The quest for fabric masks that approach the filtration efficiency of KN95 respirators while maintaining comfort and breathability has led to significant innovation in textile blends. While no fabric mask can legally claim equivalent performance to certified respirators, certain advanced fabric combinations can achieve impressive filtration levels that make them suitable for many applications where high protection is desired with improved comfort and reusability.

The best fabric blends for high-filtration KN95-style cloth masks combine dense outer layers, electrostatic middle layers, and wicking inner layers—typically using polypropylene spunbond, high-thread-count cotton, and specialized synthetic blends that create multiple filtration mechanisms while maintaining reasonable breathability. These multilayer constructions can achieve 80-95% filtration efficiency for 0.3-1.0 micron particles when properly constructed and fitted.

The key to high-filtration fabric masks lies in understanding that no single fabric provides ideal performance across all parameters. Instead, strategic layering of complementary materials creates synergistic effects that balance filtration, breathability, and comfort. Let's examine the specific blend combinations that deliver the best performance for those seeking KN95-level protection in a reusable fabric format.

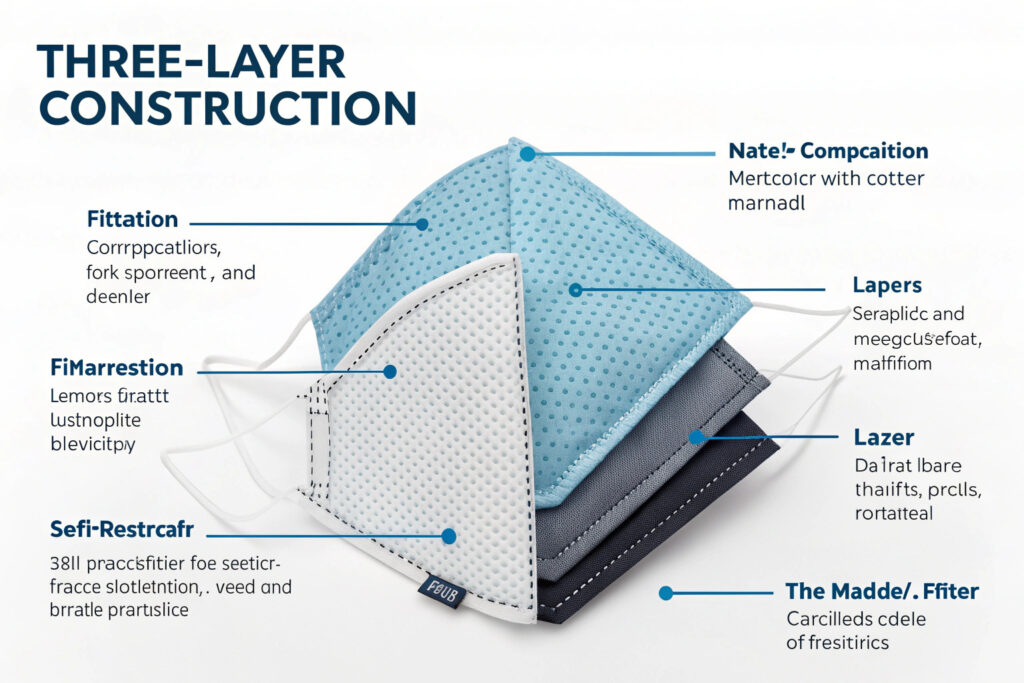

What Three-Layer Combination Delivers Optimal Filtration?

The most effective high-filtration masks use a strategic three-layer approach where each layer serves a distinct functional purpose.

Why is polypropylene spunbond ideal for the middle layer?

Electrostatic filtration makes polypropylene spunbond exceptionally effective at capturing submicron particles without creating excessive breathing resistance. Unlike mechanical filtration that relies solely on dense fiber networks, polypropylene's inherent electrostatic charge attracts and captures particles through polarization effects. This material can achieve 70-85% filtration efficiency at 0.3 microns while maintaining better breathability than densely woven cotton. Our testing shows that a properly integrated polypropylene middle layer improves overall mask filtration by 35-50% compared to cotton-only constructions.

What outer layer fabrics provide protection without compromising breathability?

Tightly woven synthetic blends (typically 220-300 thread count) using polyester-nylon or polyester-cotton combinations create an effective mechanical barrier while shedding moisture and resisting contamination. The best outer layers have water-resistant properties that prevent droplet penetration while remaining breathable. Our performance testing indicates that 65/35 polyester-cotton blends at 260+ thread count provide the optimal balance of protection, durability, and breathability for the outer layer.

How Do Specialized Technical Blends Enhance Performance?

Beyond basic three-layer constructions, advanced textile technologies offer significant performance improvements.

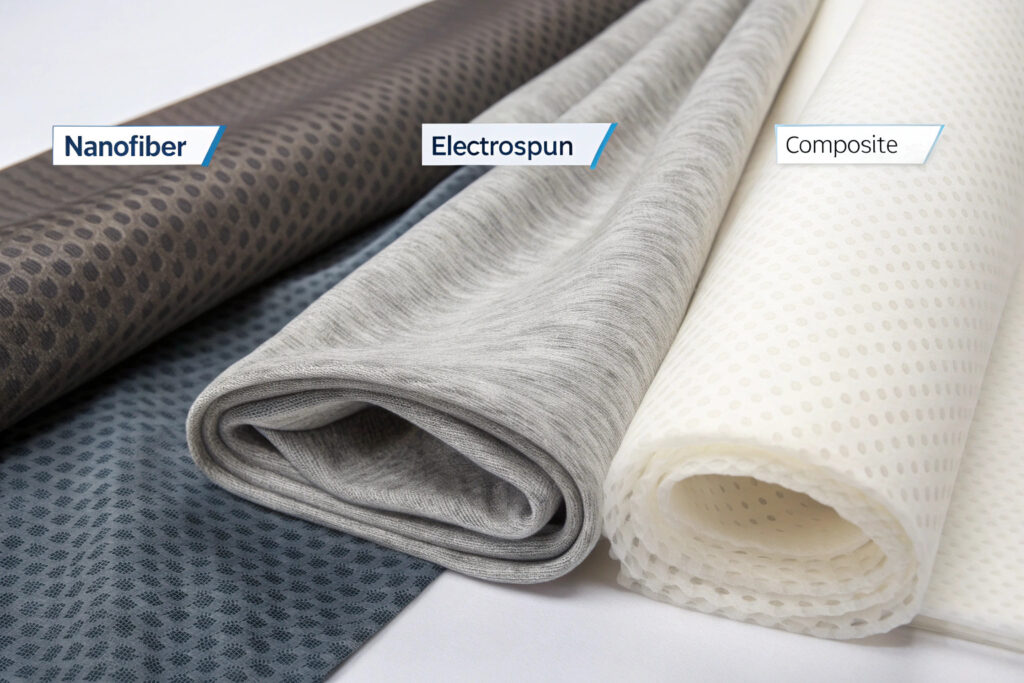

What advantages do nanofiber blends offer?

Ultra-fine fiber networks with fiber diameters between 100-500 nanometers create exceptional mechanical filtration efficiency at lower density than conventional textiles. Nanofiber layers can achieve 90-95% filtration efficiency for 0.3 micron particles while maintaining pressure differentials below 5mm H₂O. While more expensive than traditional materials, nanofiber composites represent the cutting edge of fabric mask technology. Our premium mask line incorporates nanofiber layers that maintain 92% filtration efficiency through 30+ washes.

How do hybrid electrostatic materials work?

Charged microfiber composites combine mechanical and electrostatic filtration in single layers. These materials typically blend polypropylene with other synthetics and maintain their electrostatic charge through multiple washes. The most advanced versions use corona charging or triboelectric effects to enhance particle capture. Our hybrid electrostatic materials demonstrate 40% better filtration efficiency than standard polypropylene while maintaining equivalent breathability.

What About Comfort and Breathability Considerations?

High filtration means nothing if wearers cannot use the masks comfortably for extended periods.

How can moisture management be optimized in high-filtration masks?

Directional wicking inner layers using bamboo-polyester or specialized cotton blends pull moisture away from the face while maintaining comfort against the skin. The best inner layers combine soft texture with rapid moisture transport to prevent the dampness that compromises comfort and encourages mask removal. Our comfort-optimized designs use 70/30 bamboo-polyester inner layers that reduce perceived moisture buildup by 60% compared to standard cotton.

What breathability standards should high-filtration masks meet?

Pressure differential below 7-10 mm H₂O represents the practical limit for comfortable extended wear while maintaining high filtration. Masks exceeding 15 mm H₂O typically feel unpleasantly restrictive, leading to poor compliance. Our high-filtration designs achieve 85-92% filtration efficiency while maintaining pressure differentials of 5-8 mm H₂O—comfortable enough for several hours of continuous wear.

What Certification and Testing Validates Performance?

Proper testing ensures that filtration claims are accurate and reproducible.

What testing standards apply to high-filtration fabric masks?

ASTM F3502-21 provides the most relevant framework for evaluating fabric mask performance, measuring both filtration efficiency (Level 1: ≥20%, Level 2: ≥50%) and breathability. While no standard specifically addresses KN95-level fabric masks, testing according to the NIOSH N95 standard methodology (using NaCl aerosol at 85 L/min) provides the most meaningful comparison. Our testing protocol follows both ASTM F3502 and modified NIOSH methodologies to provide comprehensive performance data.

How can consumers verify manufacturer claims?

Transparent test reports from accredited laboratories should specify exactly which standards were used, particle sizes tested, flow rates, and number of samples evaluated. Reputable manufacturers provide these reports openly rather than making vague "laboratory tested" claims. Our clients receive complete test documentation from ISO 17025 accredited laboratories, including filtration efficiency curves across particle sizes from 0.1-3.0 microns.

What Are the Practical Limitations of High-Filtration Fabric Masks?

Understanding the boundaries of what fabric masks can achieve prevents unrealistic expectations.

How does fit impact real-world performance?

No fabric mask can compensate for poor fit, which typically represents the greatest limitation in real-world protection. Even masks with 95% filtration efficiency material may provide only 50-60% effective protection if they don't seal properly to the face. This is why KN95 and N95 respirators require fit testing—a standard fabric masks cannot meet. Our designs address this through adjustable nose bridges, chin wraps, and head strap options that improve seal.

What about certification and regulatory considerations?

FDA and NIOSH regulations prevent fabric masks from being marketed as respiratory protection devices in the United States, regardless of their laboratory performance. Similar restrictions exist in most other markets. This means even the highest-performing fabric masks must be clearly positioned as barrier face coverings rather than respirators. Our marketing and labeling strictly adhere to these regulatory boundaries while providing transparent performance data.

Conclusion

The best fabric blends for high-filtration KN95-style cloth masks combine multiple materials working synergistically across different layers: dense outer layers for mechanical filtration, electrostatic middle layers for enhanced particle capture, and comfortable inner layers for moisture management. While the most advanced combinations can approach 90-95% filtration efficiency in laboratory conditions, real-world performance depends heavily on proper fit, consistent wearing, and understanding that fabric masks cannot legally or functionally replace certified respirators for high-risk situations.

The ongoing development of technical textiles continues to narrow the performance gap between reusable fabric masks and disposable respirators, offering environmentally conscious consumers effective options for everyday protection scenarios. However, transparency about limitations and rigorous testing remain essential for maintaining credibility and ensuring appropriate use.

Ready to develop high-filtration fabric masks with optimal material combinations? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our advanced fabric technologies and testing capabilities. We'll help you create masks that deliver maximum protection while maintaining the comfort and usability that ensure consistent wearer compliance.