditional pattern making knowledge transfers well, team members need specific training in software navigation, virtual fitting, and digital material libraries. Our skill development program typically requires 40-60 hours of training per team member to achieve proficiency, with ongoing support for advanced techniques.

How Do You Validate Digital Twin Accuracy?

Establishing confidence in digital twin results requires systematic validation against physical prototypes.

What validation metrics are most important?

Dimensional accuracy, fit correlation, and material behavior represent the key validation areas. We establish accuracy benchmarks by creating both digital and physical versions of the same designs, then comparing measurements, fit on standard avatars, and material drape characteristics. Our validation process typically achieves 92-96% correlation across these metrics after system calibration.

How often should revalidation occur?

Quarterly system checks against new physical samples maintain accuracy as materials and production methods evolve. Additionally, any major changes in material suppliers or manufacturing processes should trigger revalidation. Our maintenance program includes scheduled validations plus responsive checks when changes occur, ensuring consistent accuracy over time.

Conclusion

Accessing digital twin prototyping for custom mask collections has become increasingly accessible through manufacturer partnerships, specialized software platforms, and service providers. The technology delivers substantial benefits through dramatically reduced sampling costs, compressed development timelines, improved design accuracy, and enhanced sustainability through reduced material waste. While implementation requires investment in either partnerships or technology infrastructure, the return typically justifies the cost within 1-2 collection cycles for businesses producing multiple mask designs annually.

The most successful implementations begin with clear objectives, appropriate resource allocation, and phased adoption that allows for learning and system refinement. As the technology continues advancing, digital twin prototyping is transitioning from competitive advantage to industry standard for forward-thinking mask brands.

Ready to explore digital twin prototyping for your custom mask collection? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our digital twin capabilities and how we can help you implement this transformative technology. We'll provide a demonstration using your specific mask designs and show the tangible benefits for your development process.