As mask technology evolves from basic filtration to comprehensive environmental monitoring, integrating atmospheric (barometric) pressure sensors unlocks critical new functionalities. These sensors enable altitude tracking, weather change prediction, and advanced breathing diagnostics by detecting minute pressure changes. For manufacturers developing masks for aviation, high-altitude sports, or health monitoring, sourcing reliable pressure sensing systems that function in the challenging environment of a wearable is a complex but valuable endeavor.

Masks with integrated atmospheric pressure sensors incorporate micro-electromechanical systems (MEMS) barometers that measure absolute air pressure with high precision, enabling features like real-time altitude tracking for aviation safety, early storm warning for outdoor workers, and the calculation of breathing work (effort) by analyzing the small pressure oscillations created during inhalation and exhalation within the mask cavity. Successful sourcing requires navigating the trade-offs between sensor accuracy, power consumption, size, and resilience to moisture and temperature fluctuations inherent to breathing.

The global MEMS pressure sensor market is projected to reach $4.2 billion by 2028, with wearable health and industrial safety being key growth drivers. Unlike smartphones that use barometers for step counting and GPS enhancement, masks present a unique challenge: the sensor is exposed to a warm, humid, and dynamic microclimate. A pressure sensor for a mask must distinguish between the subtle pressure drop caused by taking a breath at 3,000 meters and the significant pressure drop caused by an approaching storm, all while being subjected to condensation. Let's explore how to source these sophisticated components and systems effectively.

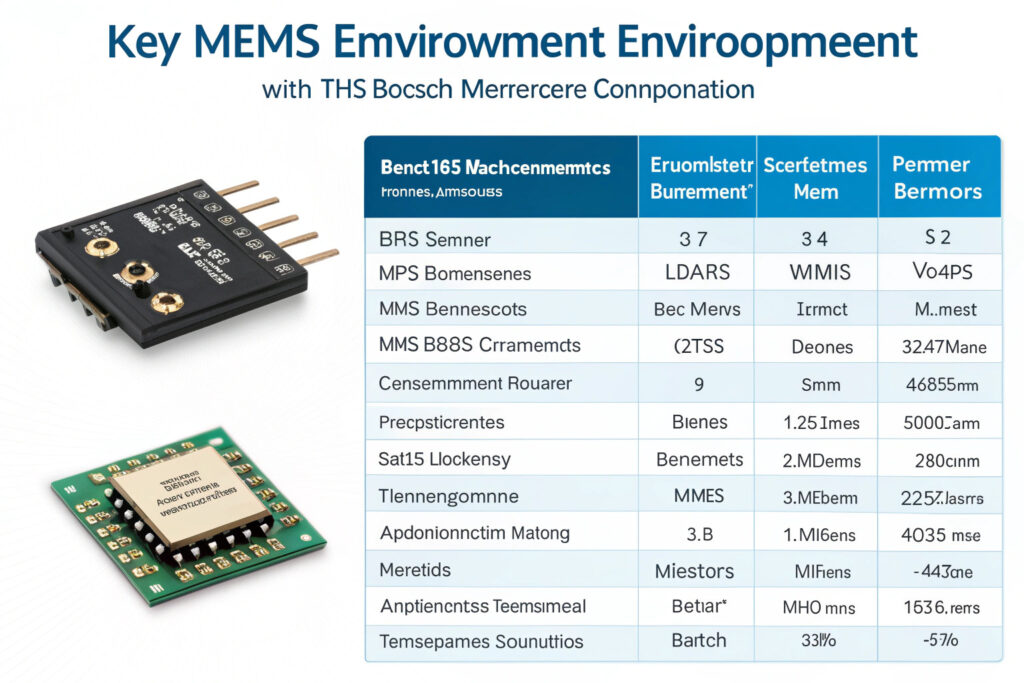

What MEMS Barometer Specifications Are Critical for Mask Use?

Not all MEMS barometers are created equal. Selecting the right sensor begins with understanding key performance parameters and how they relate to the mask's intended application.

How Does Absolute Accuracy Impact Altitude and Breathing Analysis?

Absolute accuracy is the sensor's error relative to a known pressure standard, typically expressed in hectopascals (hPa) or pascals (Pa). For altitude tracking in aviation or mountaineering masks, high absolute accuracy is critical. A typical specification might be ±0.5 hPa (which translates to roughly ±4 meters of altitude error at sea level). For breathing effort analysis, relative accuracy and low-noise performance are more important than absolute accuracy, as the system measures the small, repetitive pressure differential (often less than 0.1 hPa) inside the mask versus outside. Leading sensors like the Bosch BMP581 offer an absolute accuracy of ±0.08 hPa and ultra-low noise of 0.08 Pa, making them suitable for both applications. When sourcing, clarify whether the stated accuracy includes temperature compensation over your intended operating range.

Why is Full-Scale Range and Overpressure Tolerance Important?

The full-scale range defines the minimum and maximum pressures the sensor can measure. A mask used from deep mines to high-altitude flights needs a wide range (e.g., 300 hPa to 1250 hPa). Furthermore, overpressure tolerance is crucial. A mask may be subjected to sudden pressure spikes—a cough, sneeze, or the mask being dropped onto a surface. A sensor with low overpressure tolerance (e.g., 2x operating range) can be damaged. Industrial-grade sensors, such as the TE Connectivity MS5837-30BA, often offer tolerance up to 10 times the operating pressure. Always specify the required overpressure tolerance based on worst-case user scenarios.

How to Manage the Sensor's Exposure to the Breathing Microclimate?

The interior of a mask is a harsh environment for electronics: near-100% relative humidity, temperatures up to 36°C, and potential exposure to saliva droplets. Protecting the sensor is a primary integration challenge.

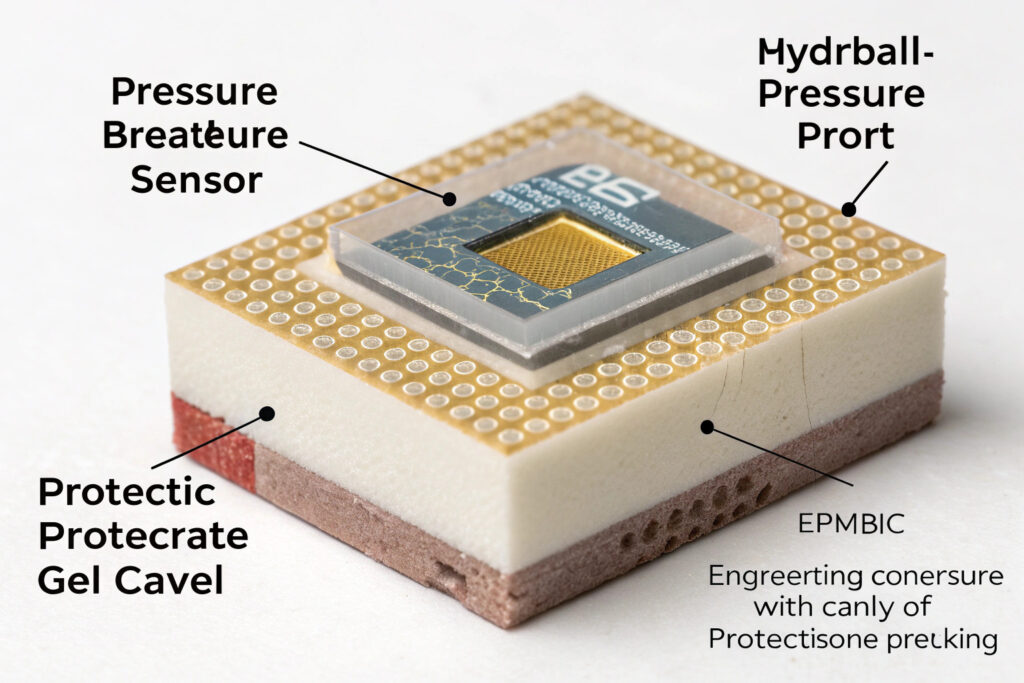

What Protective Barriers Prevent Condensation and Contamination?

A hydrophobic, breathable membrane is the first line of defense. Materials like expanded Polytetrafluoroethylene (ePTFE), used in premium outdoor gear, allow air molecules (and thus pressure waves) to pass freely but block liquid water and particulates. This membrane covers a tiny pressure equalization port that leads to the sensor cavity. Behind this, the sensor itself should be in a pre-packaged format that provides its own seal. The best practice is to use sensors in a cavity-landed ceramic package with a gel-filled port, rather than bare die, for additional protection. The entire assembly must be tested for waterproofness (e.g., IP67) while maintaining pressure response time under 1 second.

How Does Venting Design Affect Response Time and Accuracy?

The vent path design—the tiny channel or labyrinth that connects the outside environment to the sensor—is critical. It must be designed to prevent clogging by dust or fabric lint while allowing rapid pressure equalization. A longer, narrower vent increases response time but offers better protection. Computational Fluid Dynamics (CFD) simulations can optimize this trade-off. Furthermore, the vent path must be designed to minimize pressure drop across it during rapid breathing; any significant drop would corrupt the breathing effort measurement. Suppliers with experience in wearable medical devices (like spirometers) will have validated vent designs for dynamic pressure measurement.

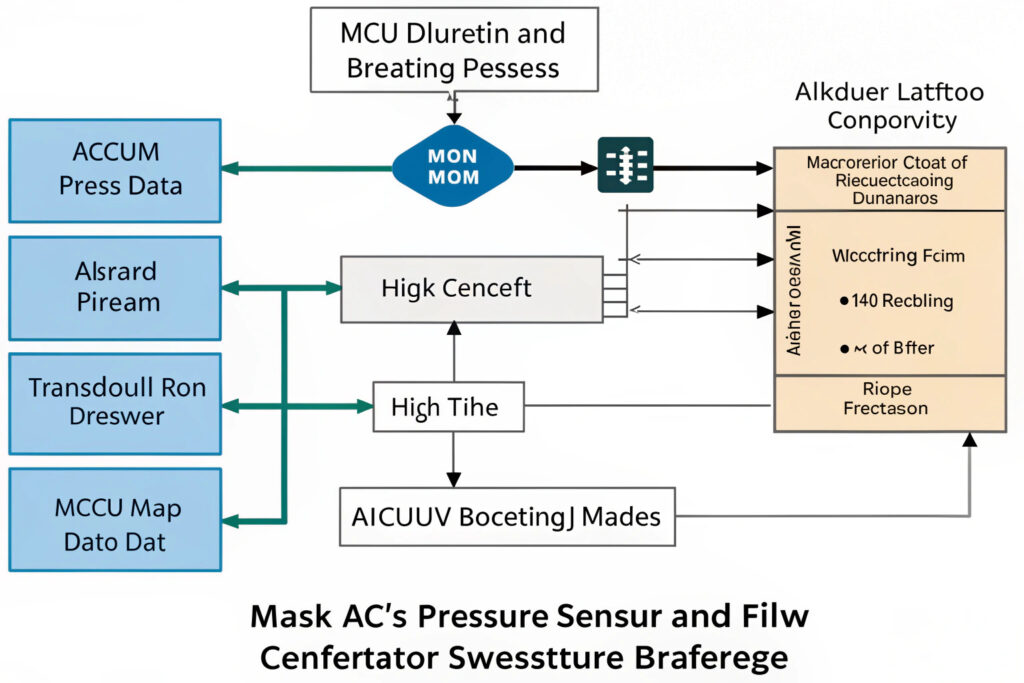

What Data Processing Architectures Are Needed for Different Applications?

The raw pressure data from the sensor is just a number. Extracting meaningful insights—altitude, breathing rate, inspiratory effort—requires specific processing algorithms, which may reside on a local microcontroller or be processed in the cloud.

How is Breathing Effort Calculated On-Device?

Calculating breathing effort (work of breathing) requires high-frequency sampling (≥50 Hz) to capture the pressure waveform. An onboard microcontroller with a digital signal processing (DSP) capability runs a real-time algorithm that:

- Filters the signal to remove noise from motion and heart beats.

- Identifies each breath cycle (inhalation start, peak, exhalation).

- Integrates the area under the pressure-time curve for the inhalation phase, which is proportional to the muscular effort required.

This processed metric can be used locally to trigger alerts if breathing effort becomes excessive (a sign of filter clogging or respiratory distress). Sourcing a complete module with this processing baked in, from suppliers like Analog Devices with their health sensor platforms, can accelerate development.

How Are Altitude and Weather Trends Derived?

For altitude and weather, lower-frequency sampling (1 Hz) is sufficient. The absolute pressure reading is converted to altitude using the International Standard Atmosphere (ISA) model. To predict short-term weather changes (e.g., a storm causing pressure to fall), the device tracks the rate of pressure change over time (the pressure tendency). This calculation is often done in a connected smartphone app to conserve mask battery life. The app can correlate pressure trends with GPS location for highly accurate altitude correction and weather alerts.

How to Verify Performance and Reliability in Real-World Conditions?

Lab specifications are one thing; performance on a sweaty face during physical activity is another. Rigorous, application-specific testing is non-negotiable.

What Validation Testing Against Gold Standards is Required?

For breathing metrics, the mask system must be validated against a clinical-grade pneumotachograph or spirometer. This involves simultaneous recording during a protocol that includes resting, talking, and graded exercise. Correlation coefficients (e.g., Pearson's r > 0.95) and Bland-Altman plots are used to prove accuracy. For altitude, validation requires a controlled pressure chamber or real-world testing with a certified altimeter. Suppliers should provide not just sensor datasheets, but application notes and validation reports for mask or wearable use cases. Evidence of testing per relevant sections of ISO 80601-2-74 (for respiratory equipment) is a strong indicator of a serious supplier.

How is Long-Term Drift and Calibration Managed?

All pressure sensors experience some long-term drift. The sourcing strategy must include a calibration plan. Options include:

- Factory Calibration: Each sensor is calibrated at two known pressures and temperatures, with coefficients stored in its memory. This is standard for good MEMS barometers.

- In-Field Calibration: The system can periodically auto-calibrate when it detects the user is at a known, stable altitude (e.g., via GPS at a known location). This requires system-level intelligence.

When sourcing, understand the recommended re-calibration interval and whether the supplier offers end-of-line calibration services for your assembled product to ensure final performance.

Conclusion

Sourcing masks with integrated atmospheric pressure sensors is a multidisciplinary challenge that spans precision MEMS selection, robust mechanical packaging for harsh environments, specialized algorithm development, and rigorous human-factors validation. The most successful outcomes come from partnering with sensor suppliers who understand wearable applications and from investing in thorough environmental sealing and testing. When executed well, the integration adds profound value—transforming a mask into a device that can warn a pilot of rapid ascent, alert a hiker to deteriorating weather, or monitor a patient's respiratory function, all from the simple, fundamental measurement of air pressure.

Ready to develop masks with intelligent atmospheric pressure sensing capabilities? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Our engineering team has experience integrating environmental sensors into wearable formats and can guide you from component selection to validated, manufacturable product.