The quest for optimal, energy-efficient airflow regulation has led engineers to one of nature's most elegant solutions: the plant stoma. Biomimetic stomatal airflow systems are advanced engineering designs that replicate the structure and function of plant stomata—microscopic pores that dynamically open and close to regulate gas exchange—to create adaptive, low-power ventilation and filtration systems. For designers of smart masks, building HVAC systems, and microfluidic devices, understanding these bio-inspired systems offers a pathway to unprecedented efficiency and responsiveness.

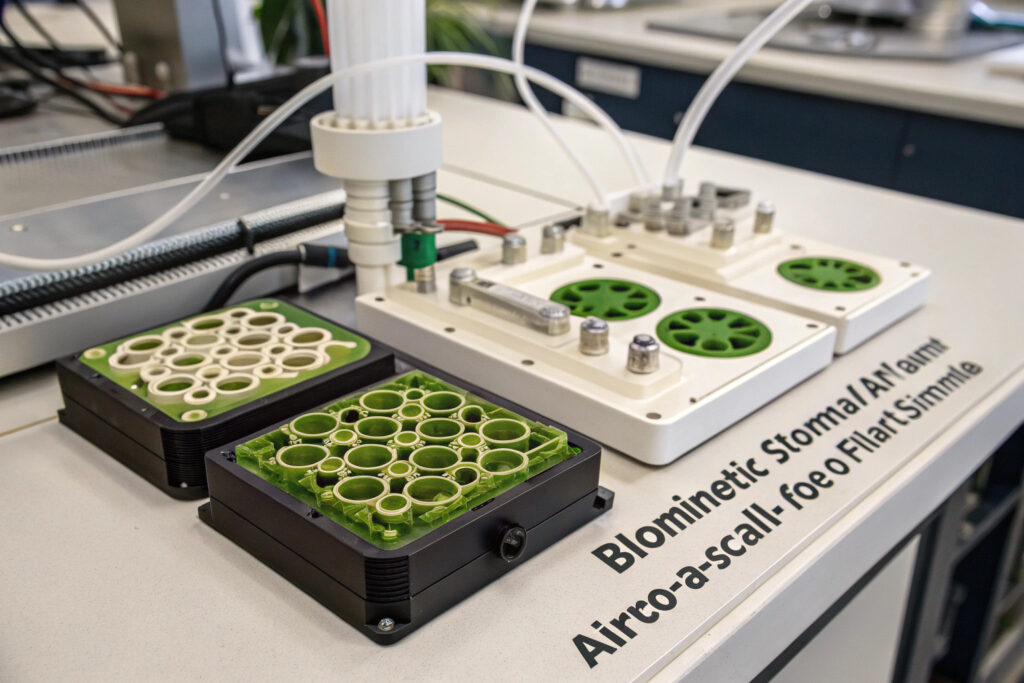

Biomimetic stomatal airflow systems are engineered micro- or nano-scale pores or valves that mimic the guard cell mechanism of plant stomata, enabling autonomous or controlled modulation of airflow based on environmental stimuli such as humidity, temperature, CO₂ concentration, or light, achieving precise gas exchange with minimal energy expenditure. These systems excel where traditional mechanical vents or fans are too bulky, power-hungry, or imprecise. The best designs capture not just the geometry but the responsive logic of biological stomata, creating systems that are self-regulating, scalable, and remarkably efficient.

Research in Nature Communications demonstrates that advanced stomatal mimics can achieve response times under 100 milliseconds with actuation energy costs approaching the thermodynamic minimum. For applications ranging from breath-responsive mask vents to smart building skins, this bio-inspired approach represents a paradigm shift. Let's examine the key principles and leading implementations of biomimetic stomatal airflow systems.

What Are the Core Biological Principles Being Mimicked?

To engineer an effective stomatal system, one must first understand the sophisticated mechanics of its natural counterpart.

How Do Guard Cells Achieve Efficient Actuation?

Plant stomata operate through the osmotic actuation of two specialized guard cells:

- Active Pumping: In response to environmental cues (like blue light or low CO₂), proton pumps in the guard cell membrane expel H⁺ ions, creating an electrochemical gradient.

- Ion & Water Influx: This gradient drives the uptake of potassium ions (K⁺) and anions. The increased solute concentration lowers the cells' water potential.

- Osmotic Turgor Pressure: Water follows by osmosis, inflating the guard cells. Due to the asymmetric, reinforced cellulose microfibril arrangement in their walls, inflation causes the cells to bend apart, opening the pore.

- Reverse Process: To close, ions are exported, water leaves, and turgor drops, allowing the cells' elasticity to close the pore.

This mechanism achieves large mechanical displacement (pore opening) from nanoscale molecular movements, with energy primarily spent on ion transport rather than moving mass—a principle of extreme efficiency.

What Environmental Triggers Are Most Relevant for Engineering?

Natural stomata respond to a complex interplay of signals: light, atmospheric CO₂, humidity (VPD - Vapor Pressure Deficit), and plant hormones. For engineered systems, the most directly useful triggers are:

- Humidity: Perfect for masks or clothing, where high exhaled humidity could trigger vent opening.

- CO₂ Concentration: Ideal for indoor air quality management in rooms or helmets.

- Light: Useful for building façades or solar-powered devices.

The "best" system selects a trigger that aligns perfectly with its operational goal and environment.

What Are the Leading Material and Actuation Strategies?

Engineers have developed various approaches to replicate the stomatal function, ranging from hydrogel-based systems to sophisticated micro-electromechanical systems (MEMS).

How Do Responsive Hydrogel Systems Work?

Hydrogels—3D polymer networks that absorb water—are the most direct analog to guard cells.

- Mechanism: A hydrogel sheet is fabricated with precisely cut pores. As ambient humidity rises, the hydrogel absorbs water vapor and swells. This swelling reduces the pore's effective diameter or even closes it completely. When humidity drops, the hydrogel deswells, reopening the pore.

- Advantages: Fully passive, no power required; simple fabrication; excellent for humidity-triggered applications.

- Limitations: Response can be slower than biological stomata (seconds to minutes); cycling durability can be an issue; control is primarily single-stimulus.

Research from the Max Planck Institute on poly(N-isopropylacrylamide) (PNIPAM) hydrogels shows they can create effective "smart" gating membranes for moisture management.

What Are Bilayer and Multi-Material Actuators?

Inspired by the asymmetric wall of guard cells, these actuators use two bonded layers with different responses to a stimulus.

- Mechanism: For a humidity-responsive version, one layer might be a hygro-expansive material (like a specialized polymer or nanocellulose) and the other a passive, non-expansive layer. Differential expansion causes the bilayer strip to bend, acting as a flap valve over an orifice.

- Advantages: Can be designed for various stimuli (temperature, humidity, pH); can generate significant force; can be miniaturized.

- Example: A cellulose-polystyrene bilayer can create a curling motion that opens/ closes a vent, mimicking the stoma's curvature. This approach, published in Science Robotics, allows for programmable curvature and complex motion.

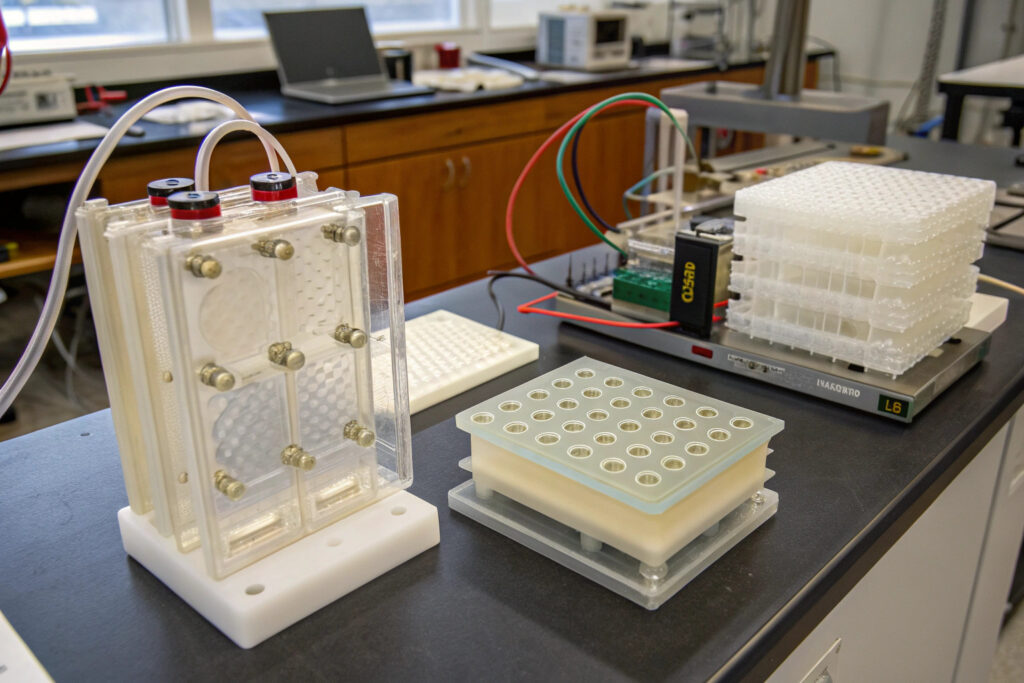

Can MEMS and Electrostatic Systems Mimic Stomatal Speed?

For applications requiring ultra-fast, digitally precise control (like in microfluidic chips or advanced respirators), Micro-Electromechanical Systems (MEMS) are superior.

- Mechanism: These are microscopic flaps or shutters made of silicon or polymer, actuated by electrostatic forces, piezoelectric elements, or thermal expansion. An electrical signal controls the opening and closing directly.

- Advantages: Millisecond response times; precise, repeatable control; integrable with sensors and logic circuits.

- Trade-off: They require external power and control electronics, moving away from the full passivity of biological systems but gaining precision. They represent a "cybernetic" stomata, where the responsive logic is electronic rather than chemical.

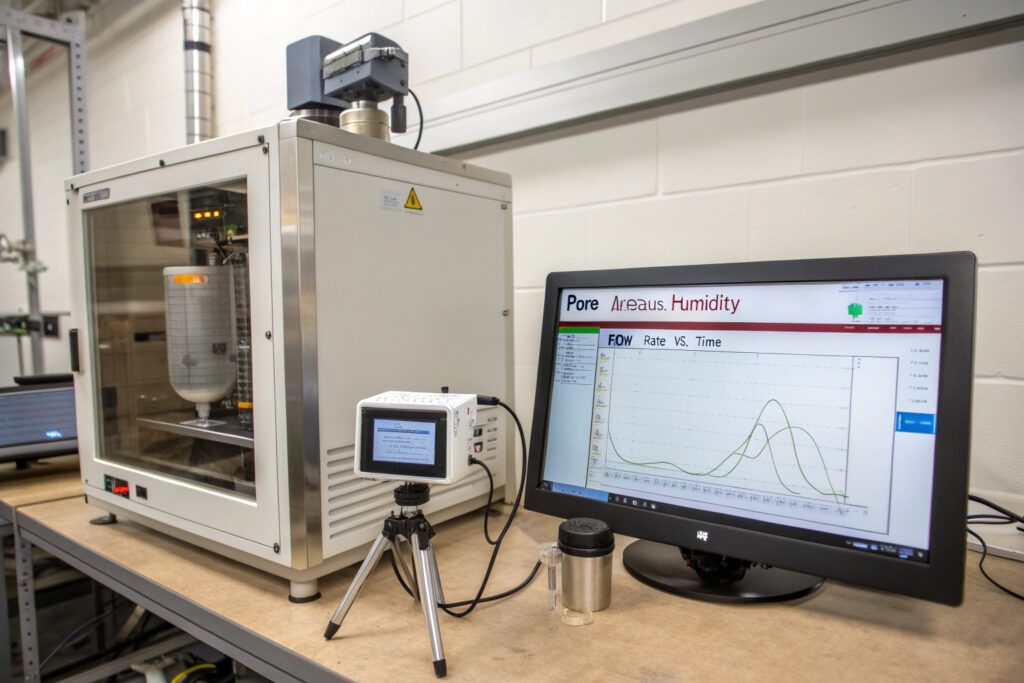

What Are the Key Performance Metrics for Evaluation?

Beyond simply working, a good biomimetic stomatal system must be evaluated on metrics that matter for its intended application.

How Are Flow Modulation and Response Time Measured?

- Dynamic Flow Range: The ratio of maximum to minimum airflow through the system when fully "open" vs. "closed." High-performance systems aim for a range of 10:1 or greater.

- Response Time (τ): The time taken to achieve 63% of the full transition from one state to another (e.g., from 10% to 90% open). Biological stomata operate in tens of seconds to minutes. Advanced hydrogel or bilayer systems can achieve response times of 1-10 seconds. MEMS systems can be in the millisecond range.

- Hysteresis: Does the opening path match the closing path when the stimulus is reversed? Low hysteresis indicates a precise, energy-efficient system with predictable control.

What About Durability and Energy Efficiency?

- Cycle Life: The number of open/close cycles the system can endure before performance degrades (e.g., hydrogel cracking, actuator fatigue). Target: 10,000+ cycles for a daily-use product like a mask.

- Energy per Cycle: For active systems (MEMS), this is measured in microjoules (µJ) per actuation. For passive systems (hydrogels), the "energy" is the ambient gradient (e.g., humidity difference) they harness. The best systems minimize or eliminate external energy input.

- Stimulus Sensitivity: The minimal change in the triggering parameter (e.g., a 5% rise in relative humidity) required to initiate a measurable response.

What Are the Most Promising Applications?

The true test of these systems is their performance in real-world devices. Several applications showcase their unique advantages.

How Can They Revolutionize Smart Masks and PPE?

In masks, traditional exhaust valves are simple one-way flaps. A biomimetic stomatal system could:

- Regulate Humidity Autonomously: Open slightly in response to high exhaled humidity to vent moisture and CO₂, then close during inhalation to maintain filtration efficiency. This balances comfort and protection without user intervention.

- Multi-Stimuli Response: In a hazardous environment, the valve could be designed to close in response to a detected toxic gas, overriding the humidity signal.

- Reduce Breathing Effort: By opening precisely when needed (during exhalation), they can lower overall breathing resistance more effectively than static vents.

This creates a "living," adaptive barrier that optimizes itself continuously.

What Role Could They Play in Smart Buildings and Agriculture?

- Building Skins: Integrated into façade panels, thousands of stomatal units could regulate indoor air quality and temperature by responding to CO₂, humidity, and sunlight, reducing HVAC energy use by 20-30%. This is the concept of "breathing buildings."

- Greenhouse Films: Polyethylene films with stomatal pores that open at high temperature/humidity to vent excess heat and moisture, and close to conserve water and heat, optimizing crop growth conditions passively.

Conclusion

The best biomimetic stomatal airflow systems are those that successfully translate the core principles of plant biology—stimulus-responsive, osmotic or bilayer actuation, and efficient energy transduction—into robust, scalable engineering designs. While hydrogel and bilayer actuators lead in passive, low-cost applications, MEMS-based systems offer unparalleled speed and control for high-tech devices. The choice depends on the priority: total energy independence versus rapid, precise modulation. As material science advances, we are moving toward hybrid systems that combine the best of both worlds: passive response enhanced by minimal external control. These systems are poised to quietly revolutionize fields from personal wearable technology to sustainable architecture, proving that some of the most advanced solutions are written in the language of biology.

Ready to explore integrating biomimetic airflow control into your next product design? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how bio-inspired ventilation technology can enhance the performance, comfort, and intelligence of your masks or environmental systems.