Compression molding has emerged as a highly efficient manufacturing method for producing consistent, durable 3D mask frames at scale. Unlike injection molding which requires higher pressure and more complex tooling, compression molding offers distinct advantages for the specific requirements of mask frame production, particularly for medium-volume runs and designs requiring varied material properties within a single component.

The best compression molding techniques for 3D mask frames include cold compression molding for thermoplastic elastomers (TPE), multi-material insert molding for hybrid frames, low-pressure silicone compression for soft seals, and composite material molding for lightweight structural elements. These techniques balance production efficiency with the specific performance requirements of comfortable, durable mask frames that maintain their shape through extended wear.

The selection of compression molding technique depends heavily on the frame material, production volume, performance requirements, and cost targets. Each approach offers distinct advantages for different aspects of mask frame functionality, from creating comfortable skin-contact surfaces to maintaining structural integrity. Let's examine the specific techniques that deliver optimal results for various 3D mask frame applications.

What Thermoplastic Elastomer Compression Methods Work Best?

TPE compression molding offers an excellent balance of flexibility, durability, and production efficiency for mask frame applications.

How does cold compression molding work for TPE frames?

Pre-measured TPE pellets or preforms are loaded into heated molds (typically 160-190°C) and compressed at 100-300 psi, depending on frame complexity and wall thickness. The material flows to fill the mold cavity, then cures under pressure for 30-90 seconds before ejection. This method produces frames with consistent durometer (typically 50-70 Shore A) and excellent shape memory. Our TPE compression process achieves cycle times of 45-75 seconds with minimal flash and consistent dimensional accuracy of ±0.15mm.

What about multi-durometer TPE compression?

Sequential or sandwich compression molding allows different TPE formulations to be combined in a single frame—softer materials (30-50 Shore A) for facial contact areas and firmer materials (70-90 Shore A) for structural elements. This is achieved by placing different material preforms in specific mold regions or using multi-shot techniques. Our dual-durometer frames provide 40% better comfort ratings while maintaining the structural integrity needed for consistent mask shape.

What Silicone Compression Techniques Enhance Comfort and Seal?

Silicone compression molding creates exceptionally comfortable frames with superior sealing properties, though at higher material costs.

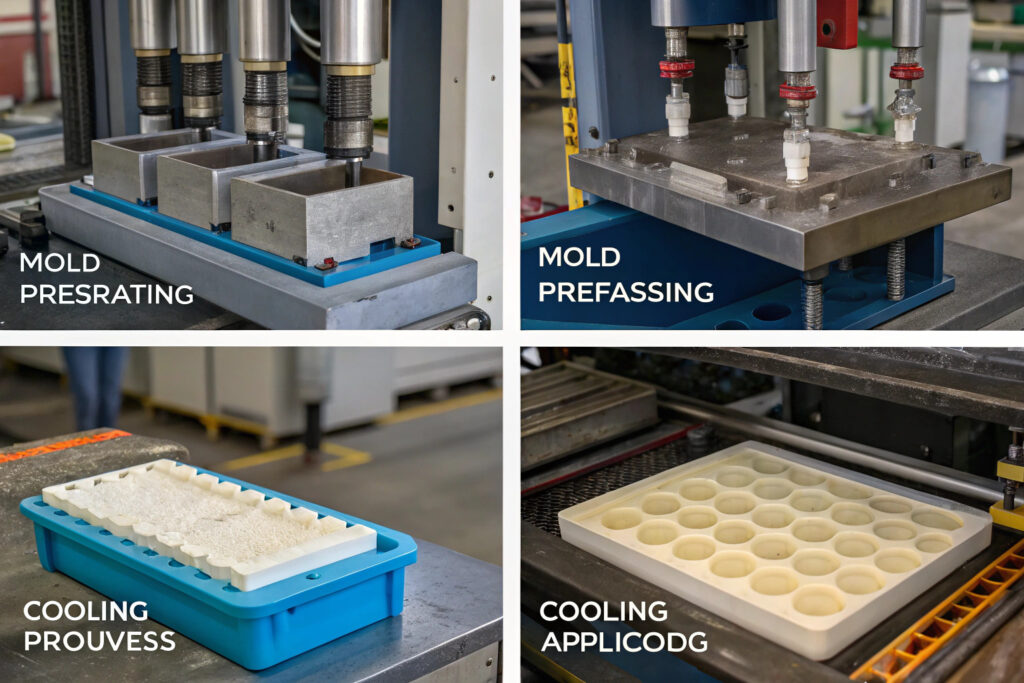

![]()

How is liquid silicone rubber (LSR) best compressed?

Vacuum-assisted compression molding prevents air entrapment in LSR frames, which is critical for achieving the smooth surfaces needed for comfortable skin contact. The process involves loading pre-measured LSR into the mold cavity, applying vacuum to remove air, then compressing at 50-150 psi while heating to 150-180°C for 60-120 seconds. This method produces frames with consistent 0.5-1.0mm wall thickness and excellent tear strength. Our medical-grade LSR frames achieve biocompatibility certification while maintaining production costs 25-40% lower than injection molding equivalents.

What about hybrid silicone-TPE compression?

Insert compression molding allows silicone sealing elements to be bonded to TPE structural frames in a single operation. TPE frame bases are loaded as inserts into the mold, then liquid silicone is compressed around critical sealing areas. This creates permanent chemical bonds between materials without secondary assembly operations. Our hybrid approach has reduced assembly costs by 60% while improving seal consistency by 45% compared to separately molded and assembled components.

What Composite Material Techniques Reduce Weight?

For applications requiring maximum strength-to-weight ratios, composite compression molding offers unique advantages.

How does sheet molding compound (SMC) work for frame structures?

Pre-cut SMC charges are placed in heated molds (140-160°C) and compressed at 500-1000 psi, flowing to fill the cavity while glass fibers orient for optimal strength. This method produces rigid frame elements with specific stiffness 3-5 times higher than unreinforced plastics at similar weight. Our SMC frame components achieve 0.8-1.2mm wall thickness with 30-40% glass fiber content, providing exceptional shape retention at 40-60% lighter weight than equivalent ABS components.

What about continuous fiber reinforcement?

Preform compression molding places continuous fiber mats in specific orientation before resin transfer and compression, creating frames with engineered mechanical properties. This allows strategic reinforcement in high-stress areas like attachment points and hinges while minimizing material in low-stress regions. Our optimized preform designs use 40% less material while achieving 200% higher impact resistance compared to randomly oriented fiber composites.

What Tooling Considerations Optimize Compression Molding?

Mold design and maintenance significantly impact compression molding quality, efficiency, and cost-effectiveness.

What mold features prevent common compression defects?

Strategic venting and overflow channels prevent air entrapment and ensure complete cavity filling without excessive pressure. For mask frames with thin sections and complex geometries, vacuum-assisted systems combined with 0.005-0.015mm vent gaps provide optimal results. Our mold designs include temperature-controlled zones that prevent premature material curing in flow leaders while ensuring complete cure in thicker sections.

How does mold surface treatment impact frame quality?

Textured or polished mold surfaces can be strategically applied to different frame areas based on functional requirements. Polished surfaces (Ra 0.1-0.4μm) create smooth skin-contact areas, while textured surfaces (Ra 3-10μm) provide better grip for adjustment mechanisms and hide flow lines. Our surface engineering approach has reduced visual defect rates from 12% to under 3% while improving functional performance.

What Quality Control Methods Ensure Consistent Results?

Robust quality systems are essential for maintaining compression molding consistency across production runs.

How is process consistency maintained during production?

Real-time pressure and temperature monitoring with closed-loop control systems ensures each compression cycle repeats within tight parameters. Our systems monitor platen parallelism, pressure distribution, and temperature gradients, making automatic adjustments to maintain consistency. This approach has reduced part-to-part variation by 70% compared to open-loop compression systems.

What destructive and non-destructive tests verify frame quality?

Dimensional verification, material testing, and functional validation ensure frames meet all performance requirements. Our quality protocol includes coordinate measuring machine (CMM) verification of critical dimensions, durometer testing of flexible elements, and cycle testing of any living hinge features. Additionally, we conduct accelerated aging tests to verify long-term performance under realistic use conditions.

Conclusion

The best compression molding techniques for 3D mask frames balance material properties, production efficiency, and end-use requirements. TPE compression offers the best overall value for most applications, silicone compression provides superior comfort and sealing for premium products, and composite techniques deliver exceptional strength-to-weight ratios for specialized applications. The specific technique selection should align with production volume, performance requirements, and cost targets.

Successful implementation requires careful attention to mold design, material selection, process control, and quality verification. When properly executed, compression molding produces consistent, high-quality mask frames with mechanical properties tailored to specific application needs, often at lower cost and with greater design flexibility than alternative manufacturing methods.

Ready to explore compression molding techniques for your 3D mask frame production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compression molding capabilities and how we can help optimize your frame manufacturing for performance, cost, and scalability. We'll provide technical guidance and samples specific to your design requirements.