The textile dyeing industry is notoriously water-intensive, with traditional processes consuming 100-150 liters of water per kilogram of fabric while generating heavily contaminated wastewater. Implementing circular water systems in mask dyeing represents both an environmental imperative and economic opportunity, transforming linear "take-make-dispose" processes into closed-loop systems that recover, treat, and reuse water multiple times.

Implementing circular water systems in mask dyeing involves installing water recycling infrastructure, adopting low-liquor ratio dyeing machines, implementing advanced filtration technologies, recovering heat and chemicals from wastewater, and redesigning dyeing processes for water efficiency. These systems typically reduce freshwater consumption by 70-90% while simultaneously lowering energy use and chemical consumption.

The transition to circular water systems requires both technological investment and process reengineering, but delivers substantial returns through reduced water acquisition costs, lower wastewater treatment expenses, decreased energy consumption, and enhanced compliance with increasingly stringent environmental regulations. Let's examine the specific components and implementation strategies for creating circular water systems in mask dyeing operations.

What Technologies Enable Water Recycling in Dyeing Processes?

Multiple technologies work together to create closed-loop water systems that minimize freshwater intake and wastewater discharge.

How do membrane filtration systems work?

Advanced membrane technologies including ultrafiltration (UF), nanofiltration (NF), and reverse osmosis (RO) remove dyes, chemicals, and impurities from wastewater to produce water pure enough for reuse in dyeing. UF removes suspended solids and large molecules, NF targets dye molecules and divalent salts, while RO eliminates monovalent salts and the smallest contaminants. When implemented in series, these systems can recover 85-95% of wastewater for reuse. Our installation recovers 90% of dyeing wastewater while maintaining water quality suitable for even sensitive dyeing processes.

What role do evaporators and crystallizers play?

Vacuum evaporators concentrate wastewater by boiling at reduced pressure and temperature, recovering distilled water for reuse while concentrating remaining dissolved solids. Crystallizers further process these concentrates to separate salts for potential reuse or safe disposal. These thermal processes typically achieve 95-98% water recovery rates, though they require significant energy input. Our hybrid system uses waste heat from other processes to power evaporation, reducing the energy penalty by 40%.

How Can Dyeing Processes Be Optimized for Water Efficiency?

Process modifications often deliver the most immediate water reductions while making recycling systems more effective.

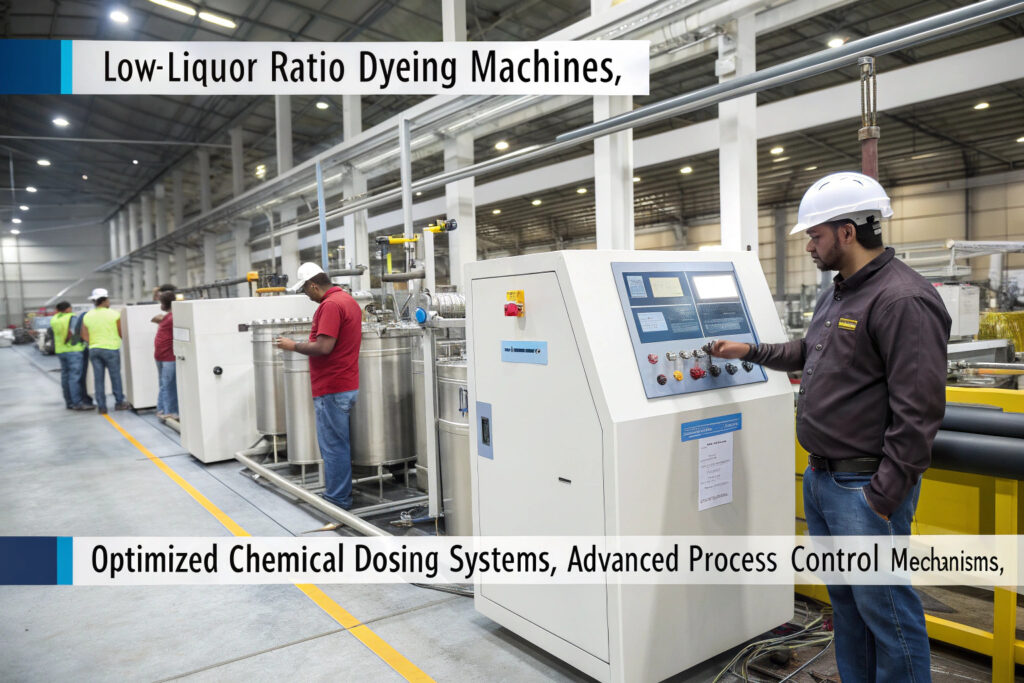

What are low-liquor ratio dyeing machines?

Advanced dyeing equipment with liquor ratios of 1:3 to 1:5 (kg fabric: liters water) dramatically reduce water consumption compared to conventional machines operating at 1:8 to 1:15 ratios. These systems achieve better dye penetration through improved circulation and pressure, using less water while maintaining color quality. Our transition to low-liquor ratio machines reduced water consumption by 55% while improving dye uniformity and reducing chemical usage by 20-30%.

How does process control optimization help?

Automated dosing and monitoring systems ensure precise application of dyes and chemicals, minimizing excess that would require additional rinsing and water treatment. Real-time monitoring of dye bath exhaustion allows for optimal process termination, preventing unnecessary water consumption. Our implementation of automated process control reduced water consumption by 25% and chemical usage by 15% while improving reproducibility.

What Water Treatment Strategies Enable Multiple Reuse Cycles?

Effective treatment is crucial for maintaining water quality through multiple reuse cycles without compromising dyeing results.

How are dyes and chemicals removed for reuse?

Combined physical-chemical-biological treatment creates water suitable for high-quality dyeing applications. Coagulation-flocculation removes suspended solids and some dissolved dyes, activated carbon adsorption eliminates remaining color, and advanced oxidation processes break down persistent organic compounds. Our treatment train produces water with color removal >99% and COD reduction of 85-92%, making it suitable for even light shade dyeing.

What about salt recovery and reuse?

Selective membrane processes combined with evaporative crystallization enable recovery and reuse of salts used in cotton dyeing processes. NF membranes can separate salt solutions from dye residues, allowing salt recovery rates of 70-85%. This not only reduces salt consumption and discharge but also improves the economics of water recycling by recovering valuable chemicals. Our salt recovery system reduces salt purchases by 65% while eliminating salt discharge issues.

How Can You Implement Circular Systems in Existing Facilities?

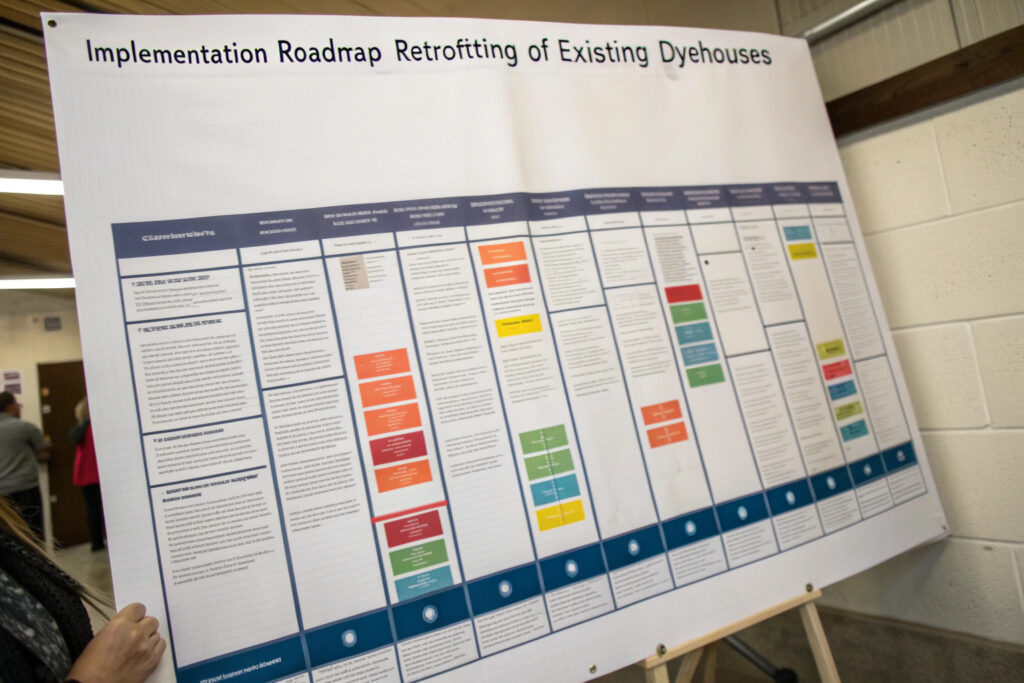

Retrofitting circular water systems requires careful planning to minimize disruption while maximizing effectiveness.

What's the optimal implementation sequence?

Phased implementation beginning with the most water-intensive processes typically delivers the fastest return on investment. Start with preparation and rinsing stages where water quality requirements are lower, then expand to dyeing processes as treatment capabilities improve. Our recommended sequence: (1) Water mapping and audit, (2) Low-cost efficiency measures, (3) Rinse water recycling, (4) Dye bath reuse, (5) Comprehensive recycling. This approach typically achieves 50% water reduction before major capital investment.

How can space constraints be addressed?

Compact, modular treatment systems designed for textile applications can often be integrated into existing facilities with minimal structural modifications. Containerized treatment plants and vertical membrane systems maximize treatment capacity within limited footprints. Our containerized UF-RO system processes 50 m³/day within a 40-foot container space, making circular water systems feasible even for space-constrained urban dyehouses.

What Are the Economic Considerations and ROI?

While circular water systems require significant investment, the economic returns often justify the expenditure.

What is the typical investment range?

System costs vary widely based on capacity and treatment requirements, ranging from $150,000-$500,000 for small to medium dyehouses processing 1,000-5,000 kg/day. Comprehensive systems with thermal recovery and salt recycling typically cost $750,000-$2,000,000. However, government incentives and green financing options can reduce net costs by 20-40%. Our analysis shows typical payback periods of 2-4 years through reduced water, energy, and chemical costs.

How do operational savings compare to costs?

Significant reduction in operational expenses typically includes 70-90% lower water procurement costs, 60-80% reduced wastewater treatment fees, 20-40% lower energy consumption through heat recovery, and 15-30% chemical savings through recovery and optimized dosing. For a medium-sized dyehouse processing 3,000 kg/day, annual savings typically range from $75,000-$150,000, making the investment highly attractive despite the initial capital requirement.

What Certification and Compliance Advantages Exist?

Circular water systems provide significant regulatory and marketing benefits beyond direct economic returns.

How do circular systems simplify regulatory compliance?

Dramatically reduced wastewater discharge minimizes permitting requirements and eliminates concerns about meeting increasingly stringent discharge standards. Many regions offer streamlined permitting or reduced fees for facilities implementing comprehensive water recycling. Our clients with closed-loop systems report 80% fewer compliance issues and significantly reduced regulatory oversight.

What sustainability certifications can be achieved?

Advanced water management enables certification under leading sustainability standards including Bluesign, Oeko-Tex STeP, and ZDHC (Zero Discharge of Hazardous Chemicals). These certifications provide market access to environmentally conscious brands and often justify price premiums of 10-25%. Our certified facilities consistently report stronger buyer relationships and improved competitive positioning.

Conclusion

Implementing circular water systems in mask dyeing processes represents a strategic investment that delivers environmental, economic, and competitive benefits. Through technology integration, process optimization, and phased implementation, dyehouses can reduce freshwater consumption by 70-90% while simultaneously lowering operational costs and enhancing sustainability credentials. The transition requires capital investment and technical expertise but typically delivers attractive returns through resource savings, regulatory compliance, and market differentiation.

As water scarcity increases and environmental regulations tighten, circular water systems are transitioning from competitive advantage to business necessity in textile dyeing. Companies that proactively implement these systems position themselves for long-term viability while contributing to broader environmental sustainability goals.

Ready to explore circular water system implementation for your mask dyeing operations? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our water recycling expertise and how we can help you transition to more sustainable, cost-effective dyeing processes. We'll provide specific recommendations based on your facility, processes, and sustainability objectives.