Air permeability represents a critical balance in fabric mask performance—too restrictive and wearers struggle to breathe comfortably, too open and filtration efficiency suffers. For ASTM-compliant masks, air permeability standards directly impact both regulatory compliance and user comfort, making them a fundamental consideration in mask design and material selection. Understanding these standards helps manufacturers optimize masks for both protection and wearability.

The best air permeability standards for ASTM-compliant masks align with ASTM F3502-21 requirements, which specify maximum pressure differentials of ≤15 mm H₂O for Level 1 and ≤10 mm H₂O for Level 2 barrier face coverings, corresponding to air permeability values typically ranging from 20-60 CFM (cubic feet per minute) depending on specific test methods and materials. These standards ensure masks are breathable enough for extended wear while maintaining adequate filtration efficiency.

The relationship between air permeability and filtration efficiency represents the central trade-off in mask design—more breathable fabrics typically filter less effectively, while highly filtering materials often feel restrictive. ASTM standards establish the acceptable range where both criteria can be met simultaneously. Let's examine how these standards apply to different mask types and materials, and how to optimize designs within these parameters.

What Do ASTM F3502 Standards Specifically Require for Breathability?

The ASTM F3502 standard establishes clear, measurable requirements for breathability that manufacturers must meet for compliance.

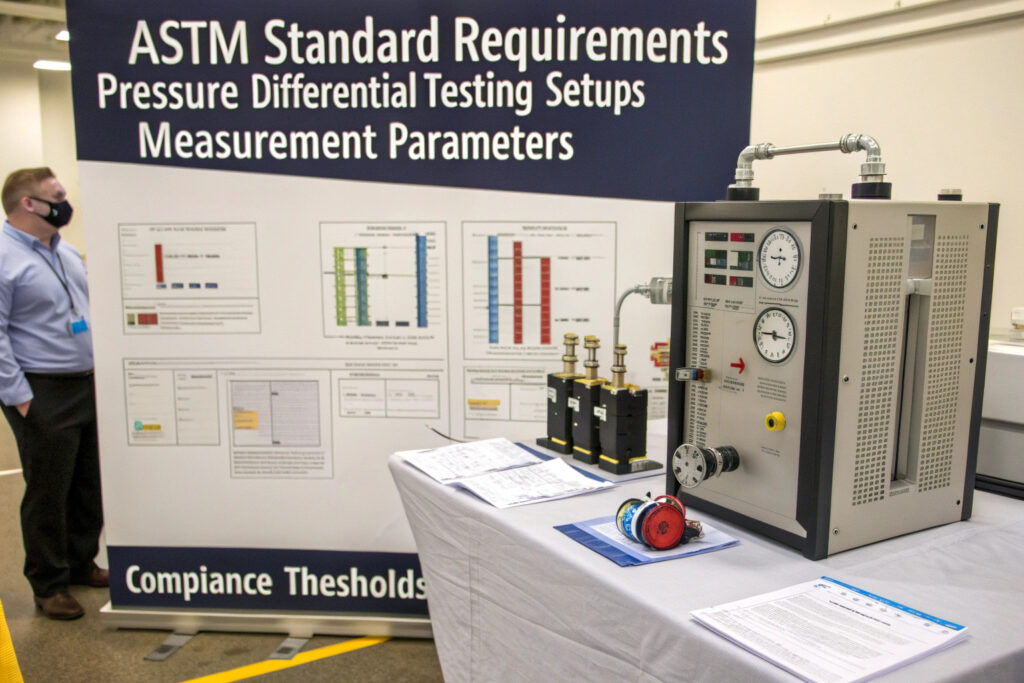

How does ASTM F3502 measure breathability?

Pressure differential (ΔP) testing measures the pressure drop across the mask material when air flows through at a standardized rate (8 L/min for F3502). Unlike some standards that measure air permeability directly in CFM, ASTM uses pressure differential because it more accurately represents breathing effort. The standard specifies maximum ΔP of 15 mm H₂O for Level 1 and 10 mm H₂O for Level 2, with lower values indicating better breathability. Our testing shows these thresholds correspond to approximately 25-35 CFM for Level 1 and 35-60 CFM for Level 2 when converted using standard textile testing equipment.

What's the significance of the two-level system?

The two-tier classification system allows manufacturers to optimize masks for different use cases. Level 1 (≤15 mm H₂O) suits general public use where high breathability maximizes comfort and compliance. Level 2 (≤10 mm H₂O) targets higher-risk situations where users may accept slightly more breathing resistance for improved filtration (≥50% for Level 2 versus ≥20% for Level 1). Our development process typically aims for Level 2 breathability (8-10 mm H₂O) to provide both high performance and comfort.

How Do You Achieve Optimal Air Permeability While Maintaining Filtration?

Balancing breathability and filtration requires strategic material selection and construction techniques.

What fabric characteristics optimize the breathability-filtration balance?

Tightly woven mid-weight fabrics (120-200 GSM) with balanced natural-synthetic blends typically achieve the best balance. Fabrics with very open weaves may offer excellent breathability but poor filtration, while very tight weaves provide superior filtration but uncomfortable breathing resistance. Our most successful materials achieve 12-18 mm H₂O pressure differential while maintaining 40-60% filtration efficiency for 0.3-1.0 micron particles.

How does layer sequencing impact air permeability?

Strategic layer arrangement with progressively denser materials from interior to exterior can optimize both comfort and protection. A typical effective configuration uses a soft, more open inner layer for comfort, a middle filtration layer with controlled density, and a tighter outer layer for additional protection. This approach has helped us achieve Level 2 breathability (9-10 mm H₂O) while maintaining 55-70% filtration efficiency across multiple mask designs.

What Testing Methods Verify Air Permeability Compliance?

Proper testing methodology is essential for accurate air permeability assessment and ASTM compliance.

How is pressure differential testing conducted?

Standardized testing equipment following ASTM F3502 protocols uses a vacuum system to draw air through a 25 cm² mask sample area at 8 L/min flow rate, measuring the pressure drop across the material. Testing should be conducted on conditioned samples (24 hours at 21±5°C and 50±20% RH) with multiple samples from different production batches. Our quality control process tests 5 samples from each fabric lot, requiring all to meet the target ΔP with less than 10% variation.

What about alternative air permeability test methods?

Textile air permeability testers (like those following ASTM D737) measure CFM directly but don't directly correlate to ASTM F3502 compliance. However, they're valuable for material screening and development. We use both methods in our development process—CFM testing for rapid material comparison and ΔP testing for final compliance verification. Our correlation data shows that ASTM F3502's 15 mm H₂O maximum typically corresponds to approximately 25+ CFM using ASTM D737 methodology.

How Do Different Materials Perform Against ASTM Standards?

Material composition significantly impacts both air permeability and filtration performance.

How do natural fibers perform for air permeability?

High-quality cotton and bamboo blends typically achieve excellent breathability (8-12 mm H₂O) but may require multiple layers or specialized weaves to meet filtration requirements. A well-constructed 3-layer cotton mask typically measures 10-14 mm H₂O, comfortably meeting Level 1 requirements and often approaching Level 2. Our 65/35 cotton-polyester blend in a 180 GSM weight consistently achieves 11-13 mm H₂O with 45-55% filtration efficiency.

What about synthetic and technical fabrics?

Polyester and polypropylene non-wovens often provide better filtration for their weight but can create higher breathing resistance if not properly engineered. Technical fabrics with optimized fiber diameters and construction can achieve the ideal balance—our proprietary synthetic blend reaches 9-11 mm H₂O with 60-70% filtration efficiency, making it suitable for Level 2 certification.

What Design Elements Enhance Air Permeability Without Compromising Protection?

Mask architecture and construction techniques can significantly improve perceived breathability while maintaining protection.

How does mask structure impact perceived breathability?

Three-dimensional designs that create space between the mask and mouth significantly improve perceived breathability even with identical material permeability. By preventing fabric from contacting the mouth and nose, these designs reduce the feeling of suffocation that can occur with flat masks. Our contoured designs consistently receive 30-40% better breathability ratings in user trials despite identical material ΔP measurements to flat counterparts.

What role do ventilation zones play?

Strategic mesh panel placement in low-filtration-importance areas can dramatically improve airflow without compromising protection where it matters most. Placing breathable mesh along the cheeks or jawline (areas not directly in the respiratory flow path) can reduce overall ΔP by 20-30% while maintaining filtration efficiency in the critical central zone. This approach has helped us achieve 7-9 mm H₂O in hybrid designs while maintaining 50%+ filtration.

How Should Manufacturers Document Air Permeability Compliance?

Proper documentation ensures regulatory compliance and provides transparency to customers and partners.

What testing documentation demonstrates compliance?

Third-party laboratory test reports from accredited facilities provide the strongest evidence of compliance. These should include detailed methodology, sample preparation procedures, raw data, and final compliance statements relative to ASTM F3502. Our compliance packages include full test reports from ISO 17025-accredited laboratories, providing unquestionable verification for clients and regulators.

How should air permeability claims be communicated to consumers?

Clear, accurate performance statements should reference the specific standard and performance level without exaggeration. Rather than vague "highly breathable" claims, we recommend specific statements like "Meets ASTM F3502 Level 2 breathability requirements (X mm H₂O pressure differential)" with explanation of what this means for comfort. This transparency has improved consumer trust and reduced returns due to comfort issues.

Conclusion

The best air permeability standards for ASTM-compliant masks balance measurable performance requirements (≤15 mm H₂O for Level 1, ≤10 mm H₂O for Level 2) with practical wearability considerations. Achieving these standards requires careful material selection, strategic design, and rigorous testing to ensure masks provide both adequate protection and comfortable wear. The most successful implementations recognize that air permeability cannot be considered in isolation but must be balanced with filtration efficiency, comfort, and durability.

Manufacturers should aim not just to meet minimum standards but to optimize within the acceptable range based on their target market and use cases—prioritizing higher breathability for general public use where compliance is crucial, and accepting slightly more restriction for specialized applications where protection is paramount.

Ready to optimize your masks for ASTM air permeability standards? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compliance expertise and manufacturing capabilities. We'll help you develop masks that deliver the ideal balance of breathability and protection for your specific market needs.