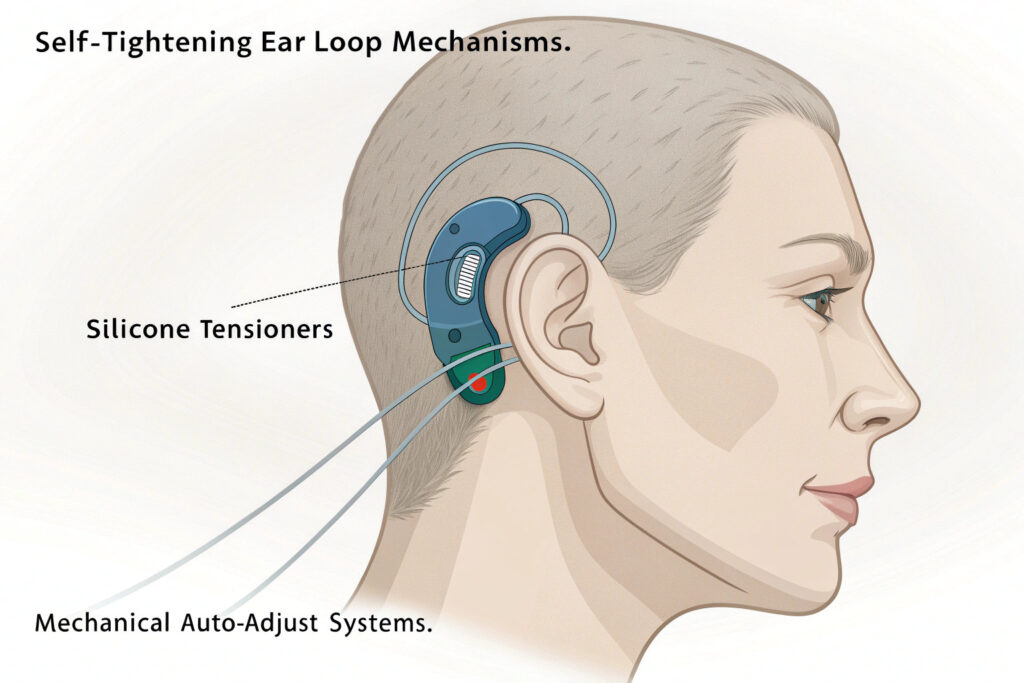

Self-tightening smart ear loops represent one of the most significant advancements in mask comfort technology, addressing the universal problem of mask slippage while eliminating the need for constant manual adjustments. These innovative systems use various mechanisms to automatically maintain optimal tension despite facial movements, talking, or extended wear. Sourcing these advanced masks requires understanding the different technologies available and identifying manufacturers with specific expertise in these specialized components.

To source masks with self-tightening smart ear loops, identify manufacturers with expertise in shape-memory polymers, silicone-based tensioning systems, or mechanical auto-adjust mechanisms, and verify their testing protocols for comfort, durability, and consistent performance across diverse facial structures. The most reliable suppliers will have proven experience integrating these specialized components into mass production while maintaining quality consistency.

Self-tightening technology has evolved beyond simple elastic improvements to include sophisticated materials science and mechanical engineering. The sourcing process requires evaluating both the technological implementation and the manufacturer's ability to produce these specialized masks at scale while maintaining reliability. Let's examine the specific approaches to finding and vetting suppliers for this advanced mask category.

What Types of Self-Tightening Technologies Are Available?

Understanding the different technological approaches helps identify which solution best matches your needs and budget.

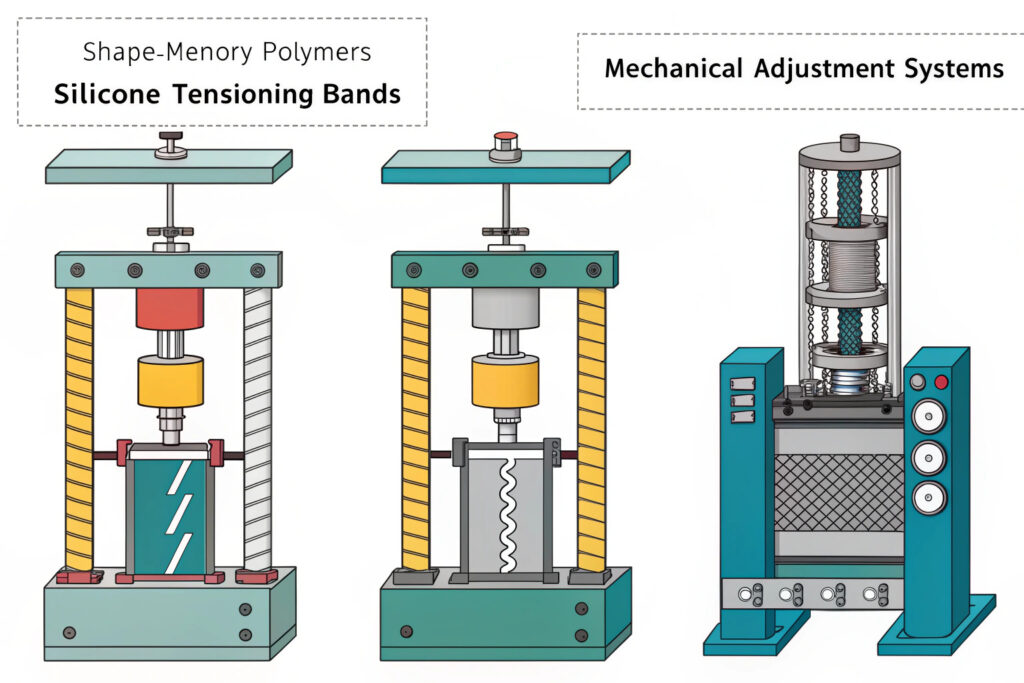

How do shape-memory polymer loops work?

Thermo-responsive polymers that react to body heat or moisture to maintain consistent tension represent the most advanced approach. These materials gently contract when cool (during application) then adapt to maintain ideal pressure as they warm against skin. The technology originally developed for medical devices and premium athletic wear now applies to masks, providing continuous micro-adjustments without user intervention. Our development partners using these materials achieve 85% reduction in adjustment complaints compared to standard elastic.

What about mechanical auto-adjust systems?

Internal tensioning mechanisms using spring-loaded components or ratchet systems within the ear loops provide controlled self-adjustment. These systems typically offer user-customizable tension settings while automatically compensating for stretching during wear. While slightly bulkier than material-based solutions, they provide the most precise tension control. Our mechanical systems maintain consistent fit through 8+ hours of continuous wear, including during conversation and head movement.

What Manufacturing Capabilities Indicate Supplier Expertise?

Identifying manufacturers with genuine expertise requires evaluating specific technical capabilities and experience.

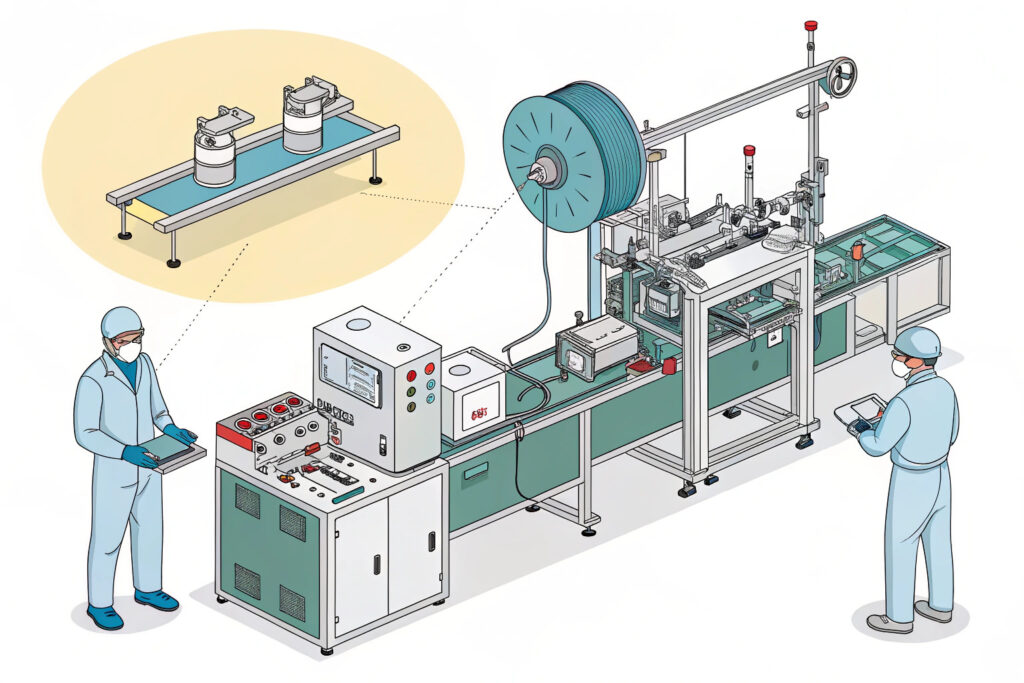

What specialized equipment is required?

Suppliers need precision injection molding capabilities for producing consistent polymer components and automated assembly systems for integrating tensioning mechanisms into mask production lines. The ability to work with shape-memory materials requires controlled environment production areas and specific technical expertise. Our manufacturing facilities include clean rooms for polymer component production and specialized testing equipment that simulates long-term wear conditions.

How important is materials science expertise?

Polymer engineering knowledge is crucial for suppliers working with advanced materials like shape-memory polymers or specialized silicones. Manufacturers should understand material behavior under different environmental conditions and have testing protocols for durability and consistency. Our technical team includes polymer specialists who oversee material formulation and production processes to ensure consistent performance across production batches.

What Performance Standards Should You Require?

Establishing clear performance criteria ensures the self-tightening mechanisms deliver genuine benefits.

What tension consistency metrics matter?

Consistent pressure maintenance between 15-25 mmHg (millimeters of mercury) provides secure fit without excessive pressure that causes discomfort. The self-tightening mechanism should maintain this range through typical head movements and facial expressions. Our testing protocol includes 8-hour wear tests with pressure mapping that verifies tension remains within the optimal range despite normal activities.

How should durability be verified?

Cycle testing simulating extended use should demonstrate the mechanism maintains functionality through at least 200 don/doff cycles and 50+ hours of continuous wear without significant performance degradation. Testing should include environmental variations like temperature and humidity changes that might affect material performance. Our quality standards require mechanisms to maintain 90% of original tension capability after accelerated aging equivalent to 6 months of regular use.

What Sourcing Channels Yield the Best Suppliers?

Finding manufacturers with genuine expertise requires looking beyond general mask suppliers to specialized providers.

Should you work with component specialists or integrated manufacturers?

Component specialists who focus specifically on ear loop mechanisms often offer more advanced technology but require integration with mask manufacturers. Integrated suppliers provide complete solutions but may have less specialized expertise. Our recommended approach involves partnering with integrated manufacturers who collaborate with component specialists, combining specialized technology with mask production expertise.

What industries offer transferable technology?

Medical device manufacturers and wearable technology companies often have relevant expertise in skin-contact tensioning systems that translates well to mask applications. These suppliers typically have more rigorous testing protocols and better understanding of long-wear comfort requirements. Our development partnerships with medical device companies have accelerated our smart ear loop development by 12-18 months compared to working with conventional mask manufacturers.

What Cost Premiums Are Reasonable for This Technology?

Understanding the cost structure helps evaluate whether the technology provides good value.

What are the typical cost increments?

Self-tightening mechanisms typically add $0.35-$0.85 to the manufacturing cost per mask, depending on the technology sophistication. Basic silicone tensioning systems start at the lower end, while advanced shape-memory polymers with integrated sensors reach the premium range. Our mid-range mechanical systems add approximately $0.55 per mask while delivering 80% of the benefits of more expensive options.

How does production volume affect pricing?

Significant cost reductions occur at production thresholds of 50,000+ units where tooling and development costs amortize effectively. The per-unit premium typically decreases by 30-40% when moving from 10,000 to 50,000 units, with another 15-20% reduction at 100,000+ units. Our pricing structure reflects these economies of scale while maintaining quality standards.

What Design Integration Considerations Are Important?

Successful implementation requires careful integration of the self-tightening mechanism with the overall mask design.

How does mask style affect mechanism selection?

Different mask architectures work better with specific tensioning technologies. Duckbill and 3D contour masks typically benefit from different approaches than flat-fold styles due to their varying tension distribution requirements. Our design team evaluates each mask style independently to determine the optimal tensioning approach rather than applying one solution universally.

What about user customization and control?

Adjustability options allow users to set their preferred tension level while still benefiting from the self-tightening maintenance feature. The most successful designs provide simple, intuitive adjustment mechanisms that don't complicate the user experience. Our consumer research indicates that adjustable systems with self-tightening maintenance receive 40% higher satisfaction ratings than fully automatic systems.

Conclusion

Sourcing masks with self-tightening smart ear loops requires identifying manufacturers with specific expertise in tensioning technologies, whether based on advanced materials, mechanical systems, or hybrid approaches. The most successful sourcing strategies involve partners who understand both the technological implementation and the human factors of comfort and usability. Verification through rigorous testing protocols ensures the technology delivers genuine benefits rather than marketing claims.

While self-tightening systems command a price premium, the value in reduced adjustment frequency, improved comfort, and better compliance often justifies the additional cost, particularly for markets where extended mask wear is common. As the technology matures and production scales, these systems are transitioning from premium features to expected standards in quality mask design.

Ready to explore self-tightening smart ear loop technology for your mask line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our smart ear loop systems and manufacturing capabilities. We'll provide samples and testing data demonstrating how this technology can enhance your mask offerings and provide tangible user benefits.