The integration of bone conduction microphone technology into fabric masks represents a significant advancement in wearable communication devices, particularly valuable for healthcare professionals, customer service staff, and anyone needing clear communication while masked. Sourcing these specialized masks requires understanding both the textile manufacturing and electronic component integration aspects of production.

To source masks with integrated bone conduction microphone patches, identify manufacturers with expertise in technical textile-electronics integration, verify their component sourcing for quality microphones, ensure proper washability and durability testing, and confirm compliance with relevant electronic device regulations. The most reliable suppliers typically have experience in smart textile manufacturing or partnerships with electronics specialists.

Bone conduction technology works by detecting vibrations through the facial bones rather than capturing sound through air, making it particularly effective in noisy environments and when wearing masks that muffle traditional microphones. Successfully sourcing these advanced masks requires navigating the intersection of textile manufacturing, electronics integration, and quality assurance. Let's examine the specific sourcing considerations and supplier qualifications needed for these specialized products.

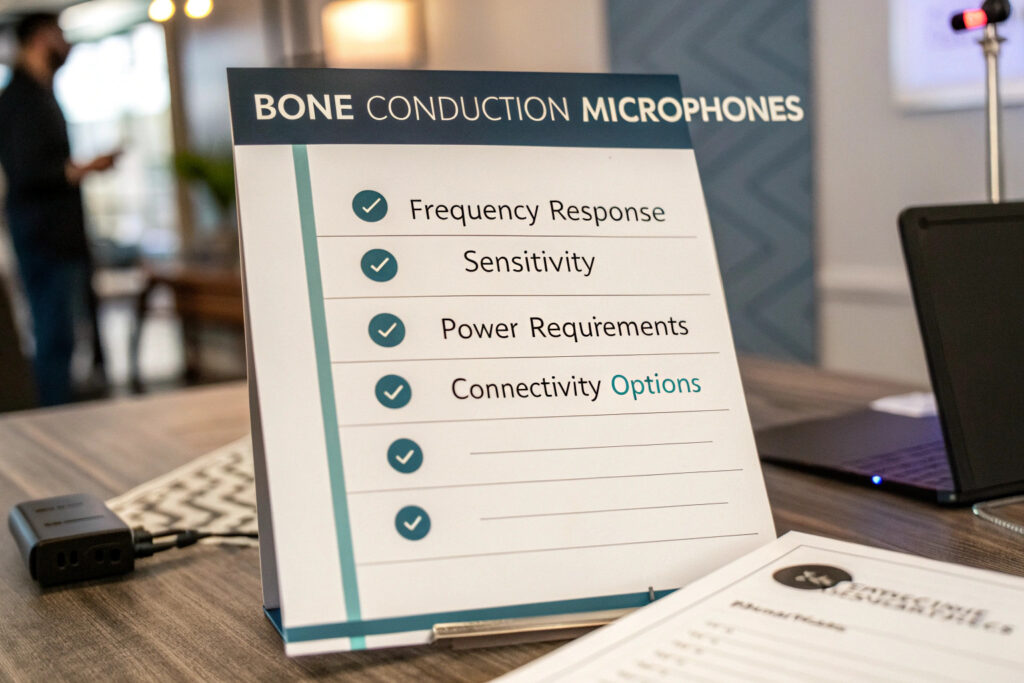

What Technical Specifications Should You Verify?

Understanding the critical technical aspects ensures you source masks that deliver both clear audio and reliable performance.

What microphone performance metrics matter most?

Frequency response optimized for speech (300-3400 Hz) ensures voice transmission clarity rather than full-range audio capture. Sensitivity specifications (typically -26±3dB) determine how effectively the microphone detects vocal vibrations. Signal-to-noise ratio (≥60dB preferred) indicates how well the system distinguishes speech from background noise. Reputable manufacturers provide test reports from audio laboratories verifying these specifications. Our quality standards require third-party audio testing showing ≥85% speech intelligibility in 70dB background noise.

How does power and connectivity impact functionality?

Battery life and charging systems vary significantly between designs—disposable battery versions (50-100 hours) versus rechargeable systems (8-16 hours per charge). Connectivity options include Bluetooth integration (compatible with communication systems) or wired connections (more reliable but less convenient). Our most popular design uses Bluetooth 5.0 with 10-hour battery life and quick-charge capability (2 hours for full charge), meeting the needs of most professional users.

What Manufacturing Capabilities Are Essential?

Identifying manufacturers with the right technical expertise and production capabilities is crucial for successful sourcing.

What electronics integration expertise is required?

Manufacturers need experience with e-textile production including conductive thread/yarn applications, flexible circuit board integration, and washable electronic component encapsulation. The best suppliers have specific departments or partners specializing in textile-electronics integration rather than treating electronics as an afterthought. Our manufacturing process involves specialized teams for textile production, electronics assembly, and final integration testing.

How important is washability engineering?

Waterproof encapsulation of electronic components is essential for masks that require regular cleaning. This includes conformal coating of circuit boards, sealed connectors, and wash-testing protocols. Manufacturers should provide evidence of durability through multiple wash cycles (typically 20-50 cycles minimum). Our wash-testing protocol verifies functionality after 50 industrial washing cycles at 60°C, ensuring professional-grade durability.

What Component Sourcing and Quality Assurance Matters?

The quality of individual components directly impacts the final product's performance and reliability.

How do you verify microphone component quality?

Supplier certifications and testing documentation for bone conduction transducers should verify performance consistency and durability. Look for components from established manufacturers like Knowles, Sonion, or similar quality suppliers rather than uncertified generic components. Our component specification requires CE/RoHS certification and batch testing documentation for all electronic components.

What about battery safety and certification?

Battery safety certifications (UL, CE, IEC standards) are crucial for products worn near the face. Both disposable and rechargeable battery systems require proper testing and documentation. Our power systems use certified Li-polymer batteries with protection circuits that prevent overcharging and overheating, with full documentation available for client review.

What Regulatory Compliance Considerations Apply?

Masks with integrated electronics may fall under multiple regulatory frameworks depending on their classification.

When do electronic device regulations apply?

CE marking for electronic devices may be required under RED (Radio Equipment Directive) for Bluetooth models or EMC Directive for all electronic versions. FCC certification is needed for the US market. Manufacturers should have experience with these certifications and provide documentation. Our compliance team manages full certification processes for all target markets, typically requiring 8-12 weeks for new designs.

What about medical device considerations?

If marketed for healthcare applications, medical device regulations (FDA Class I or II, EU MDR) may apply depending on intended use claims. Even without explicit medical claims, healthcare usage may trigger regulatory scrutiny. We recommend clear intended use statements and, when necessary, pursuing appropriate medical device certifications for healthcare-targeted products.

What Design Considerations Impact User Experience?

Thoughtful design elements significantly impact both comfort and functionality in daily use.

How does component placement affect performance?

Optimal transducer positioning typically along the jawline or cheekbone where vocal vibrations transmit most effectively. The design must maintain skin contact in these areas while remaining comfortable during extended wear. Our development process includes vocal vibration mapping to identify ideal placement for different facial structures.

What about mask structure and electronics integration?

Maintaining mask functionality while incorporating electronics requires careful design. The mask must still provide adequate filtration, comfortable fit, and breathability despite added components. Our designs use low-profile components positioned away from the breathing zone, maintaining the mask's primary protective function while adding communication capabilities.

What Are the Cost and Minimum Order Considerations?

Understanding the economic factors helps plan appropriate sourcing strategies for these specialized products.

What cost factors should you anticipate?

Significant cost premiums of 300-500% compared to standard fabric masks reflect the added electronic components, specialized manufacturing processes, and certification requirements. A basic fabric mask costing $1.50-2.50 might increase to $8-15 with integrated bone conduction technology. Our pricing transparency clearly breaks down material costs, electronics, assembly, and certification expenses.

What are typical minimum order quantities?

Higher MOQs typically range from 1,000-5,000 units due to the specialized nature of production and component minimums. Electronics manufacturers often have significant minimums for custom components, while the assembly process requires specialized setup. We offer tiered MOQs starting at 2,000 units for standard designs and 5,000 units for fully custom developments.

Conclusion

Sourcing masks with integrated bone conduction microphone patches requires identifying manufacturers with specific expertise in technical textile-electronics integration, verifying their component quality and manufacturing processes, ensuring proper durability and washability, and confirming regulatory compliance for the target markets. The most successful sourcing relationships involve partners who understand both the textile and electronics aspects rather than attempting to combine these specialties through separate suppliers.

While the complexity and cost are significantly higher than standard fabric masks, the value proposition for specific user groups—healthcare, customer service, industrial, and security professionals—often justifies the investment through improved communication capability and productivity.

Ready to explore sourcing masks with integrated bone conduction technology? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our technical capabilities and component partnerships. We'll help you navigate the technical requirements and regulatory landscape to develop communication-enhanced masks that meet your specific needs.