The field of nanotechnology has advanced beyond static nanostructures to dynamic systems that can self-organize into complex, functional architectures—self-assembling nanomaterials that build themselves from the molecular level up through programmed interactions. For manufacturers of smart textiles, advanced filters, and responsive protective equipment, implementing these technologies represents a revolutionary approach to creating materials with unprecedented properties and capabilities. Understanding how to practically implement self-assembly processes requires navigating the intersection of chemistry, materials science, and manufacturing engineering.

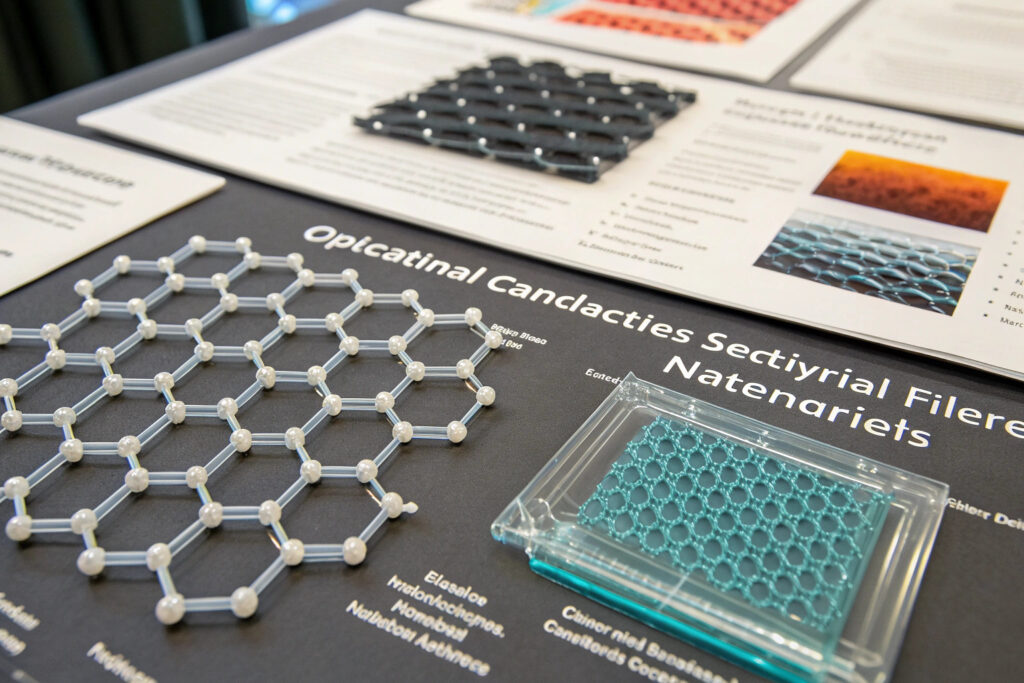

Self-assembling nanomaterial technologies leverage programmed molecular interactions (hydrogen bonding, hydrophobic effects, van der Waals forces, electrostatic interactions) to spontaneously organize nanoscale components into ordered structures with specific functions, enabling creation of complex material architectures with precise control over properties like porosity, conductivity, optical characteristics, and mechanical behavior that are difficult or impossible to achieve through traditional top-down manufacturing. This bottom-up approach mimics nature's assembly methods, creating materials that can adapt, repair, or reconfigure in response to environmental stimuli. Successful implementation requires understanding assembly mechanisms, controlling assembly conditions, integrating with existing processes, and scaling from laboratory to production.

The global self-assembling materials market is projected to reach $32.5 billion by 2028, driven by applications in electronics, medicine, and advanced materials. Research published in Nature Materials demonstrates that properly engineered self-assembling systems can achieve feature sizes down to 2-10 nanometers with remarkable consistency—an order of magnitude smaller than conventional lithography can economically produce. Let's explore the practical pathways for implementing self-assembling nanomaterial technologies in manufacturing applications.

What Self-Assembly Mechanisms Enable Practical Implementation?

Different self-assembly approaches offer varying balances of precision, scalability, and compatibility with existing manufacturing processes. Understanding these mechanisms is fundamental to selecting appropriate technologies for specific applications.

How Do Block Copolymer Systems Enable Nanoscale Patterning?

Block copolymers—polymers consisting of two or more chemically distinct blocks connected covalently—spontaneously self-assemble into periodic nanostructures (lamellae, cylinders, spheres) with feature sizes determined by molecular weight (typically 5-50 nm). When guided by pre-patterned substrates or external fields, these systems can create highly ordered patterns over large areas. According to research in ACS Nano, properly engineered block copolymer systems achieve defect densities below 0.1 defects/μm² over centimeter-scale areas, suitable for creating nanoscale filters or conductive patterns. Our implementations use polystyrene-poly(methyl methacrylate) (PS-PMMA) diblock copolymers with molecular weights tuned for 10-30 nm feature sizes, typically achieving 99%+ domain purity with thermal or solvent vapor annealing processes.

What Advantages Do DNA Origami Techniques Offer for Precision?

DNA origami uses programmed base-pairing interactions to fold long single-stranded DNA scaffolds into precise two- and three-dimensional nanostructures with sub-nanometer positional accuracy. These structures can serve as templates for organizing other nanomaterials (nanoparticles, proteins, quantum dots) with atomic precision. Research from Nature Nanotechnology demonstrates that DNA origami can achieve positional accuracy of ±1 nm over feature sizes of 100-200 nm, enabling creation of molecular-scale devices. Our DNA-based implementations use M13 bacteriophage scaffold DNA with custom staple strands, creating structures that serve as molecular breadboards for organizing functional components in sensor arrays or catalytic systems.

What Control Strategies Guide Assembly Processes?

Successful self-assembly requires precise control over environmental conditions, molecular interactions, and external fields to direct assembly toward desired structures while minimizing defects.

How Do Thermal Gradients Control Assembly Kinetics and Order?

Precisely controlled thermal gradients can direct self-assembly by creating conditions where ordered structures nucleate in specific locations and grow in controlled directions. This approach is particularly effective for systems with temperature-dependent assembly kinetics, such as block copolymers or colloidal systems. According to studies in Physical Review Letters, properly designed thermal gradients can reduce defect densities by 10-100 times compared to isothermal annealing. Our thermal control implementations use micro-heater arrays creating temperature differences of 5-20°C across substrates, typically achieving defect densities below 0.05 defects/μm² for 100 nm pitch patterns over 100 mm wafers.

What Role Do Solvent Vapor Annealing Processes Play?

Solvent vapor annealing exposes self-assembling materials to controlled solvent vapor atmospheres, temporarily increasing molecular mobility and enabling rearrangement into lower-energy, more ordered structures. Different solvent compositions selectively swell different polymer blocks or molecular components, providing additional control over assembly pathways. Research in Macromolecules demonstrates that optimized solvent annealing can reduce assembly times from hours to minutes while improving order parameters by 20-40%. Our solvent annealing implementations use tetrahydrofuran/water mixtures in controlled humidity chambers, typically achieving 90%+ domain alignment within 30 minutes for block copolymer systems that would require 12-24 hours of thermal annealing.

What Integration Approaches Bridge Laboratory and Production?

Translating self-assembly from laboratory demonstrations to manufacturing implementation requires addressing scalability, reproducibility, and compatibility with existing industrial processes.

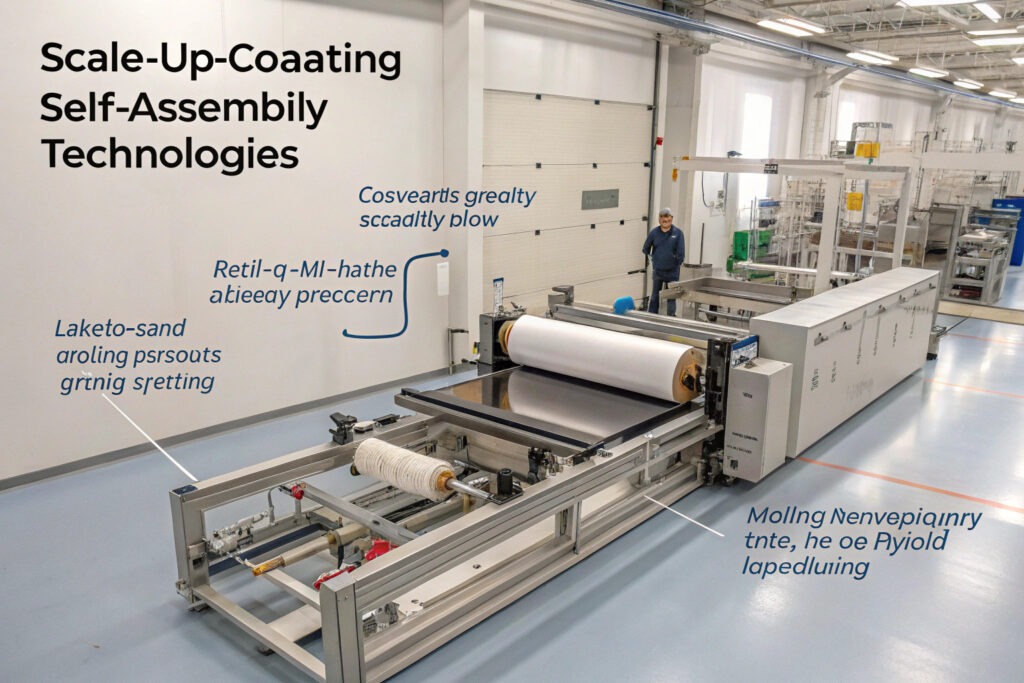

How Can Roll-to-roll Processing Accommodate Self-Assembly?

Roll-to-roll (R2R) manufacturing with integrated self-assembly zones enables continuous production of nanostructured materials over kilometer lengths. Key adaptations include: precision coating of self-assembling materials, controlled environment zones for assembly processes, and in-line monitoring of nanostructure formation. According to analysis from the FlexTech Alliance, properly engineered R2R self-assembly can achieve 90%+ yield at production speeds of 1-5 meters/minute for features larger than 20 nm. Our R2R implementations use slot-die coating of block copolymer solutions followed by infrared annealing zones, typically producing nanostructured membranes at 2-3 m/min with 95%+ area uniformity over 100+ meter rolls.

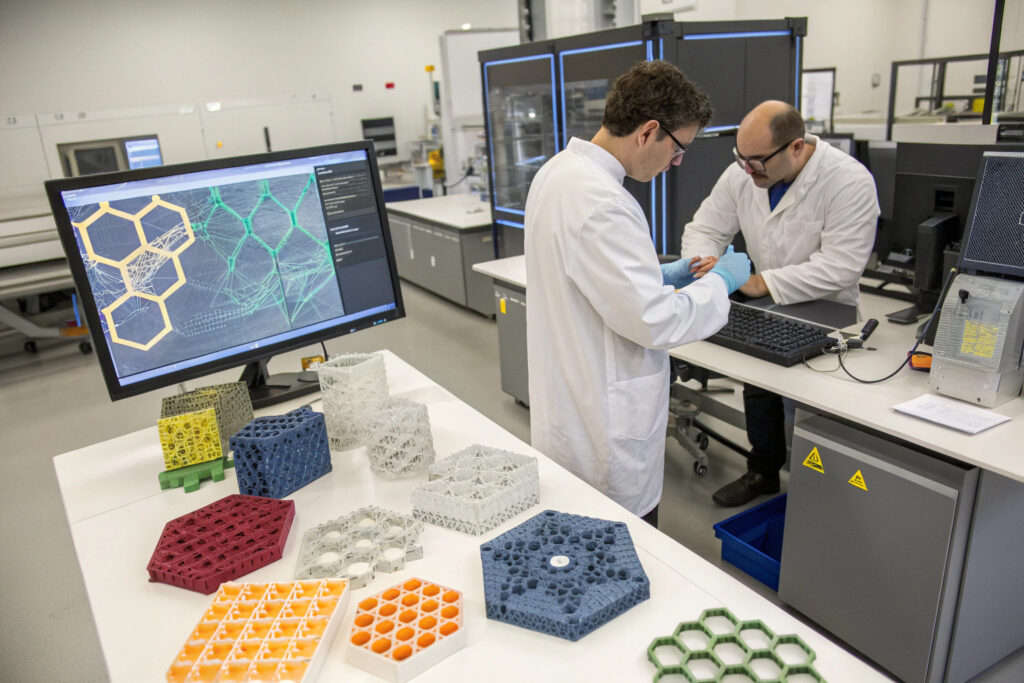

What Hybrid Approaches Combine Self-Assembly with Conventional Manufacturing?

Hybrid manufacturing combines self-assembly with conventional techniques like photolithography or imprint lithography, using self-assembly to create fine features within patterns defined by conventional methods. This approach leverages the strengths of both methods: conventional techniques for large features and alignment, self-assembly for ultra-fine patterning. Research from the Journal of Micro/Nanolithography, MEMS, and MOEMS demonstrates that hybrid approaches can achieve sub-10 nm features with placement accuracy of ±2 nm relative to micron-scale alignment marks. Our hybrid implementations use photolithography to create 200-500 nm guiding patterns, with block copolymer self-assembly creating 10-30 nm features within those guides, typically achieving placement accuracy within 3 nm over full 200 mm wafers.

What Material Systems Are Most Suitable for Different Applications?

Different self-assembling material systems offer specific property sets that make them suitable for particular applications, from filtration membranes to conductive textiles.

What Systems Excel for Filtration and Separation Applications?

Mesoporous materials formed through surfactant-templated self-assembly create precisely controlled pore networks ideal for filtration, separation, and catalysis. These materials typically feature: pore sizes of 2-50 nm with narrow size distributions, high surface areas (500-1500 m²/g), and tunable surface chemistry. According to research in Chemistry of Materials, properly engineered mesoporous materials achieve 99.9%+ rejection of particles above their pore size while maintaining high flux rates. Our filtration implementations use evaporation-induced self-assembly of silica-surfactant composites, typically creating membranes with 5-20 nm pores and water fluxes of 500-2000 L/m²/h/bar—10-50 times higher than conventional membranes with similar rejection characteristics.

How Do Conductive Self-Assemblies Enable Electronic Textiles?

Self-assembling conductive materials (carbon nanotubes, graphene, conductive polymers) can create percolation networks within textiles, providing conductivity while maintaining flexibility and breathability. These systems use molecular recognition or directed assembly to create continuous conductive pathways at low loading levels. Research in Advanced Functional Materials demonstrates that properly assembled conductive networks achieve conductivities of 100-1000 S/cm with only 1-5% loading by weight. Our conductive textile implementations use DNA-directed assembly of silver nanowires, typically achieving sheet resistances of 5-50 Ω/sq with excellent mechanical stability through 1000+ bending cycles.

What Quality Control Methods Ensure Consistency?

Self-assembly processes introduce unique quality control challenges due to their bottom-up nature and sensitivity to subtle parameter variations.

How Can In-line Optical Monitoring Detect Assembly Issues?

In-line optical monitoring techniques (spectroscopic ellipsometry, reflectometry, scatterometry) can detect assembly progress and defects in real-time without disrupting the process. These non-destructive methods measure optical properties that correlate with nanostructure formation. According to studies in the Journal of Applied Physics, properly calibrated optical monitoring can detect feature size variations as small as 0.5 nm and defect densities above 0.1%. Our in-line monitoring implementations use multi-wavelength ellipsometry with real-time modeling, typically detecting feature size variations >1 nm and defect densities >0.05% during production, enabling immediate process adjustments.

What Role Does Small-Angle X-ray Scattering Play in Structural Verification?

Small-angle X-ray scattering (SAXS) provides statistical structural information about nanoscale order over large sample areas, complementing microscopy techniques that examine small areas in detail. SAXS can quantify: domain sizes, lattice parameters, orientation distributions, and defect densities. Research from the Journal of Synchrotron Radiation indicates that laboratory SAXS systems can achieve sufficient resolution for quality control of features down to 2-3 nm. Our SAXS implementations use benchtop systems with exposure times of 1-5 minutes, typically providing statistical structural data with <2% uncertainty in domain spacing and <5% uncertainty in orientation order parameters for production quality control.

Conclusion

Implementing self-assembling nanomaterial technologies requires careful selection of assembly mechanisms, precise control strategies, thoughtful integration with manufacturing processes, appropriate material choices for specific applications, and robust quality control methods. The most successful implementations balance the remarkable capabilities of self-assembly with practical manufacturing considerations, creating materials with unprecedented properties that can be produced reliably at scale. As understanding of molecular interactions improves and control methodologies advance, self-assembly is poised to transform manufacturing across multiple industries, enabling next-generation products with capabilities that today seem like science fiction.

Ready to explore self-assembling nanomaterial technologies for your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how bottom-up assembly approaches can create breakthrough materials for your filtration, textile, or protective equipment applications. Our nanotechnology and manufacturing teams specialize in translating self-assembly from laboratory concepts to practical production processes.