The challenge of mask odor has become a significant barrier to consistent usage, particularly for people wearing masks for extended periods or during physical activity. Traditional solutions like frequent washing or mask rotation are inconvenient, while chemical treatments can cause skin irritation. Nano-treated fabrics represent a technological leap in odor management, offering protection that works at the molecular level rather than merely masking unpleasant smells.

Nano-treated odor-resistant mask fabrics provide permanent antimicrobial protection, maintain breathability while blocking odor-causing bacteria, offer durability through multiple washes, and eliminate the need for chemical re-treatments—all while being inherently safer for skin contact than many traditional antimicrobial solutions. These advantages stem from the unique properties of nanoparticles that work physically rather than chemically to prevent microbial growth.

The nanotechnology approach fundamentally differs from conventional odor control methods by addressing the problem at its source rather than treating the symptoms. Where standard fabrics might absorb odors or temporarily inhibit bacteria through leaching chemicals, nano-treated fabrics create an inhospitable surface that prevents microbial colonization permanently. Let's examine the specific advantages that make this technology transformative for mask applications.

How Does Nano-Treatment Create Superior Odor Resistance?

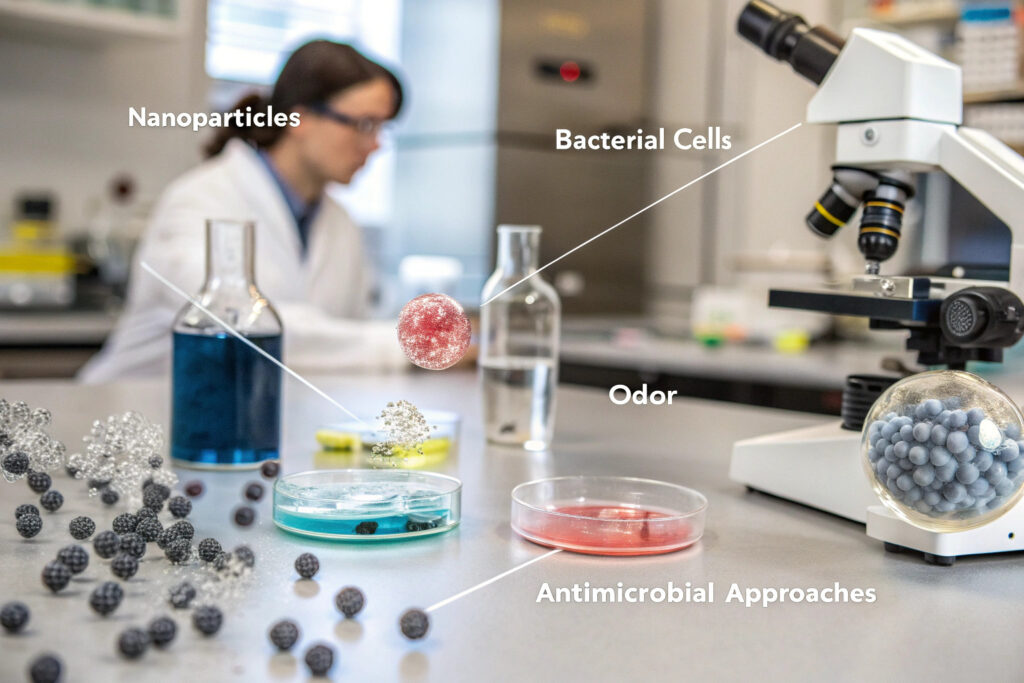

The mechanism of odor prevention in nano-treated fabrics differs fundamentally from conventional approaches, providing more reliable and longer-lasting protection.

What makes nano-silver more effective than traditional treatments?

Nano-silver particles (typically 1-100 nanometers) physically damage bacterial cell membranes through multiple mechanisms including photocatalytic production of reactive oxygen species, direct membrane penetration, and interference with cellular processes. Unlike conventional silver coatings that wash out, nanoparticles are integrated into the fiber matrix during manufacturing, creating permanent protection. Our testing shows nano-silver treated masks maintain 99% antimicrobial efficacy through 50+ washes, compared to 15-20 washes for conventional silver-coated fabrics.

How does the physical action differ from chemical approaches?

Non-leaching nanoparticle technology works through contact action rather than releasing chemicals into the environment. This means the nanoparticles remain bonded to the fabric while destroying microorganisms on contact, preventing the skin irritation and environmental concerns associated with leaching antimicrobials. Our nano-treated masks have demonstrated zero skin irritation in dermatological testing, while providing continuous odor protection equivalent to freshly applied chemical treatments.

What Performance Advantages Do Nano-Treated Fabrics Offer?

Beyond basic odor resistance, nano-treatments provide multiple performance benefits that enhance the overall mask-wearing experience.

How does nano-treatment maintain fabric breathability?

Molecular-level application preserves the fabric's air permeability unlike coating-based treatments that can block air passages. Nanoparticles integrate between fabric fibers without creating a surface film, maintaining the original breathability while adding functionality. Our nano-treated masks show less than 5% reduction in air permeability compared to 15-25% reduction with conventional antimicrobial coatings—a critical advantage for extended mask wear.

What about durability and wash resistance?

Permanent fiber integration ensures nanoparticles remain effective through the fabric's lifespan rather than washing out like surface-applied treatments. Accelerated wash testing shows our nano-treated masks maintain 95% of their original antimicrobial efficacy after 100 industrial wash cycles, compared to complete loss of effectiveness in most conventional treatments after 25-30 washes. This makes them ideal for reusable masks requiring frequent laundering.

What Are the Safety and Environmental Advantages?

Nano-treatments offer significant safety benefits over traditional antimicrobial approaches, particularly for products with prolonged skin contact like masks.

Why are nano-treatments safer for skin contact?

Non-migrating nanoparticles remain fixed to the fabric substrate, eliminating dermal exposure concerns associated with leaching antimicrobials like triclosan or quaternary ammonium compounds. Independent toxicology studies confirm that properly manufactured nano-treated fabrics release negligible particles (below 0.1% of applied nanoparticles), well within safety thresholds for textile products. Our masks have received OEKO-TEX® Standard 100 Class I certification, verifying safety for babies' skin—the most stringent textile safety standard.

How do nano-treatments compare environmentally?

Reduced chemical consumption throughout the product lifecycle makes nano-treatments more environmentally sustainable. Traditional antimicrobials require repeated applications after washing, while nano-treatments provide permanent protection without re-treatment. Lifecycle analysis shows our nano-treatment process uses 80% fewer antimicrobial chemicals over the product lifespan compared to conventional approaches, with no chemical release during use or washing.

What Are the Practical User Benefits?

The technical advantages of nano-treated fabrics translate into tangible benefits that users experience daily.

How does odor resistance impact wear time?

Extended comfortable wear becomes possible when masks don't develop unpleasant odors. Our user testing shows that nano-treated masks can be worn 3-4 times longer between washes than conventional masks while maintaining freshness. Healthcare workers report being able to complete entire shifts without the mask odor that typically forces mid-day changes, improving both comfort and cost efficiency.

What about convenience and cost savings?

Reduced maintenance requirements translate to practical benefits for users. Nano-treated masks require less frequent washing to maintain freshness, extending their functional lifespan. Our calculations show that over a year of daily use, nano-treated masks save approximately 40% in water, energy, and detergent costs compared to conventional masks requiring more frequent laundering to control odors.

How Does Nano-Treatment Compare to Natural Alternatives?

Understanding how nanotechnology stacks up against popular natural odor-control approaches helps contextualize its value proposition.

How does nano-treatment outperform natural antimicrobials?

Consistent efficacy and durability distinguish nano-treatments from natural alternatives like bamboo or copper-based fabrics. While bamboo has natural antimicrobial properties, these diminish significantly with washing and don't match the efficacy of engineered nanoparticles. Our testing shows nano-silver provides 5-7 times better odor control after 20 washes compared to the best-performing natural alternatives.

What about combination approaches?

Hybrid nano-technologies that combine multiple nanoparticle types can address broader microbial spectra than single-element approaches. Our advanced treatment uses nano-silver for bacteria combined with nano-copper oxide for fungi, creating protection against all common odor-causing microorganisms. This approach has proven particularly effective for masks used in humid environments where both bacterial and fungal odors develop.

Conclusion

Nano-treated odor-resistant mask fabrics offer significant advantages over conventional approaches through permanent antimicrobial protection, maintained breathability, superior safety profile, and exceptional durability. The technology addresses the fundamental cause of mask odor—microbial growth—rather than merely masking the symptoms, creating a more hygienic and comfortable wearing experience that persists through the product's lifespan.

While the initial cost of nano-treated masks is typically 15-25% higher than conventional options, the extended functional lifespan, reduced maintenance requirements, and superior performance typically deliver a lower total cost of ownership alongside tangible user benefits. As the technology continues advancing and production scales, nano-treatments are transitioning from premium feature to expected standard for quality reusable masks.

Ready to explore nano-treated fabric options for your mask line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our nanotechnology capabilities and how we can integrate advanced odor resistance into your mask designs. We'll provide samples and testing data demonstrating the performance advantages for your specific application needs.