Seasonal fabric mask collections face the unique challenge of requiring design flexibility and rapid turnover while managing manufacturing minimums that often favor consistent, year-round production. High MOQs can lock up capital in slow-moving inventory and limit your ability to test new designs or respond to fleeting fashion trends. Fortunately, several strategic approaches can significantly reduce these minimums while maintaining quality and design integrity.

You can reduce MOQs for seasonal fabric mask collections by implementing modular design systems, utilizing manufacturer stock materials, participating in collective production runs, employing digital printing technologies, negotiating split production arrangements, and developing strategic manufacturer partnerships. These approaches can typically reduce minimums by 40-70% while preserving the seasonal appeal and design distinctiveness of your collections.

The key to reducing MOQs lies in understanding what drives manufacturer minimums and strategically minimizing the elements that create those thresholds. By focusing on the most impactful constraints and developing creative solutions for each, seasonal collections can achieve both design freshness and production efficiency. Let's examine the specific strategies that deliver meaningful MOQ reductions.

What Modular Design Approaches Lower Production Minimums?

Modular design transforms your collection architecture from custom creations to configurable systems that dramatically reduce setup requirements.

How does component standardization reduce MOQs?

Standardized base patterns with interchangeable design elements allow manufacturers to produce components in larger quantities across multiple designs. For example, using the same mask shape across your collection with different printed fabrics, or creating separate decorative elements that attach to standard bases. This approach has reduced our seasonal collection MOQs from 1,000-2,000 per design to 300-500 per design while actually increasing perceived variety.

What about colorway and pattern strategies?

Strategic color palette development using manufacturer stock dyes rather than custom colors eliminates dye lot minimums that often drive MOQs higher. Similarly, developing patterns that work within standard printing dimensions avoids special setup requirements. Our most successful seasonal collections use 4-5 core colors in different combinations across 8-10 designs, creating the appearance of greater variety while maintaining production efficiency.

How Can Manufacturer Relationships Lower Seasonal MOQs?

Developing the right type of manufacturer relationships transforms MOQ negotiations from transactional discussions to strategic partnerships.

What partnership approaches increase flexibility?

Annual volume commitments with quarterly collection releases provide manufacturers with production predictability that justifies lower per-collection MOQs. By guaranteeing a certain annual volume spread across multiple seasons, manufacturers can reserve capacity and plan material purchases more efficiently. Our partnered clients typically achieve 50-60% lower MOQs compared to seasonal-only purchasers.

How does transparent planning help?

Sharing seasonal calendars and development plans 6-9 months in advance allows manufacturers to schedule your collections during natural production valleys, when they're more flexible with minimums. This approach has been particularly effective for manufacturers with seasonal patterns themselves, such as those who produce winter accessories and have available capacity during mask production seasons.

What Production Technologies Enable Lower Minimums?

Advances in manufacturing technologies have created new possibilities for economically producing smaller batches.

How does digital printing reduce setup costs?

No-minimum digital printing eliminates the screen setup costs that traditionally required high MOQs to amortize. Where screen printing might require 500-1,000 pieces minimum per design, digital printing can economically produce as few as 50-100 pieces. This technology has been revolutionary for seasonal collections, allowing intricate patterns and photographic designs without massive minimums. Our digital printing program starts at just 75 pieces per design.

What about cutting and assembly innovations?

Laser cutting and automated pattern nesting reduce material waste and setup time for small batches, making lower MOQs economically viable. These technologies allow manufacturers to efficiently cut multiple designs from the same fabric with minimal waste. Our manufacturing partners using these technologies have reduced their cutting minimums by 40-60% compared to traditional manual cutting operations.

What Collective Production Strategies Work?

Pooling resources with other brands or leveraging manufacturer consolidation programs can achieve economies of scale without individual large commitments.

How do manufacturer consolidation programs work?

Shared production runs where manufacturers combine similar orders from multiple brands allow each participant to benefit from volume pricing and lower effective MOQs. This works particularly well for basic mask shapes where brands differ primarily through fabric selection and branding. Our consolidation program enables brands to participate with as few as 200 pieces per design while accessing pricing typically requiring 1,000+ pieces.

What about component pooling strategies?

Shared component inventory across multiple seasonal collections or even multiple brands reduces material minimums for everyone. For example, several brands might collectively order a special elastic color that each uses in their collections, or share custom developed nose wires. This approach has helped our clients reduce their effective MOQs by 30-40% for collections using specialized components.

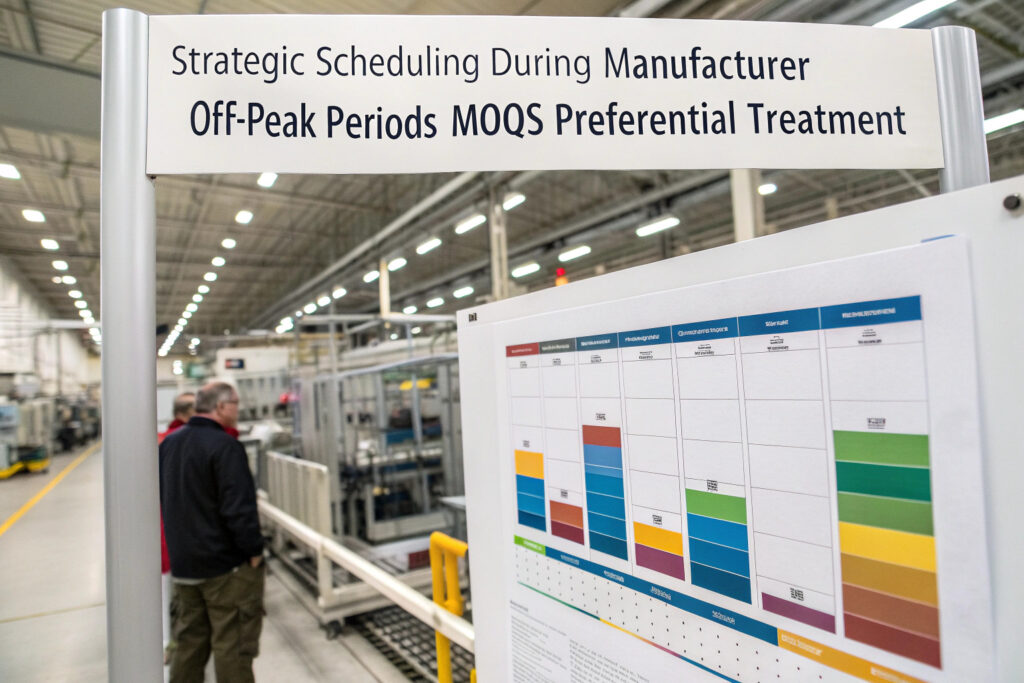

What Timing Strategies Optimize Production Flexibility?

Strategic timing of production and inventory management can significantly impact achievable MOQs.

How does off-peak production scheduling help?

Manufacturing during seasonal slow periods typically yields significantly more MOQ flexibility as factories seek to maintain workforce and equipment utilization. For most mask manufacturers, January-February and June-July represent natural slower periods where minimums may be 20-30% lower. Our production planning system identifies these optimal timing windows for each manufacturing partner.

What about phased production approaches?

Split production runs with an initial smaller quantity followed by a potential reorder allow you to test market response before committing to full volumes. Many manufacturers will accommodate this approach if you commit to the potential full volume upfront, with the reorder at the same pricing. This strategy has reduced our clients' initial inventory risk by 50-70% while maintaining the option to fulfill unexpected demand.

What Material Selection Strategies Reduce Minimums?

Strategic material choices significantly impact MOQs by eliminating the constraints that drive minimum quantities.

How does stock fabric utilization help?

Manufacturer in-stock fabric programs eliminate fabric minimums entirely, as you're using materials already purchased for other clients or maintained as standard inventory. Most quality manufacturers maintain 50-100 fabric options in stock, with MOQs based only on production efficiency rather than material minimums. Our stock fabric program offers MOQs as low as 150 pieces compared to 500+ for custom fabrics.

What about remnant and overstock opportunities?

Strategic use of fabric remnants from larger production runs can create limited edition seasonal items with virtually no MOQ. Many manufacturers have leftover fabrics from large orders that they'll sell for limited runs at significantly reduced minimums. Our remnant program has enabled some seasonal collections with as few as 75 pieces per design at 40-60% lower fabric costs.

Conclusion

Reducing MOQs for seasonal fabric mask collections requires a multifaceted approach combining modular design, strategic manufacturer relationships, appropriate production technologies, collective production strategies, optimal timing, and smart material selection. The most effective implementations typically combine several of these approaches to achieve 40-70% MOQ reductions while maintaining design integrity and quality.

The ability to produce smaller seasonal collections transforms your business model, allowing faster response to trends, reduced inventory risk, and more frequent collection refreshes. By implementing these strategies systematically, seasonal mask collections can achieve both creative freedom and production efficiency.

Ready to develop seasonal fabric mask collections with optimized MOQs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our low-MOQ seasonal production programs and how we can help you create compelling collections with minimum inventory commitment. We'll provide specific MOQ scenarios based on your design requirements and seasonal strategy.