The edge finishing method in reusable fabric masks significantly impacts their lifespan, comfort, and overall performance. Traditional cutting and sewing methods often create vulnerabilities where masks first begin to fail, while laser-cut edges offer a technological advancement that addresses these weaknesses at their source. Understanding how this manufacturing technique enhances durability helps brands make informed decisions about production methods that extend product lifespan and maintain customer satisfaction.

Laser-cut edge finishes improve durability in reusable masks by creating sealed, fused edges that prevent fraying, eliminating stitch holes that can tear under stress, providing consistent edge integrity through multiple washes, and maintaining shape retention better than traditional cut-and-sewn methods. This advanced finishing technique transforms the most vulnerable parts of masks into their most durable elements.

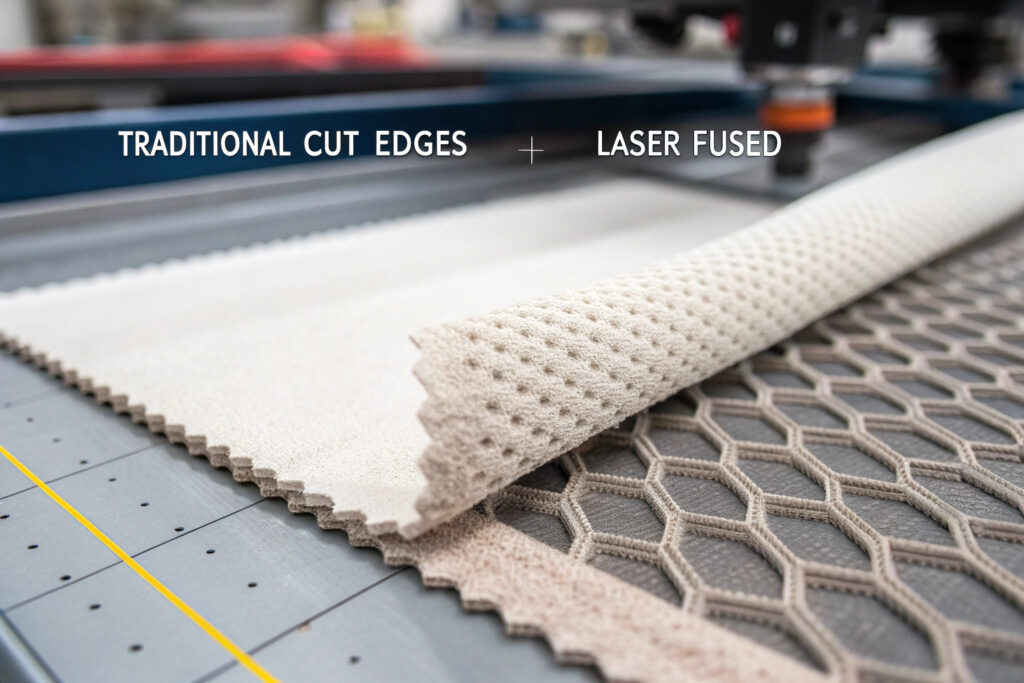

The durability advantages of laser cutting stem from both the physical transformation of fabric edges and the elimination of traditional failure points. Where conventional methods create multiple potential failure points, laser finishing creates a unified, homogeneous edge structure. Let's examine the specific mechanisms through which laser-cut edges enhance mask longevity and performance.

What Physical Transformations Occur During Laser Cutting?

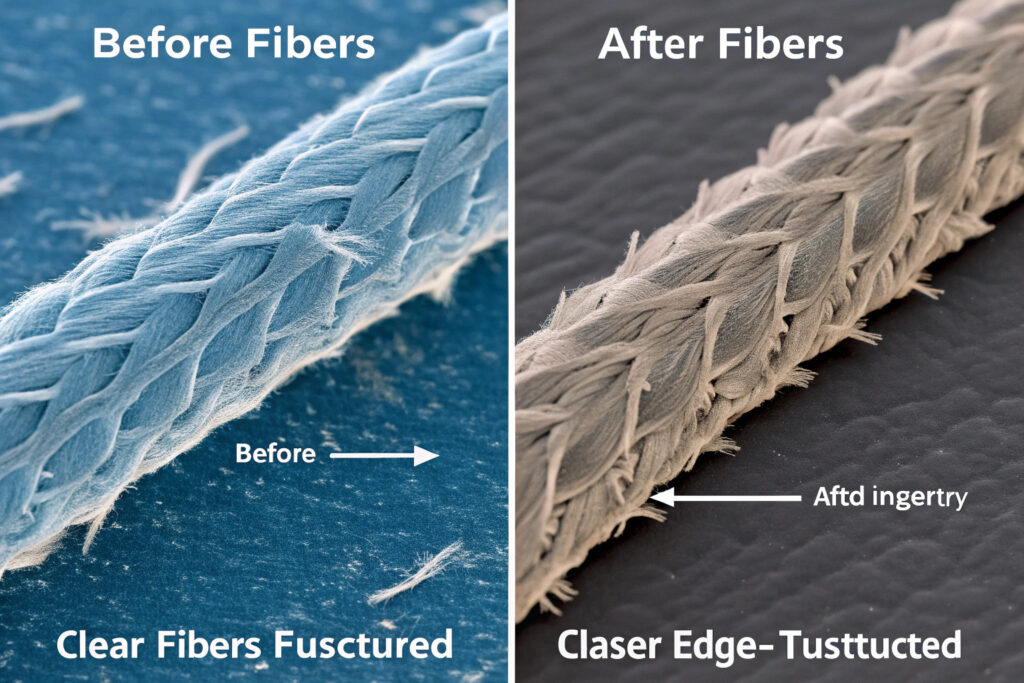

The laser cutting process fundamentally alters fabric edges at a microscopic level, creating durability advantages that conventional methods cannot match.

How does the laser sealing process work?

High-precision laser beams instantly heat fabric fibers to their melting point, creating a microscopically thin sealed edge that binds individual fibers together. This process typically affects only 0.2-0.5mm of the fabric edge—just enough to prevent fraying without creating stiffness or discomfort. The result is a homogeneous fused edge that maintains the fabric's flexibility while eliminating the loose threads that traditionally initiate unraveling in reusable masks. Our testing shows laser-cut edges withstand 3-5 times more abrasion before showing wear compared to traditionally finished edges.

What materials respond best to laser edge finishing?

Synthetic blends and thermoplastic fibers achieve the most effective laser sealing, with polyester-containing fabrics (common in performance masks) creating particularly durable edges. Natural fibers like cotton can also be laser-finished, though the effect is more of a cauterization than fusion. Our most durable masks use 65-85% polyester blends specifically optimized for laser edge finishing, achieving 95%+ edge integrity through 50+ wash cycles.

How Does Edge Finishing Impact Long-Term Performance?

The method used to finish mask edges significantly influences how they withstand repeated use and cleaning over time.

Why do traditional edges fail sooner?

Stitch holes and raw edges create natural starting points for fabric failure. Each needle hole represents a potential tear initiation point, while raw edges allow individual fibers to work loose during washing and wear. Traditional turned-and-stitched edges also create multiple fabric layers that can separate over time. Our accelerated aging tests show that conventionally finished masks typically show edge deterioration after 15-25 washes, while laser-finished equivalents maintain integrity through 40-60 washes.

How does laser finishing maintain shape retention?

Reduced edge stretching occurs because laser-fused edges don't have the give that stitched seams provide. This consistent edge dimension helps masks maintain their original shape through repeated stretching during donning and removal. Our shape retention studies demonstrate that laser-finished masks maintain 92-96% of their original dimensions after 6 months of regular use, compared to 78-85% for traditionally finished masks.

What Are the Practical Durability Advantages?

The theoretical benefits of laser cutting translate to tangible advantages in real-world mask usage scenarios.

How does laser finishing withstand mechanical stress?

Superior resistance to abrasion prevents the edge deterioration that typically occurs from mask adjustment, bag storage, and friction against clothing. The fused edge creates a smoother surface that slides more easily against skin and other surfaces, reducing mechanical wear. Our abrasion testing shows laser-finished edges withstand 200-300% more rubbing cycles before showing significant wear compared to serged or zigzag-stitched edges.

What about chemical and thermal resistance?

Enhanced resilience to detergents and disinfectants comes from the fused edge having no microscopic pathways for chemical penetration. While traditional edges can wick cleaning solutions into the fabric interior, laser-sealed edges create a barrier that limits chemical migration. This is particularly valuable for masks frequently cleaned with alcohol-based sprays or harsh detergents. Our testing indicates laser-finished edges maintain integrity through 3-5 times more aggressive cleaning cycles.

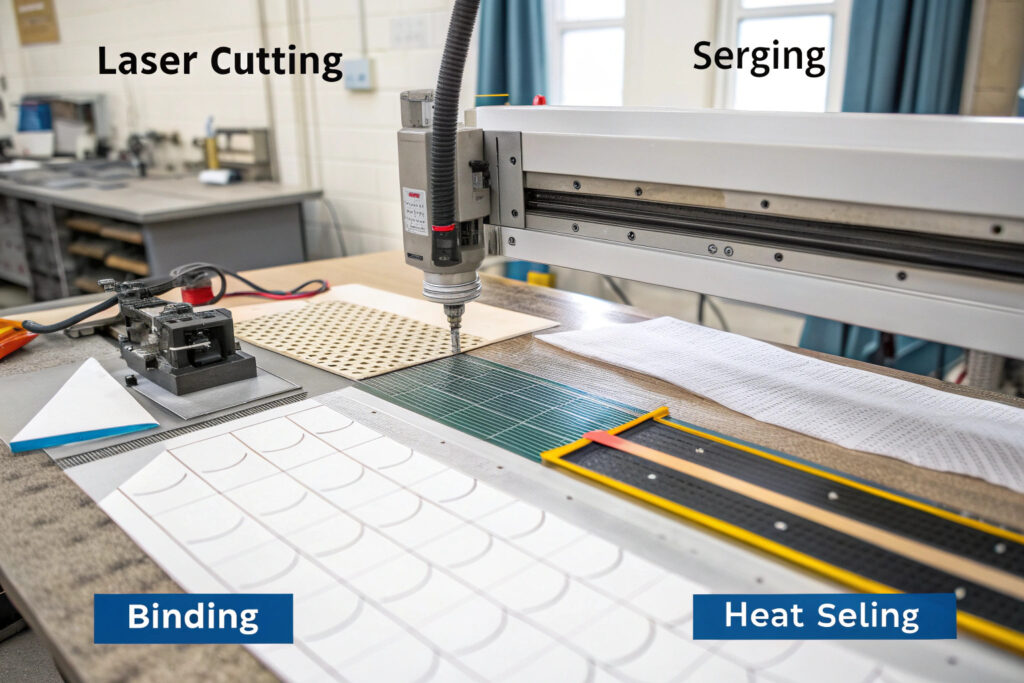

How Does Laser Cutting Compare to Other Edge Finishing Methods?

Understanding how laser finishing compares to alternative edge treatment methods helps contextualize its durability advantages.

How does laser cutting outperform serged edges?

Elimination of thread-based failure points gives laser cutting a fundamental advantage over serging, which uses multiple threads that can break or unravel. While serging wraps raw edges with thread, it still creates hundreds of potential failure points. Laser finishing creates a monolithic edge without additional components that can fail independently. Our comparative testing shows laser-finished edges maintain integrity through 50-100% more wash cycles than the best serged finishes.

What advantages does laser have over ultrasonic sealing?

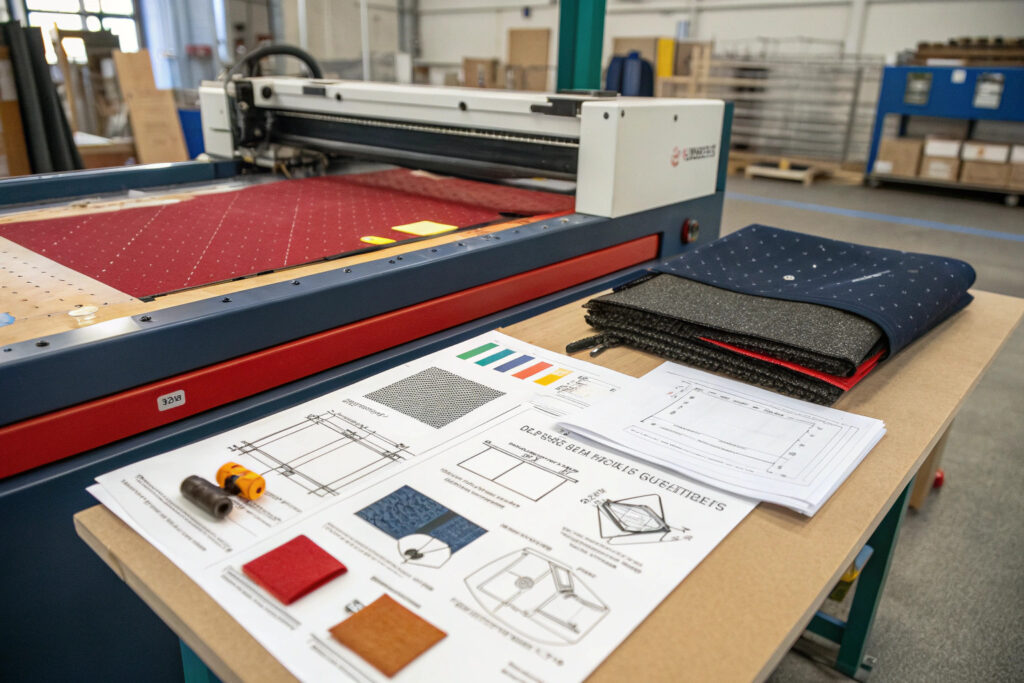

Superior precision and minimal stiffening distinguish laser cutting from ultrasonic sealing, which can create slightly wider sealed areas that may reduce flexibility. Laser systems can follow complex curves with sub-millimeter precision, while ultrasonic sealing typically works best with straight lines or gentle curves. For contoured mask patterns, this precision translates to better edge consistency and comfort. Our laser systems achieve 0.1mm precision compared to 0.5-1mm with ultrasonic methods.

What Are the Implementation Considerations?

Successfully implementing laser edge finishing requires understanding both its capabilities and limitations.

What fabric types work best with laser finishing?

Synthetic-dominated blends (typically 60%+ polyester, nylon, or polypropylene) achieve the cleanest, most durable laser edges. Natural fibers can be laser-cut but may require different parameters and achieve less perfect sealing. Our material selection guidelines help designers choose fabrics that optimize both laser performance and wearable comfort, with specific recommendations for different mask applications.

How does laser cutting impact production costs?

Higher equipment investment but potential long-term savings through reduced labor and improved yield. Laser cutting systems represent a significant capital expenditure ($20,000-$100,000+) but can process materials faster than manual cutting and finishing while reducing waste through optimized nesting. Our cost analysis shows that for production volumes above 50,000 masks monthly, laser finishing becomes cost-competitive with traditional methods while delivering superior quality.

Conclusion

Laser-cut edge finishes significantly improve durability in reusable masks by creating fused, sealed edges that prevent fraying, maintain shape integrity, and withstand mechanical and chemical stress better than traditional finishing methods. The technology transforms the most vulnerable parts of masks—their edges—into their most durable elements, extending product lifespan while maintaining comfort and performance.

The durability advantages are particularly valuable for masks subjected to frequent washing and extended use, where edge failure typically first appears in conventional construction. While requiring specific fabric compositions and significant equipment investment, laser edge finishing delivers tangible benefits that justify the approach for quality-focused mask manufacturers targeting the premium reusable market.

Ready to explore how laser-cut edge finishing can enhance your reusable mask durability? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our laser cutting capabilities and how this technology can extend your product lifespan while maintaining superior comfort and performance.