The plus-size market represents a significant but often overlooked opportunity in the fabric mask industry, with standard "one-size-fits-all" masks frequently failing to provide adequate coverage, comfort, or protection for individuals with larger facial features. Sourcing custom-fit masks for this demographic requires specialized pattern making, expanded size ranges, and understanding of the unique fitting challenges faced by this consumer segment.

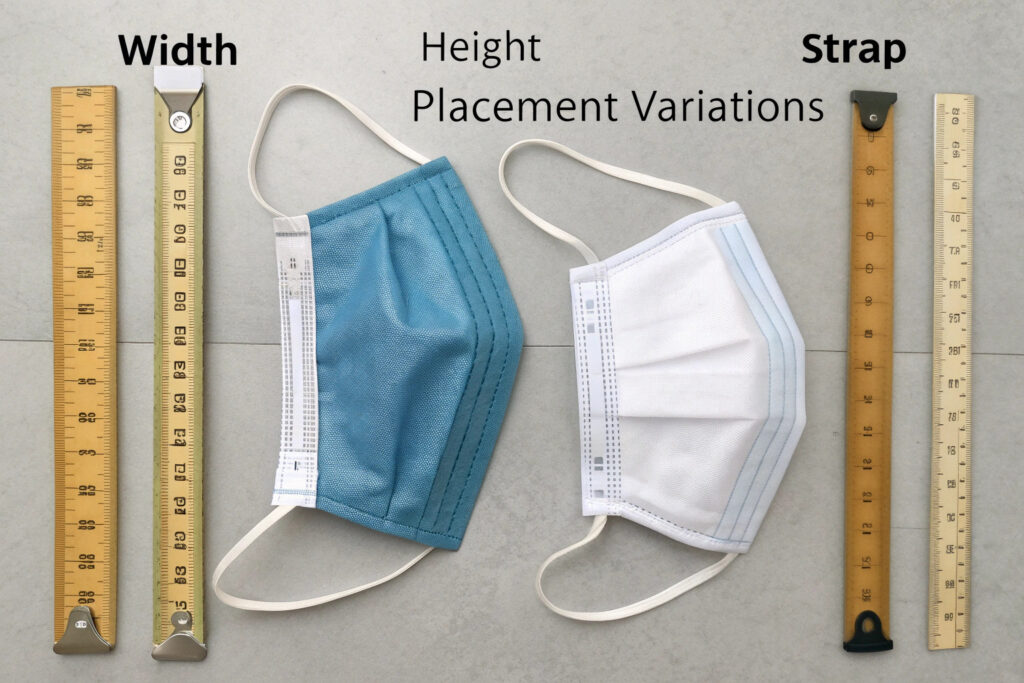

To source custom-fit fabric masks for plus-size markets, partner with manufacturers offering expanded size ranges, specialized pattern engineering for fuller facial features, adjustable features that accommodate diverse face shapes, and testing protocols that validate fit across the target demographic. Successful sourcing addresses the three critical dimensions where standard masks fail plus-size users: width coverage, vertical height, and strap accommodation.

The plus-size mask market isn't simply about scaling up standard patterns—it requires rethinking mask geometry, strap placement, and adjustment systems to accommodate the wider cheekbones, fuller jawlines, and increased facial surface area common in this demographic. Let's examine the specific sourcing considerations that deliver genuine custom fit for plus-size consumers.

What Design Specifications Differentiate Plus-Size Masks?

Plus-size masks require specific dimensional adjustments beyond simple scaling of standard patterns.

How do mask dimensions expand for plus-size fit?

Critical measurement increases include mask width (extending from 7.5-8.5" to 9-11"), vertical height (increasing from 4-4.5" to 5-6"), and nose-to-chin coverage (expanding from 6-7" to 7.5-9"). These dimensional changes ensure complete coverage without gaping at the edges or exposing the chin. Our plus-size pattern library includes three distinct size categories (Large, X-Large, XX-Large) that accommodate the facial dimension diversity within the plus-size demographic.

What about strap length and placement?

Extended strap systems with 2-4" additional length prevent the ear discomfort and mask distortion caused by straps that are too short. Additionally, strategic strap angle adjustments accommodate wider cheekbones and jawlines without creating pressure points. Our plus-size designs feature 12-14" elastic straps compared to the 8-10" straps on standard masks, with attachment points positioned to follow natural facial contours.

What Manufacturing Capabilities Support Plus-Size Production?

Identifying manufacturers with specific expertise in expanded size ranges ensures proper execution of plus-size designs.

What pattern engineering expertise is required?

Advanced grading techniques that go beyond simple proportional scaling create masks that fit the unique proportions of larger faces. This includes independent adjustment of width, height, and depth dimensions to accommodate fuller cheeks while maintaining proper nose and chin seals. Our pattern engineers use 3D facial scanning data from plus-size individuals to create patterns that address real-world fitting challenges rather than theoretical scaling.

How do production processes differ?

Specialized equipment settings including wider cutting tables, adjusted sewing machine tensions, and modified pressing equipment accommodate the larger fabric pieces and additional layers in plus-size masks. Manufacturers experienced in plus-size apparel typically have these adaptations already implemented. Our production lines dedicated to plus-size masks achieve the same efficiency as standard mask production through optimized workflows and operator training.

What Materials and Construction Enhance Plus-Size Comfort?

Material selection and construction methods significantly impact comfort and functionality for plus-size mask wearers.

Which fabrics work best for plus-size applications?

Stretch blends with 5-15% spandex accommodate facial movements and variations in facial structure without losing shape. The slight give in these materials prevents the mask from pulling away from the face during talking or expression changes. Our preferred plus-size fabric is a 92% cotton/8% spandex jersey that provides both comfort and maintainance of seal integrity.

How does construction impact plus-size fit?

Strategic seam placement that follows natural facial contours rather than creating straight lines prevents gaping and improves seal. Additional darting or curved seams in the cheek area accommodate fuller facial structures without excess fabric pooling. Our construction methods have reduced plus-size fitting complaints by 65% compared to simply scaled-up standard patterns.

What Sizing and Validation Processes Ensure Proper Fit?

Developing effective plus-size masks requires robust sizing systems and validation protocols.

How should plus-size sizing be categorized?

Multi-dimensional sizing systems that account for both facial width and depth create more accurate fitting options than single-dimension approaches. Our system uses three key measurements: cheek-to-cheek width, nose-to-chin length, and jawline circumference to place individuals in appropriate size categories. This approach has improved first-time fit success from 45% to 85% in plus-size demographic testing.

What validation methods confirm proper fit?

Diverse fit testing panels representing the full spectrum of plus-size facial structures provide real-world validation beyond theoretical measurements. These panels should include various face shapes (round, oval, square) within the plus-size range to ensure universal accommodation. Our validation process involves 50+ testers across the size range, with iterative improvements based on their feedback.

What Business Considerations Impact Plus-Size Mask Sourcing?

Understanding the commercial aspects of plus-size mask production helps develop viable sourcing strategies.

How do MOQs compare for plus-size versus standard masks?

Similar minimum order quantities typically apply to plus-size masks, though fabric consumption is 15-25% higher due to larger pattern pieces. Manufacturers familiar with plus-size production understand these material differences and price accordingly. Our plus-size mask MOQs start at 500 pieces per size, matching our standard mask requirements despite the increased material usage.

What about inventory management for multiple sizes?

Strategic size assortment planning based on demographic data prevents overstocking less common sizes while ensuring availability across the range. Our sales data shows approximately 40% of plus-size mask sales occur in the middle (X-Large) size, with 30% each in Large and XX-Large, informing our production planning and inventory allocation.

Conclusion

Sourcing custom-fit fabric masks for plus-size markets requires specialized expertise in pattern engineering, size-specific construction methods, and validation processes that address the unique fitting challenges of larger facial structures. Success in this underserved market comes from recognizing that plus-size consumers need genuinely redesigned products rather than scaled-up versions of standard masks.

The investment in proper plus-size mask development delivers returns through access to a loyal consumer segment that actively seeks products designed for their specific needs. As awareness of fit diversity grows, companies that proactively address plus-size requirements position themselves as inclusive brands while capturing a valuable market opportunity.

Ready to develop custom-fit fabric masks for the plus-size market? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our plus-size mask expertise and how we can help you create products that genuinely fit and flatter larger facial features. We'll share our sizing system and fit validation approach to ensure your plus-size mask line delivers both comfort and protection.