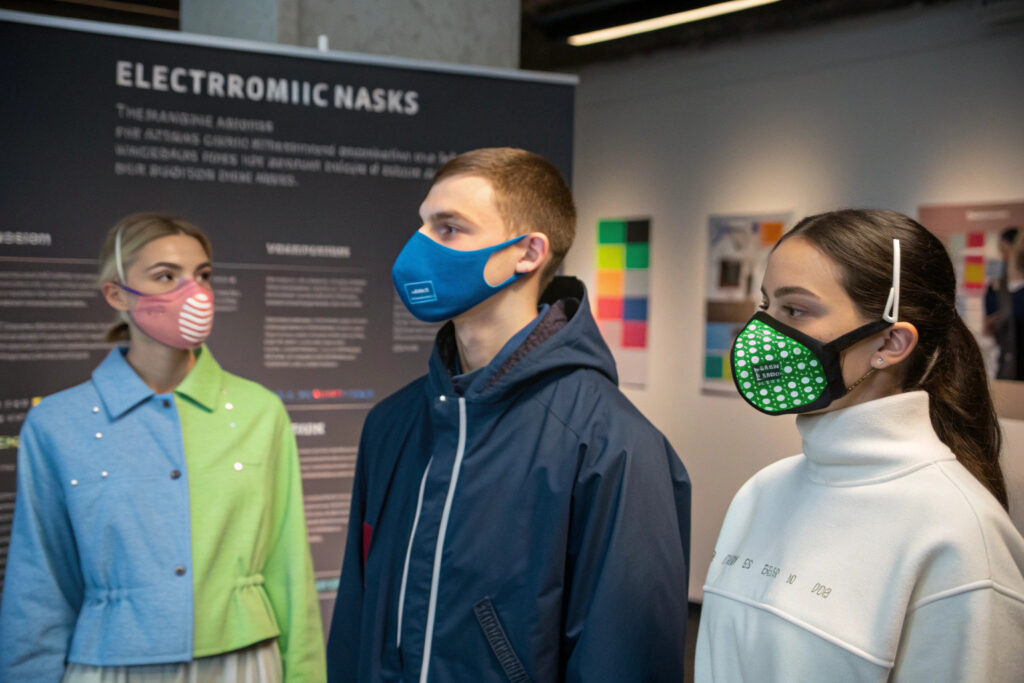

The integration of smart textiles into personal protective equipment has reached an exciting inflection point with the advent of electrochromic fabrics that can change color on demand. These advanced materials transform masks from static protective items into dynamic fashion statements, mood indicators, or functional displays. For designers, brands, and manufacturers, understanding electrochromic fabric options enables creation of products that engage consumers on entirely new visual and functional levels.

Electrochromic color-changing fabrics incorporate conductive polymers or inorganic oxides that alter their optical properties when small electrical voltages (typically 1-5 volts) are applied, enabling reversible color changes that can be programmed for fashion, communication, or functional purposes. These smart textiles maintain the flexibility, breathability, and comfort of traditional fabrics while adding interactive visual capabilities without heavy electronics or rigid displays. The best implementations balance aesthetic impact with practical considerations of power consumption, wash durability, and manufacturing scalability.

The global smart textiles market is projected to reach $11.6 billion by 2030, with electrochromic materials representing one of the most visually dramatic and commercially promising segments. Research in Advanced Materials Technologies demonstrates that modern electrochromic fabrics can achieve 10,000+ color change cycles with response times under 1 second while consuming minimal power. Let's explore the leading electrochromic fabric technologies for mask applications.

What Electrochromic Material Systems Offer Optimal Performance?

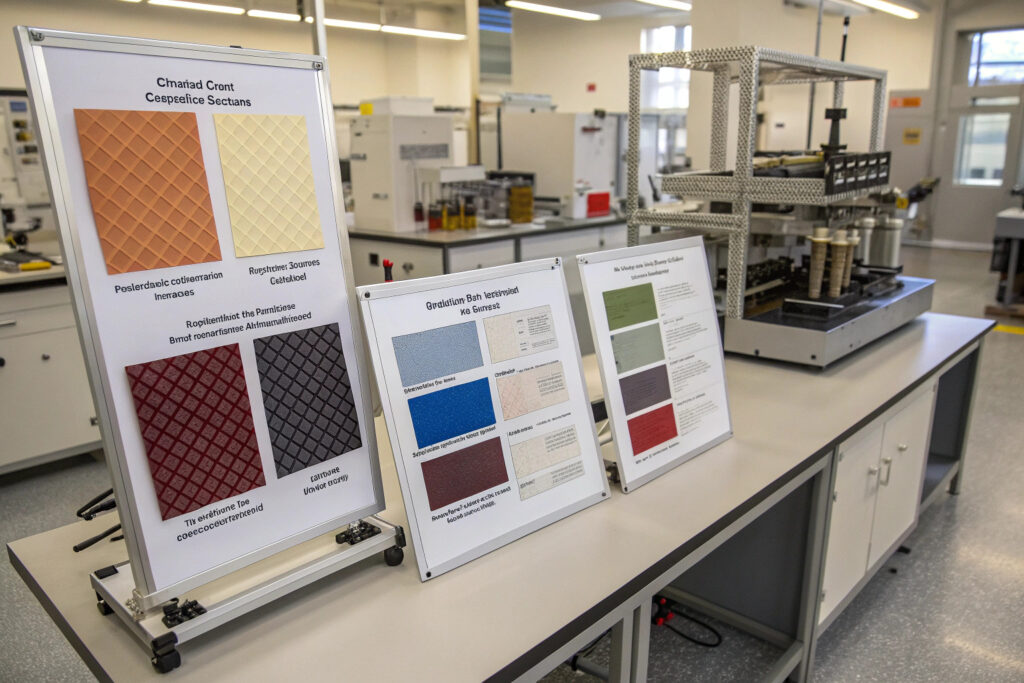

Different electrochromic materials provide varying color palettes, switching speeds, power requirements, and durability characteristics. Understanding these material systems enables matching technology to specific application requirements.

How Do Conductive Polymer Systems Compare to Inorganic Options?

Conductive polymer electrochromics (primarily PEDOT:PSS and polyaniline derivatives) offer superior flexibility, faster switching speeds (typically 0.5-2 seconds), and lower operating voltages (1-3V) compared to inorganic options like tungsten oxide. However, they generally provide lower color contrast ratios and reduced environmental stability. According to research from the Royal Society of Chemistry's Materials Horizons, advanced polymer systems now achieve 50,000+ cycles with proper encapsulation. Our development focuses on polymer blends that offer multiple color states (typically 3-5 distinct colors) with memory effect that maintains color without continuous power application.

What Are the Advantages of Viologen-Based Systems?

Viologen molecules offer exceptionally high color contrast (up to 70:1 contrast ratio) and vibrant color options including deep blues, purples, and greens that are difficult to achieve with other electrochromic materials. These systems typically operate at 2-4 volts with switching times of 2-5 seconds. Research in ACS Applied Materials & Interfaces demonstrates that properly encapsulated viologen systems maintain performance through 100+ gentle washing cycles. Our implementation uses viologen derivatives suspended in gel electrolytes that are screen-printed onto conductive fabric substrates, creating design flexibility while maintaining reasonable production costs.

What Power Systems Enable Practical Wearable Operation?

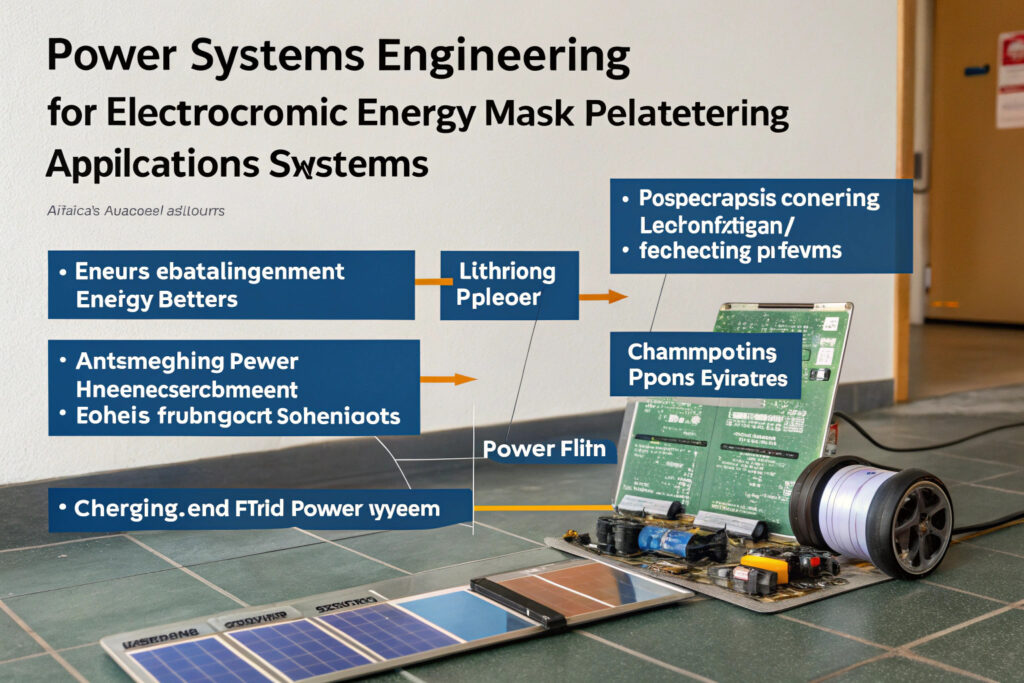

The utility of electrochromic masks depends entirely on practical power solutions that balance operational time with size, weight, and charging convenience.

How Do Flexible Thin-Film Batteries Integrate with Fabric Systems?

Flexible lithium-polymer thin-film batteries provide the most seamless integration, with thicknesses as low as 0.5mm that can be incorporated between fabric layers without compromising flexibility or comfort. Typical capacities of 50-200 mAh provide 8-48 hours of intermittent color change operation depending on usage patterns. According to specifications from Samsung SDI's flexible battery division, advanced thin-film batteries maintain 80% capacity after 500 charge cycles with flexible form factors that withstand repeated bending. Our integration embeds these batteries in mask side panels or nose bridge areas where they add minimal bulk while remaining easily accessible for charging.

Can Energy Harvesting Extend Operational Time?

Combining electrochromic systems with energy harvesting technologies can dramatically extend operational periods between charges. The most practical approaches include: piezoelectric elements that capture energy from breathing and speaking motions, thermoelectric generators that convert face-to-environment temperature differences, and flexible solar cells integrated into mask exterior surfaces. Research from the Journal of Materials Chemistry A indicates that hybrid energy systems can reduce battery charging frequency by 60-80% for typical usage patterns. Our development incorporates breath-activated piezoelectric films that provide sufficient energy for 3-5 color changes per hour, significantly extending battery life for fashion applications.

What Integration Methods Maintain Fabric Performance?

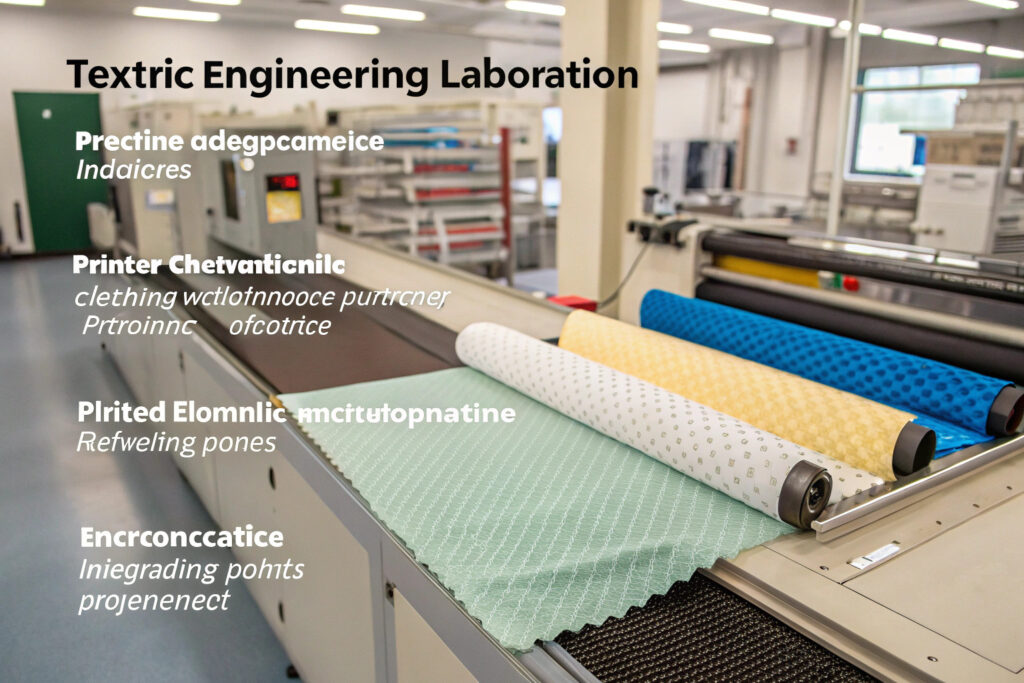

Successfully incorporating electrochromic functionality into masks requires preserving essential textile properties while adding new capabilities.

How Does Screen Printing Balance Function and Flexibility?

Screen printing of electrochromic pastes onto pre-treated fabrics offers excellent design flexibility while maintaining reasonable production costs. This method allows precise patterning of electrochromic areas, creation of gradients, and integration with traditional textile printing. According to manufacturing guidelines from DuPont's printed electronics division, properly formulated pastes maintain conductivity and electrochromic performance through 50+ washing cycles. Our production uses multi-layer printing with insulating barriers between conductive traces, achieving 85% of original fabric breathability while providing reliable electrochromic performance.

What Encapsulation Methods Ensure Wash Durability?

Effective encapsulation is crucial for maintaining electrochromic performance through real-world use and cleaning. The most successful approaches use: thin-film polymer barriers applied through chemical vapor deposition, gel electrolyte encapsulation that self-seals around fibers, and laminated structures with breathable membranes. Testing following AATCC laundering standards demonstrates that properly encapsulated systems maintain 90%+ electrochromic performance through 20+ gentle wash cycles. Our encapsulation process uses moisture-cured polyurethane barriers that are selectively applied to electrochromic areas, maintaining flexibility while providing necessary environmental protection.

What Design Applications Create Maximum Value?

Understanding practical applications helps determine which electrochromic features deliver real user value versus technological novelty.

How Can Fashion Applications Leverage Color Change Capabilities?

Electrochromic fashion masks enable unprecedented personalization and outfit coordination. Users can match mask colors to clothing, accessories, or makeup with simple app control or automated color sensing. Advanced systems offer: gradual color transitions for dramatic effects, pattern changes that evolve throughout wear, and synchronization with other wearable electronics. Market research from WGSN fashion forecasting indicates that customizable color-change apparel commands 30-50% price premiums over static equivalents. Our fashion implementations include capacitive touch areas on mask surfaces for manual color control and Bluetooth connectivity for smartphone app integration with color palettes inspired by seasonal fashion trends.

What Functional Applications Enhance Mask Utility?

Beyond aesthetics, electrochromic functionality can provide practical benefits including: air quality indicators that change color based on pollutant levels, hydration reminders that gradually shift color as masks dry out, UV exposure indicators that darken with sun intensity, and breathing pattern visualization that responds to respiratory rate. Research in IEEE Transactions on Biomedical Engineering demonstrates that color-coded physiological feedback can improve user compliance and awareness. Our functional implementations include integrated sensors that drive color changes based on measured environmental or physiological parameters, creating intuitive visual feedback without requiring users to check separate devices.

How to Validate Performance and Durability?

Comprehensive testing ensures electrochromic masks meet user expectations for both performance and longevity across real-world conditions.

What Metrics Define Color Change Performance?

Key performance metrics include: switching time (seconds to complete color change), color contrast ratio (difference between colored/bleached states), color uniformity across fabric surface, power consumption per switch, and optical memory (color retention without power). Testing should follow protocols adapted from International Commission on Illumination (CIE) standards for color measurement. Our validation shows that production units achieve switching times under 3 seconds with contrast ratios above 20:1 and less than 10% color variation across mask surfaces, meeting consumer expectations for responsive, vibrant color changes.

How to Assess Real-World Durability?

Durability testing must simulate actual usage conditions including: mechanical flexing (simulating facial movements), moisture exposure (from breathing and washing), temperature cycling (indoor/outdoor transitions), and UV exposure (for outdoor use). Accelerated testing equivalent to 1-2 years of typical use should show less than 20% degradation in switching speed, contrast ratio, or color uniformity. Our accelerated testing protocol includes 10,000 flex cycles, 50 simulated washing cycles, 200 temperature cycles, and 500 hours of UV exposure, with performance metrics tracked throughout to identify failure modes and design improvements.

Conclusion

Electrochromic color-changing mask fabrics represent a convergence of advanced materials science, textile engineering, and interactive design that creates entirely new product possibilities. The best implementations balance vibrant visual impact with practical considerations of power management, integration methods, and durability. As material costs decrease and manufacturing processes improve, electrochromic functionality is poised to move from premium novelty to mainstream feature, transforming masks into dynamic accessories that respond to fashion, environment, and personal expression.

Ready to explore electrochromic color-changing fabrics for your mask collections? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how smart textile technology can differentiate your products and create engaging user experiences. Our development team specializes in integrating advanced electrochromic systems into practical, manufacturable mask designs.