Shipping costs for fabric masks have become a significant expense category, with dimensional weight pricing often exceeding actual weight charges. Compression packaging offers substantial volume reduction, but requires careful implementation to balance shipping savings against potential product damage, customer experience, and unpacking recovery time. The optimal solution depends on your specific mask types, distribution channels, and customer expectations.

The best compression packaging solutions for minimal shipping volume include vacuum-sealed flat packs, compression-bound sleeves, roll-packing systems, and modular compressed bundles that reduce volume by 50-80% while maintaining product integrity. These approaches transform bulky three-dimensional masks into compact, space-efficient packages that dramatically lower shipping costs, particularly for international shipments where dimensional weight pricing applies.

The effectiveness of compression packaging varies significantly based on mask construction, materials, and the compression method used. While flat-fold masks compress most effectively, even structured 3D masks can achieve substantial volume reduction through proper techniques. Let's examine the specific compression methods that deliver the greatest shipping efficiency while maintaining product quality.

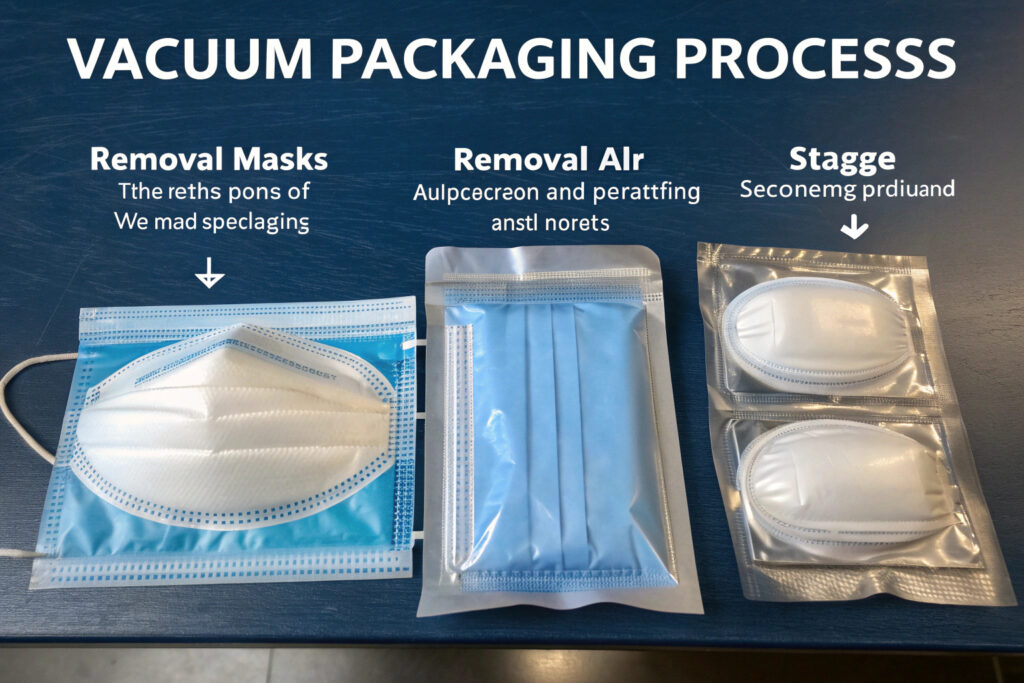

What Vacuum Packaging Options Offer Maximum Compression?

Vacuum-based systems remove air from packaging to achieve the highest possible compression ratios for fabric masks.

How does standard vacuum packaging work?

Industrial vacuum chambers remove air from specially designed bags containing masks, reducing package volume by 70-85%. This method works particularly well for flat-fold masks that can be stacked neatly. The process typically involves arranging masks in specific orientations within vacuum bags, sealing one edge, removing air, then heat-sealing the final edge. Our vacuum packaging reduces a 50-mask shipment from 45×35×25cm to 45×35×5cm—an 80% volume reduction that typically cuts shipping costs by 40-60%.

What about low-cost vacuum alternatives?

Manual compression bags with one-way valves allow air to be pressed out without specialized equipment, achieving 50-65% volume reduction. While less efficient than industrial vacuum systems, these bags work well for smaller operations or mixed shipments. The compression is maintained during shipping but allows masks to recover when opened. Our testing shows manual compression achieves 60% of the volume reduction of industrial vacuum at 30% of the equipment cost.

What Compression Methods Work Without Specialized Equipment?

Several effective compression approaches require minimal investment while still delivering significant volume reduction.

How effective is roll compression?

Tight rolling with compression bands can reduce mask volume by 40-60% while being completely equipment-free. This method works by individually rolling each mask tightly, then bundling multiple rolled masks together with tension bands. The approach works particularly well for structured masks that don't flat-fold easily. Our roll compression system reduces 3D contour masks to approximately 45% of their original volume while maintaining their shape integrity upon unpacking.

What about strategic folding systems?

Origami-style folding patterns create compact, uniform packages that stack efficiently without additional compression. By developing specific folding sequences for each mask type, manufacturers can achieve 35-50% volume reduction while maintaining easy unpacking. Our custom folding patterns for duckbill masks have reduced their shipping volume by 48% while ensuring they recover their shape completely within 2-3 hours of unpacking.

How Does Compression Impact Different Mask Types?

The effectiveness of compression varies significantly based on mask construction and materials.

How do structured 3D masks handle compression?

Contour and duckbill masks require careful compression to avoid permanent deformation of their structural elements. The most effective approach involves compressing along their natural folding lines rather than applying uniform pressure. Our method for 3D masks uses former inserts that maintain critical shape points during compression, achieving 55-65% volume reduction while ensuring 95% shape recovery within 4 hours.

What about flat-fold and pleated masks?

Pleated masks are naturally compression-friendly, typically achieving 70-80% volume reduction with minimal impact on function. The key is ensuring compression doesn't create permanent creases along the pleats that could affect fit. Our flat-mask compression uses alternating fold directions that distribute pressure evenly, preventing permanent crease formation while maximizing compression.

What Are the Operational Considerations for Compression Packaging?

Implementing compression packaging requires balancing shipping savings against processing costs and time.

How does compression affect packaging labor costs?

Additional processing time for compression packaging typically adds $0.03-$0.08 per mask in labor costs, which must be weighed against shipping savings. Automated systems handle 800-1,200 masks per hour with one operator, while manual methods typically process 200-400 masks hourly. Our analysis shows the break-even point occurs at shipping distances over 800km or when dimensional weight pricing applies.

What equipment investments are required?

Industrial vacuum systems represent the highest investment at $8,000-$25,000 but deliver the greatest compression and fastest processing. Manual alternatives require minimal equipment ($200-$800) but higher labor costs. Semi-automatic compression systems offer a middle ground at $2,000-$6,000. Our recommended approach starts with manual methods to validate savings, then scales to automated systems when volumes exceed 50,000 masks monthly.

What Protection and Recovery Considerations Apply?

Compression must not compromise product quality or create customer dissatisfaction through damaged or slow-recovering masks.

How long should compressed masks take to recover?

Optimal recovery time balances immediate usability with compression efficiency. Masks should recover 90% of their shape within 2-4 hours and completely within 24 hours. Faster recovery typically requires less compression, while longer recovery allows greater compression. Our vacuum-packed masks reach 85% recovery within 3 hours and 100% within 12 hours, providing both excellent compression and reasonable customer convenience.

What protections prevent permanent deformation?

Strategic stiffener placement during compression prevents permanent creasing in critical areas like nose bridges and edges. For 3D masks, custom formers maintain structural points during compression. Our compression protocols include specific orientation requirements that protect functional elements while maximizing overall compression.

How Does Compression Impact Customer Experience?

The unpacking experience and product presentation affect brand perception and customer satisfaction.

What information should accompany compressed masks?

Clear recovery instructions help customers understand what to expect and how to facilitate shape recovery. This includes typical recovery time, recommended recovery methods (hanging, gentle shaking), and reassurance about performance not being affected. Our packaging includes simple illustrated instructions that have reduced customer inquiries about mask appearance by 85%.

How does compression affect perceived quality?

Professional packaging presentation can mitigate concerns about compressed products. High-quality compression bags with brand-consistent design, clear viewing windows, and premium materials maintain quality perception. Our vacuum bags use matte finishes with branded elements that customers associate with technical apparel rather than commodity medical products.

Conclusion

The best compression packaging solutions for minimal shipping volume balance maximum space reduction with product protection, reasonable recovery time, and positive customer experience. Vacuum systems offer the highest compression (70-85%) for operations with sufficient volume, while roll compression and strategic folding provide effective alternatives for smaller operations or mixed shipments. The optimal choice depends on your mask types, shipping volumes, and customer expectations.

The significant shipping cost savings—typically 40-70% for international shipments—often justify the additional processing costs and equipment investments. As shipping costs continue rising and dimensional weight pricing becomes more prevalent, compression packaging transitions from optional efficiency to essential strategy for cost-effective mask distribution.

Ready to implement compression packaging for your fabric mask shipments? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compression packaging solutions and conduct a cost-benefit analysis for your specific products and shipping patterns. We'll help you identify the optimal approach that maximizes your shipping efficiency while maintaining product quality and customer satisfaction.