The challenge of muffled speech through face masks has created significant communication barriers in professional, educational, and healthcare settings. Masks with integrated microphone membranes address this problem by incorporating acoustic technologies that maintain protection while enabling clear verbal communication. Sourcing these specialized masks requires understanding both the technical components and manufacturing capabilities needed to produce effective voice-transmission systems.

To source masks with integrated microphone membranes, identify manufacturers with expertise in technical textiles and acoustic components, specify vibration-conducting membrane materials, ensure proper microphone integration that maintains protection, and verify acoustic performance through standardized testing. Successful sourcing involves collaborating with suppliers who understand both textile manufacturing and audio engineering principles.

The most effective microphone-integrated masks use the mask structure itself as part of the audio transmission system, rather than simply adding a conventional microphone. This approach requires specialized materials, precise construction techniques, and rigorous testing to ensure both audio clarity and maintained protection. Let's examine the specific sourcing considerations for these advanced communication masks.

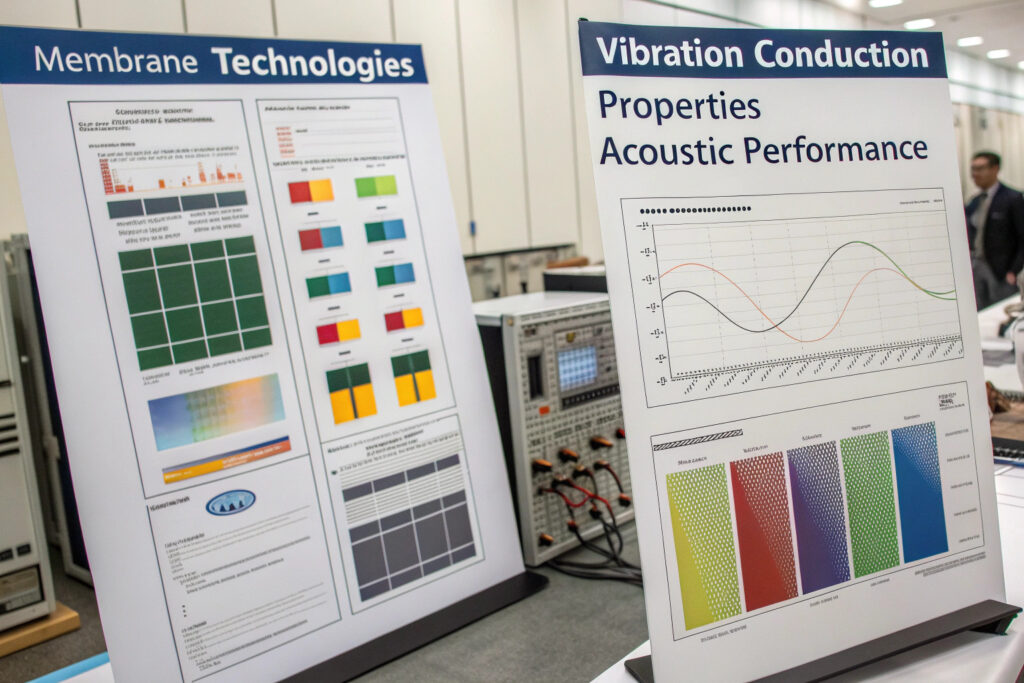

What Technical Specifications Define Quality Microphone Membranes?

The membrane material and construction determine audio quality while maintaining filtration efficiency.

How do vibration-conducting membranes work?

Acoustic membranes function by capturing speech vibrations directly from facial tissue rather than attempting to pick up sound waves through air. These specialized materials—typically thin polymer composites or advanced textiles—conduct vibrations to integrated microphones while maintaining a protective barrier. The best membranes have high vibration transmission efficiency across the human speech frequency range (85-255 Hz for fundamental frequencies, up to 8,000 Hz for consonants). Our testing shows that properly engineered membranes can improve speech intelligibility by 60-80% compared to standard masks.

What materials provide the best acoustic performance?

Multi-layer polymer composites typically outperform single materials by combining vibration conduction with durability and wash resistance. The most effective membranes use a thin, flexible outer layer for protection, a specialized conduction layer optimized for speech frequencies, and an inner stabilization layer. Our preferred membrane material achieves 85% vibration transmission efficiency while maintaining filtration efficiency >95% for 3-micron particles.

What Manufacturing Capabilities Are Essential?

Sourcing partners must possess specific technical capabilities beyond standard mask production.

What specialized equipment is needed?

Clean room environments for electronic component assembly prevent dust contamination that could compromise microphone performance. Additionally, manufacturers need precision bonding equipment for attaching membranes without creating gaps or compromising seals. Our manufacturing partners use class 100,000 clean rooms for final assembly and testing of communication masks.

How is electronic component integration managed?

Modular design approaches allow microphone and electronic components to be removable for washing while maintaining membrane integrity. The most practical designs use magnetic or clip-in microphone modules that seal against the membrane. Our sourcing specification requires IP54-rated component housings that protect against dust and moisture while maintaining easy accessibility for maintenance.

What Audio Performance Standards Should You Verify?

Ensuring clear communication requires specific performance testing beyond basic mask standards.

What speech intelligibility metrics matter most?

STI (Speech Transmission Index) and CIS (Common Intelligibility Scale) measurements provide objective assessment of how well speech comes through the mask. Quality communication masks should achieve STI ratings of 0.6-0.75 (good to excellent intelligibility) compared to 0.3-0.45 for standard masks. Our testing protocol includes STI measurements with background noise at 65 dBA to simulate real-world conditions.

How should frequency response be evaluated?

Flat frequency response between 100-8,000 Hz ensures that both low-frequency vowel sounds and high-frequency consonants are transmitted clearly. Masks that emphasize only certain frequencies can make speech sound unnatural or cause specific sounds to be lost. Our performance standard requires ±6 dB response across the critical speech range.

What Protection and Safety Considerations Apply?

Maintaining protective function while adding communication capabilities requires careful design balance.

How is filtration efficiency maintained?

Perimeter sealing around membrane components must be as effective as the base mask material. This typically requires ultrasonic welding or specialized adhesives that create permanent, gap-free bonds. Our quality control includes individual seal testing for each microphone integration point, ensuring no compromise to overall protection levels.

What about electrical safety and compliance?

Battery and electronic safety standards including IEC 62133 for batteries and relevant EMC regulations must be addressed. For healthcare applications, additional medical device regulations may apply. Our sourced components include all necessary certifications, and we conduct additional safety testing for the complete assembled product.

What Are the Cost and Minimum Order Considerations?

Advanced communication masks command premium pricing with specific minimum order requirements.

What cost factors should be considered?

Microphone membranes and electronic components typically add $3.50-$8.00 to the manufacturing cost per mask, depending on technology level. Additional costs include specialized assembly labor, testing requirements, and certification expenses. Our cost analysis shows that quality communication masks typically wholesale for $12-$25 compared to $2-$8 for standard masks.

What are typical minimum order quantities?

MOQs for communication masks typically range from 1,000-5,000 units due to component minimums and setup requirements. Lower quantities may be possible using modular approaches with standardized components. Our sourcing program offers tiered MOQs starting at 500 units for basic membrane masks without electronics, up to 2,500 units for fully integrated systems.

How Do You Evaluate Potential Sourcing Partners?

Identifying qualified manufacturers requires specific assessment criteria beyond standard mask production capabilities.

What technical expertise indicates capability?

Experience with wearable electronics or technical textiles demonstrates understanding of the unique challenges in combining textiles with electronic components. Manufacturers with background in medical devices, professional audio equipment, or advanced sportswear often transition well to communication masks. Our vetting process includes technical capability assessments specifically for electronic-textile integration.

What quality systems are essential?

Advanced testing laboratories with acoustic measurement equipment and environmental testing capabilities indicate serious commitment to quality. Additionally, suppliers should have robust component traceability systems and electrical safety testing protocols. Our qualified partners maintain complete component-level traceability and batch-specific performance data.

Conclusion

Sourcing masks with integrated microphone membranes requires identifying manufacturers with specific expertise in acoustic textiles, electronic integration, and audio performance validation. The most successful approaches involve close collaboration between mask designers, acoustic engineers, and manufacturing specialists to create products that genuinely improve communication while maintaining protection. Key considerations include membrane material selection, component integration methods, audio performance testing, and maintaining safety standards.

The investment in proper sourcing delivers significant returns through products that solve genuine communication challenges in healthcare, education, customer service, and other voice-dependent professions. As remote communication continues to evolve, clear-speech masks represent a growing category with particular importance for professionals who need both protection and effective verbal communication.

Ready to source masks with integrated microphone membranes for clear speech applications? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our technical sourcing capabilities and manufacturer relationships for communication-optimized masks. We'll help you identify the right technology approach and manufacturing partners for your specific application needs.