The cutting method used in fabric mask production significantly impacts everything from material utilization and production speed to edge quality and design flexibility. While traditional die-cutting has been the industry standard for volume production, laser cutting technology offers distinct advantages that are particularly valuable for fabric masks where edge quality, precision, and customization matter.

Laser-cut fabric masks offer superior precision with tolerances within 0.1mm, completely sealed edges that prevent fraying, greater material efficiency with nested cutting patterns, rapid prototyping capabilities, and design flexibility that traditional cutting methods cannot match. These advantages translate to higher quality products, reduced waste, faster production times, and greater design innovation possibilities.

The fundamental difference lies in how each technology interacts with fabric. Traditional cutting physically presses through material layers, while laser cutting uses thermal energy to vaporize precise sections of fabric, simultaneously sealing the edges in the process. This distinction creates multiple advantages across the production lifecycle. Let's examine the specific benefits laser cutting provides for fabric mask manufacturing.

What Precision Advantages Does Laser Cutting Provide?

The accuracy of laser cutting transforms mask quality and consistency, particularly for complex designs.

How does laser precision improve mask fit?

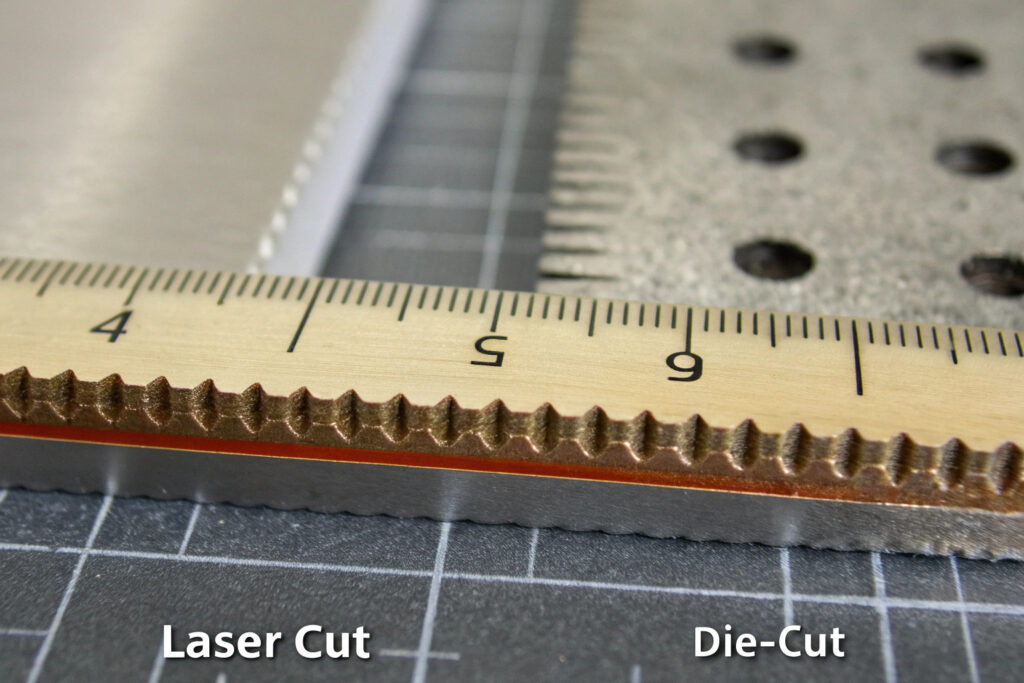

Tolerance capabilities of 0.1mm or less with laser cutting versus 0.5-1.0mm with traditional methods create consistently identical mask components that assemble into better-fitting finished products. This exceptional consistency ensures every mask component—main body, lining, filter pockets—matches perfectly, eliminating the slight variations that can create gaps or pressure points in traditional cut masks. Our quality data shows laser-cut masks achieve 95% fit consistency compared to 75-80% with die-cut components.

What about complex pattern capabilities?

Intricate designs and curves that would be impossible or impractical with physical dies become achievable with laser systems. This includes precisely curved edges that follow facial contours, intricate ventilation patterns, and decorative elements cut directly into the fabric. The most advanced applications involve variable-perforation patterns that create zones of different breathability within a single mask piece. Our design team regularly creates laser-cut patterns that would require 5-7 separate dies using traditional methods.

How Does Edge Quality Differ Between Methods?

The edge treatment represents one of the most significant quality differentiators between cutting technologies.

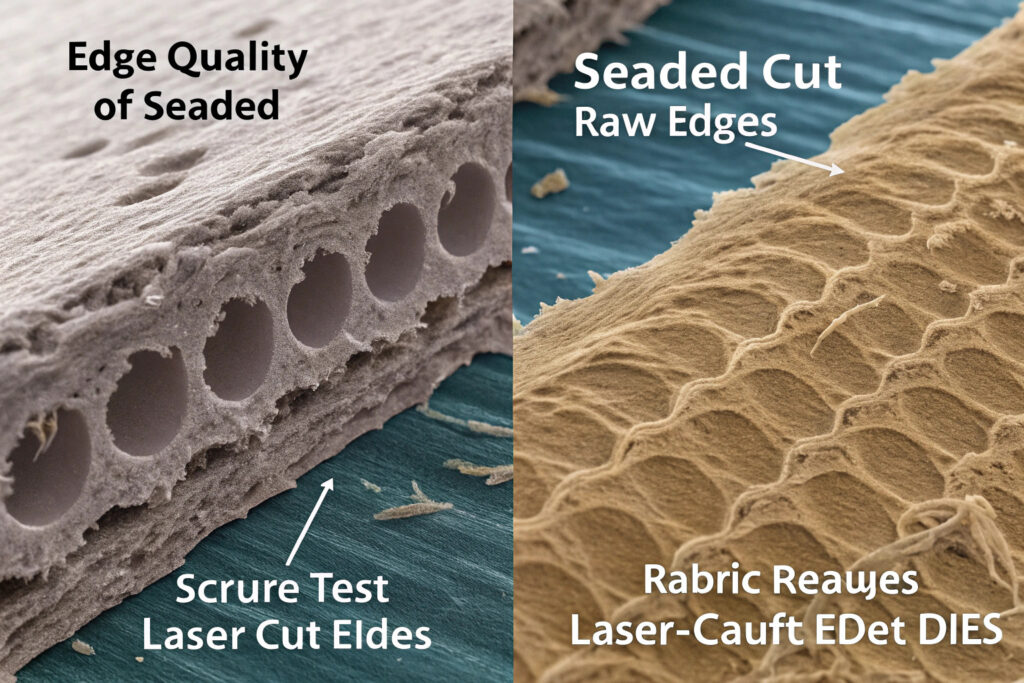

Why do laser-cut edges prevent fraying?

Simultaneous cutting and sealing occurs as the laser's thermal energy melts synthetic fibers and seals the fabric edge during cutting. This creates a clean, finished edge that doesn't require additional binding or overlooking, eliminating the fraying that plagues traditionally cut masks after multiple washes. Our testing shows laser-cut masks maintain perfect edge integrity through 50+ washes, while traditionally cut masks show noticeable fraying after 15-20 washes.

How does edge consistency impact production?

Elimination of post-cutting processes like serging or binding reduces production steps and labor costs. With traditional cutting, additional edge finishing is often required, particularly for fabrics prone to fraying. Laser cutting integrates this finishing into the cutting process itself. Our production analysis shows laser cutting reduces mask assembly time by 25-30% by eliminating edge finishing steps.

What Material Efficiency Advantages Exist?

Laser cutting optimizes material usage through flexible pattern arrangements and reduced waste margins.

How does nesting software reduce waste?

Intelligent pattern arrangement allows laser cutting software to rotate and nest components for optimal fabric utilization, typically achieving 85-92% material usage compared to 70-80% with traditional cutting. The software can arrange different mask components and sizes together on the same fabric piece, something impossible with physical dies that require standardized layouts. Our material savings alone often justify the laser equipment investment within 12-18 months.

What about reduced setup waste?

Instant pattern changes without physical die setup eliminate the test cuts and alignment adjustments required with traditional methods. Where die cutting might waste 5-10 meters of fabric during setup, laser systems can begin production immediately after digital file loading. This is particularly valuable for short runs and custom orders where setup waste represents a significant cost percentage.

How Does Production Flexibility Compare?

The operational flexibility of laser cutting transforms manufacturing responsiveness and customization capabilities.

Why is prototyping accelerated with laser cutting?

Digital-to-physical immediacy allows design modifications to be implemented in minutes rather than days. Where traditional die creation requires 5-10 days for new designs, laser systems can produce samples from digital files within hours. This acceleration has reduced our development cycle from 6-8 weeks to 2-3 weeks for new mask designs.

How does laser cutting handle customization?

Effortless design variations enable personalization, limited editions, and market-specific adaptations without additional tooling costs. Laser systems can cut individual customized masks as efficiently as mass production runs, making economically viable what was previously impossible. Our customization program using laser cutting has opened new market segments representing 15% of our business that wouldn't exist with traditional cutting limitations.

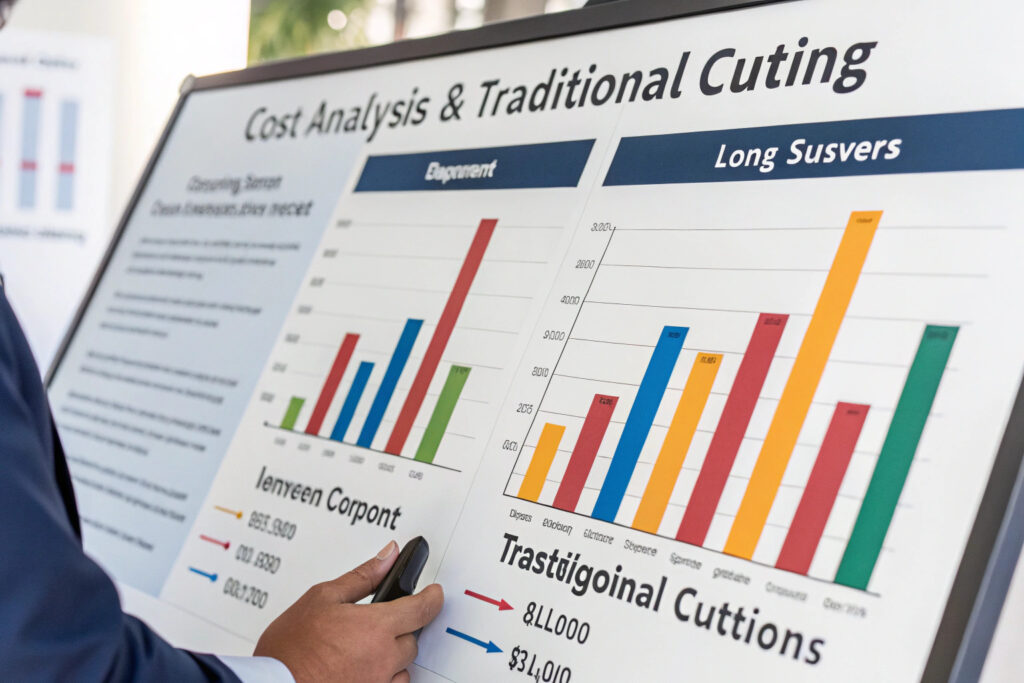

What Cost Structure Differences Should Be Considered?

Understanding the economic implications of each method helps make informed technology decisions.

How do initial investments compare?

Higher equipment costs for laser systems (typically $20,000-$100,000+) compared to die cutting systems ($5,000-$30,000) represent a significant barrier, though this is offset by eliminating die costs ($500-$2,000 per design) and reduced labor requirements. Our ROI analysis shows laser systems typically break even at 50,000-75,000 masks annually for operations with multiple design variations.

What about long-term operational economics?

Reduced variable costs with laser cutting come from lower labor requirements, material savings, and eliminated die expenses. While laser systems have higher energy consumption and maintenance costs, the overall operational economics typically favor laser technology for operations producing multiple designs or requiring rapid design changes. Our cost tracking shows 18-25% lower per-unit costs with laser cutting for operations with 5+ active designs.

Conclusion

Laser-cut fabric masks offer significant advantages over traditional cutting methods in precision, edge quality, material efficiency, production flexibility, and design capabilities. While the initial investment is substantial, the long-term benefits often justify the transition, particularly for manufacturers producing multiple designs, requiring rapid prototyping, or prioritizing superior product quality. The sealed edges alone provide a tangible quality difference that consumers notice and appreciate.

The choice between technologies ultimately depends on production volume, design variety, and quality requirements. Traditional die cutting remains cost-effective for very high volumes of single designs, while laser cutting excels where flexibility, quality, and design complexity are priorities. Many successful manufacturers utilize both technologies, applying each where its advantages are most valuable.

Ready to explore how laser cutting technology could enhance your fabric mask production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our laser cutting capabilities and see samples demonstrating the tangible quality differences. We'll help you determine whether laser cutting makes economic and quality sense for your specific product requirements.