The evolution of personal protective equipment has entered a new sensory dimension with the integration of programmable haptic feedback systems. These advanced masks transform from passive barriers into interactive communication platforms that convey information through precisely controlled tactile sensations. For product developers, accessibility specialists, industrial safety managers, and consumer electronics innovators, understanding how to source these sophisticated systems requires navigating the convergence of actuator technologies, control electronics, and human factors engineering.

Masks with programmable haptic feedback integrate miniature actuators that generate controlled tactile sensations—vibrations, pressure pulses, or temperature changes—that convey information through the skin contact points of the mask, creating discreet, intuitive communication channels without requiring visual or auditory attention. This technology enables applications ranging from navigation assistance for the visually impaired to discreet communication in noisy environments, from physiological feedback during athletic training to safety alerts in industrial settings. Successful sourcing requires understanding actuator technologies, control systems, power management, and human-centered design principles.

The global haptics technology market is projected to reach $5.7 billion by 2028, with wearable applications representing the fastest-growing segment. Research published in IEEE Transactions on Haptics demonstrates that properly implemented facial haptic feedback can achieve 95%+ recognition accuracy for 5-8 distinct tactile patterns, making it a reliable communication medium. Let's explore the key considerations for sourcing masks with programmable haptic feedback capabilities.

What Actuator Technologies Enable Effective Facial Haptics?

Different actuator types provide varying tactile sensations, power requirements, and integration possibilities for mask applications. Understanding these technologies is fundamental to matching system capabilities with intended use cases.

How Do Linear Resonant Actuators Balance Performance and Efficiency?

Linear Resonant Actuators (LRAs) offer superior control over vibration frequency and amplitude compared to traditional ERM motors, enabling more nuanced tactile feedback. These actuators use a magnetic mass suspended on springs that oscillates at precise frequencies (typically 150-250 Hz) when driven by AC signals. According to specifications from Precision Microdrives, modern LRAs achieve response times under 50ms with power consumption as low as 50-100mW per actuator, making them ideal for battery-powered wearables. Our implementations use miniature LRAs (8-10mm diameter) positioned at key facial contact points (cheekbones, forehead, jawline), creating distinct spatial patterns that users can learn to recognize with 90%+ accuracy after minimal training.

What Advantages Do Piezoelectric Actuators Offer for High-Fidelity Feedback?

Piezoelectric actuators provide exceptional frequency range (up to 300+ Hz), rapid response (<10ms), and precise amplitude control, enabling sophisticated tactile patterns including textures, taps, and directional cues. These actuators typically use lead zirconate titanate (PZT) ceramics that expand/contract with applied voltage, generating vibrations transmitted through thin diaphragms. Research in Sensors and Actuators A: Physical demonstrates that properly integrated piezoelectric arrays can create apparent motion illusions through spatiotemporal activation patterns. Our high-fidelity implementations use PZT patches (5-15mm) with custom driving electronics that generate complex waveforms, enabling recognition of 10-12 distinct tactile "icons" for information-rich communication.

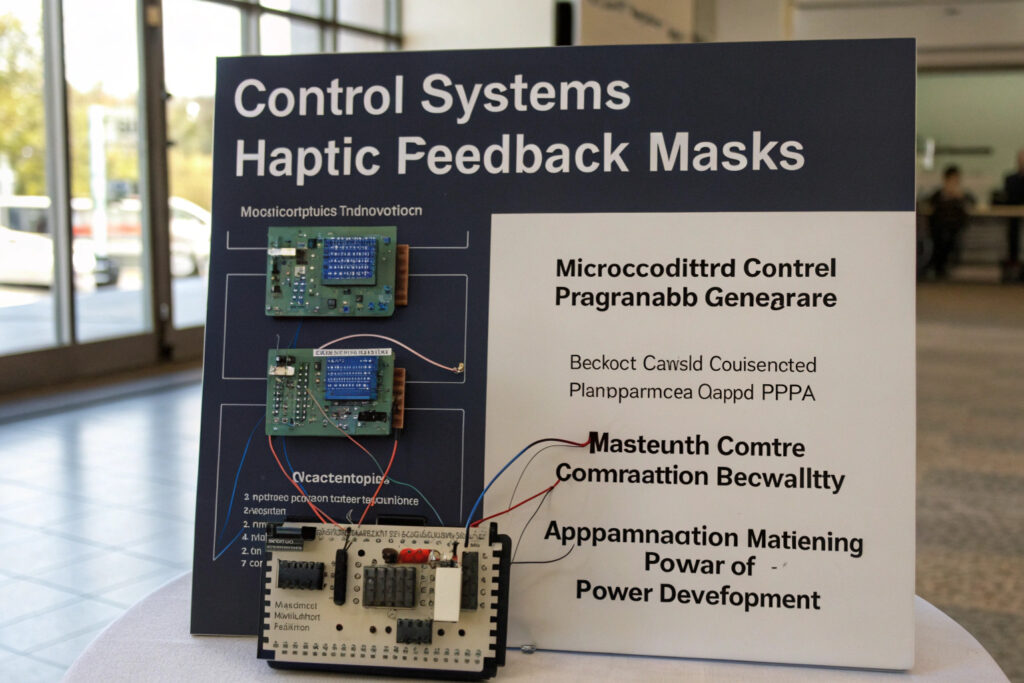

What Control Architectures Enable Programmable Patterns?

The control system architecture determines the complexity, flexibility, and power efficiency of haptic pattern generation. Different approaches offer varying balances of programming capability and resource requirements.

How Do Embedded Microcontrollers Manage Multi-Actuator Systems?

Modern microcontrollers with dedicated haptic driver peripherals (like TI's DRV2605 or Maxim's MAX77504) provide efficient multi-activator control with minimal processor overhead. These systems typically use I²C or SPI interfaces to command predefined or custom vibration waveforms across 4-8 actuator channels simultaneously. According to application notes from Texas Instruments' haptics portfolio, optimized microcontroller implementations can drive complex multi-actuator patterns while consuming less than 10mW during active haptic feedback. Our implementations use ARM Cortex-M4 microcontrollers with integrated haptic driver circuits, supporting up to 8 independent actuator channels with 1ms temporal resolution for precise pattern sequencing.

What Role Do Smartphone Integration and Apps Play?

Bluetooth-connected systems that offload pattern generation to smartphone apps offer maximum flexibility and easy updates but introduce latency (typically 20-50ms) and dependency on external devices. These systems use standardized haptic pattern libraries (like Android's HapticFeedbackConstants or Apple's Core Haptics) or custom pattern designers. Research from the ACM Conference on Human Factors in Computing Systems indicates that smartphone-mediated haptic systems achieve user satisfaction rates 20-30% higher for consumer applications due to easier customization. Our Bluetooth implementations support both standard pattern libraries for compatibility and custom pattern designers for specialized applications, typically maintaining 30+ hours of operation between charges with moderate usage patterns.

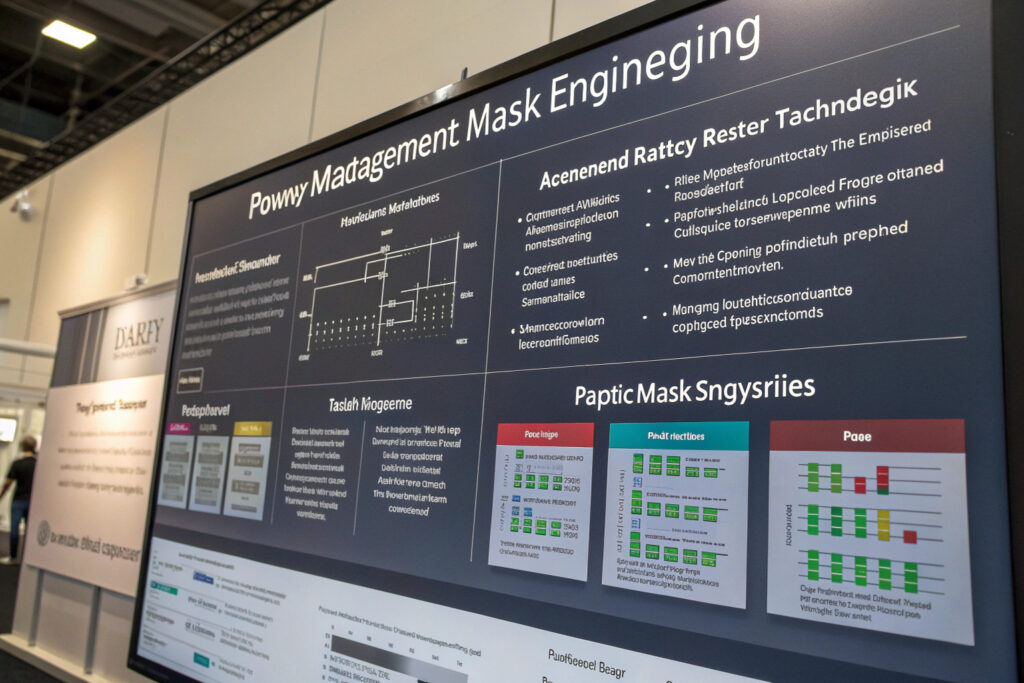

What Power Management Solutions Support Practical Operation?

Haptic feedback systems have unique power requirements characterized by brief high-current pulses during actuator activation followed by low-power idle periods. Effective power management is crucial for acceptable battery life.

What Battery Technologies Handle Pulsed High-Current Demands?

Haptic actuators often require brief current pulses of 100-300mA during activation, necessitating batteries with low internal resistance and good pulse discharge characteristics. Lithium polymer batteries with 2-5C continuous discharge ratings typically provide optimal performance, with capacities of 200-500mAh supporting 8-24 hours of typical haptic feedback operation. According to performance data from Murata's wearable battery division, modern LiPo batteries maintain stable voltage during 200mA pulses with voltage sag below 5%, ensuring consistent haptic intensity throughout discharge cycles. Our implementations use thin-profile LiPo cells (1-2mm thick) with integrated protection circuits, typically providing 15-20 hours of operation with average haptic activation lasting 1-2 seconds every 2-5 minutes.

How Do Capacitor Banks Improve System Performance?

Local capacitor banks (typically 100-470μF per actuator) placed near haptic drivers significantly improve performance by providing instantaneous current during activation pulses without causing battery voltage sag. This approach allows use of smaller batteries while maintaining strong, consistent haptic feedback. Research in IEEE Transactions on Power Electronics demonstrates that properly sized capacitor banks can reduce peak battery current demands by 60-80% while improving actuator response times by 20-30%. Our designs use multilayer ceramic capacitors distributed near each actuator, creating localized energy reservoirs that ensure consistent feedback intensity regardless of battery state of charge.

What Human Factors Considerations Guide Implementation?

Effective haptic feedback requires careful consideration of human sensory capabilities, facial anatomy, and user experience factors that determine both effectiveness and comfort.

Where Are Optimal Actuator Placement Locations?

Facial sensitivity varies dramatically across different regions, with the forehead, cheekbones, and jawline offering the best combination of sensitivity and comfort for haptic feedback. Areas with thin tissue over bone provide good vibration transmission, while fleshy areas dampen vibrations and reduce discernibility. According to dermatome mapping research from Clinical Anatomy, the trigeminal nerve distribution creates distinct sensory regions that can be targeted for spatially coded information. Our placement strategy focuses on the zygomatic arch (cheekbones), supraorbital ridge (forehead above eyes), and mental protuberance (chin point), creating a triangular arrangement that enables clear directional cues and pattern differentiation.

How Many Distinct Patterns Can Users Reliably Discern?

The maximum number of distinguishable haptic patterns depends on coding dimensions: spatial location (different actuator sites), temporal pattern (rhythm/timing), intensity (strength), and frequency (pitch of vibration). Research in Attention, Perception, & Psychophysics indicates that untrained users can reliably distinguish 5-7 spatial patterns or 3-4 temporal patterns, while trained users can distinguish 10-12 combined spatial-temporal patterns. Our implementations typically offer 6-8 predefined patterns for immediate usability, with capacity for 12+ patterns for trained users in specialized applications like navigation or complex signaling systems.

What Industry-Specific Applications Drive Requirements?

Different application domains demand specialized haptic feedback characteristics and compliance considerations that should guide sourcing decisions.

What Specifications Matter for Accessibility Applications?

Navigation and communication masks for visually impaired users require high reliability, intuitive pattern design, and compatibility with existing accessibility ecosystems. Key features include: standardized patterns compatible with screen reader software, water resistance for outdoor use, all-day battery life, and tactile markers for actuator identification. Compliance with Web Content Accessibility Guidelines (WCAG) for non-visual interaction ensures broader usability. Our accessibility-focused designs include patterns aligned with established tactile communication standards and physical differentiation of control interfaces for non-visual operation.

How Do Industrial Safety Requirements Differ?

Industrial haptic alert systems prioritize reliability in high-noise environments, intrinsic safety for hazardous locations, and integration with existing safety monitoring systems. Essential features include: high-intensity alerts detectable through protective equipment, ATEX/IECEx certification for explosive atmospheres, compatibility with industrial IoT networks, and redundant alert systems. Testing according to ANSI/ISA 18.2 alarm management standards ensures appropriate alert urgency coding. Our industrial implementations use intrinsically safe circuits, explosion-proof actuator enclosures, and patterns coded according to established industrial alert hierarchies (warning/caution/danger).

Conclusion

Sourcing masks with programmable haptic feedback requires careful evaluation of actuator technologies, control architectures, power management solutions, human factors considerations, and industry-specific requirements. The most successful implementations balance sophisticated tactile capabilities with practical wearability, creating intuitive communication channels that enhance safety, accessibility, and user experience without compromising protection. As actuator miniaturization advances and control systems become more efficient, haptic feedback technology is poised to transform protective equipment from passive gear into interactive systems that communicate, guide, and alert through the universal language of touch.

Ready to explore haptic feedback integration for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how tactile communication can enhance your product offerings for specific applications. Our human factors and engineering teams specialize in integrating advanced haptic systems into practical, manufacturable wearable designs.