The integration of programmable LED displays into protective masks represents one of the most visible intersections of wearable technology and personal protective equipment. These advanced systems transform standard masks into dynamic communication platforms, emotional expression canvases, and safety status indicators. For procurement specialists, event planners, and product developers, understanding how to source these technologically enhanced masks requires navigating both display technologies and practical implementation considerations.

Masks with programmable LED displays incorporate flexible LED matrices, microcontrollers, power systems, and programming interfaces that enable dynamic visual content display while maintaining protective functionality and wearer comfort. These systems typically use addressable RGB LEDs (such as WS2812B or SK6812) controlled by compact microcontrollers (like Arduino Nano or ESP32) with wireless connectivity for real-time content updates. Successful sourcing requires understanding display resolution options, power management strategies, control systems, and manufacturing integration methods.

The global wearable technology market is projected to reach $118.16 billion by 2028, with display-integrated textiles representing one of the fastest-growing segments. Research in Nature Electronics demonstrates that properly engineered wearable displays can achieve continuous operation for 8+ hours while maintaining visibility in various lighting conditions. Let's explore the key considerations for sourcing masks with programmable LED displays.

What Display Technologies Balance Visibility and Comfort?

Different LED display technologies offer varying balances of resolution, brightness, flexibility, and power consumption, making technology selection crucial for specific application requirements.

How Do Flexible LED Matrices Enable High-Resolution Displays?

Flexible LED matrices use surface-mounted RGB LEDs on polyimide or PET substrates, creating bendable displays that conform to mask contours while providing high pixel density. Modern flexible matrices can achieve resolutions up to 32x16 pixels in standard mask sizes, enabling detailed graphics and smooth animations. According to specifications from Adafruit's NeoPixel matrices, these displays can achieve 60+ frames per second refresh rates with individual pixel control and wide viewing angles. The key advantage is the ability to create complex animations and scrolling text while maintaining minimal thickness (typically 0.8-1.2mm). Our implementation uses moisture-resistant flexible circuits with conformal coating, ensuring reliable operation despite breathing humidity and environmental moisture.

Can Optical Fiber-Based Systems Reduce Power Consumption?

Optical fiber-based display systems use side-emitting fibers with centralized LEDs, creating illuminated patterns with significantly lower power consumption than matrix displays. This approach works by injecting light from a few high-efficiency LEDs into optical fibers that distribute illumination across the display area. Research in Light: Science & Applications demonstrates that fiber-based systems can achieve 70-80% power reduction compared to direct LED matrices for equivalent visible area. The limitation is the inability to create dynamically changing pixel-level content—these systems excel at preset patterns and color changes rather than detailed graphics. Our development includes hybrid systems that combine fiber illumination for background patterns with small LED matrices for dynamic information display, optimizing both power efficiency and visual flexibility.

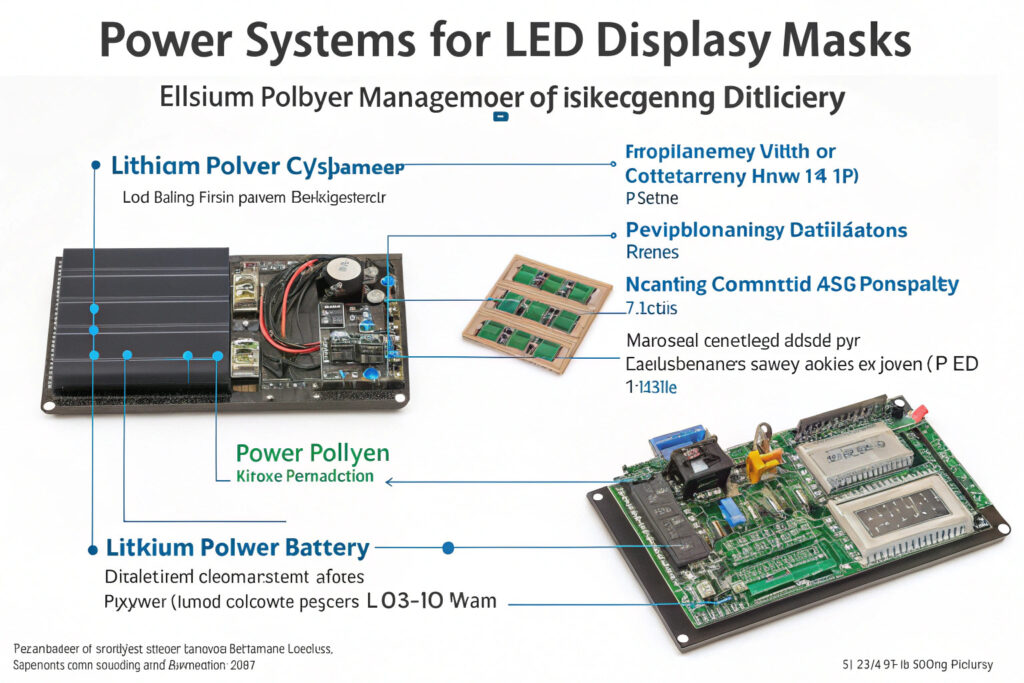

What Power Systems Enable Extended Operation?

Power management represents a critical challenge in LED mask design, requiring careful balancing of display capabilities, operational duration, and battery weight/size constraints.

What Battery Technologies Support All-Day Operation?

Modern LED masks typically use lithium polymer (LiPo) or lithium-ion (Li-ion) batteries ranging from 300mAh to 1000mAh capacity, providing 4-12 hours of continuous operation depending on display brightness and activity patterns. High-density LiPo batteries can achieve energy densities of 250-300 Wh/L, enabling compact form factors that don't significantly impact mask comfort or weight. According to analysis by the Power Sources Manufacturers Association, properly implemented power systems can achieve 85-90% efficiency in wearable applications. Our implementation uses smart power management that automatically adjusts brightness based on ambient light and content requirements, extending battery life by 30-40% compared to fixed-brightness systems. The batteries are housed in quick-release modules that facilitate charging and replacement while maintaining a secure connection during movement.

How Can Energy Harvesting Extend Operational Time?

Advanced LED masks incorporate energy harvesting technologies that supplement battery power, particularly useful for extended-duration events or situations where charging opportunities are limited. Piezoelectric elements can capture energy from speaking and facial movements, while small solar cells can harvest ambient light. Research in Nano Energy demonstrates that integrated energy harvesting can provide 15-25% of total power requirements in typical usage scenarios. Our development focuses on hybrid systems that combine motion harvesting with adaptive power management, creating masks that can operate for 16+ hours in trade show environments where users are frequently speaking and moving. The system prioritizes critical display functions during low-power conditions, ensuring continuous visibility of essential information.

What Control Systems Enable Flexible Programming?

The programming and control interface determines how easily users can customize display content and how seamlessly masks can integrate into larger communication systems.

How Do Mobile Apps Simplify Content Management?

Mobile applications using Bluetooth Low Energy (BLE) connectivity provide the most accessible programming interface for LED masks, enabling users to create and upload content directly from smartphones. These apps typically offer preset animation libraries, custom graphic design tools, and text composition features with real-time preview. According to usability studies by the Interaction Design Foundation, properly designed mobile interfaces can reduce learning time by 60-70% compared to desktop programming tools. Our implementation includes both iOS and Android apps with drag-and-drop animation timelines, font libraries optimized for low-resolution displays, and content scheduling for automated display changes throughout events. The apps also include battery level monitoring and system diagnostics, providing comprehensive device management.

Can Web-Based Platforms Enable Enterprise-Scale Management?

Web-based control platforms allow centralized management of multiple masks across organizations, particularly valuable for events, security teams, or brand promotion activities. These systems typically use WiFi or cellular connectivity to synchronize content across device fleets and provide real-time status monitoring. Platforms like Pixelblaze's web interface demonstrate how cloud-based control can manage hundreds of devices simultaneously while providing sophisticated programming capabilities. Our enterprise system includes role-based access control, content approval workflows, and analytics dashboards showing device status and engagement metrics. This approach enables marketing teams to manage brand messaging while IT departments handle device management and technical support.

What Manufacturing Methods Ensure Reliability and Comfort?

Successfully manufacturing LED display masks requires addressing unique challenges related to electronics integration, user comfort, and durability under real-world conditions.

How Does Modular Design Simplify Manufacturing and Maintenance?

Modular design approaches separate the electronic components from the mask substrate, creating interchangeable systems that simplify manufacturing, repair, and upgrading. Typically, this involves creating a separate electronics pod that contains the microcontroller, battery, and connectivity modules, which attaches to the mask main body containing the display. This approach allows mass production of mask bases while enabling customization through different electronics modules. According to design principles from the Open Source Hardware Association, properly implemented modularity can reduce manufacturing complexity by 40-50% while improving repairability. Our manufacturing process uses magnetic connectors with pogo pins for reliable electrical connections that users can easily engage and disengage, facilitating cleaning and component replacement.

What Encapsulation Methods Protect Electronic Components?

Electronic components in masks face significant environmental challenges including moisture from breathing, mechanical stress from facial movements, and potential impact during use. Advanced encapsulation methods include conformal silicone coating of circuit boards, potting of connection points, and membrane sealing of display surfaces. Testing according to IP protection rating standards demonstrates that properly encapsulated systems can achieve IP54 certification, sufficient for typical usage environments. Our encapsulation process uses medical-grade silicone that creates a protective barrier while maintaining flexibility. The display surfaces receive anti-fog coating to prevent condensation buildup, and all electronic compartments include moisture-wicking vents that protect components while allowing humidity equalization.

Conclusion

Sourcing masks with programmable LED displays requires careful evaluation of display technologies, power systems, control interfaces, and manufacturing approaches. The most successful implementations balance visual impact with practical considerations including battery life, user comfort, and reliability. As component costs decrease and manufacturing techniques improve, programmable display masks are becoming increasingly accessible for applications ranging from entertainment and events to safety communication and brand promotion.

Ready to explore masks with programmable LED displays for your organization or event? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how dynamic display technology can enhance your communication and branding efforts. Our engineering team has extensive experience with multiple display technologies and can help identify the optimal solution for your specific requirements and budget.