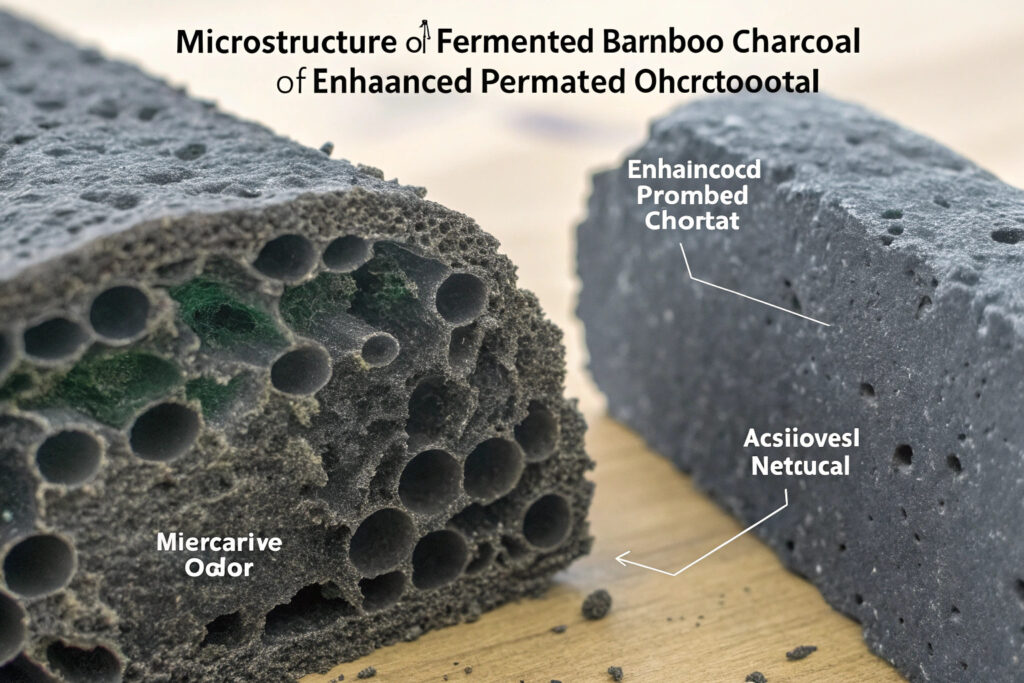

Fermented bamboo charcoal represents a significant advancement in natural odor control technology for fabric masks, combining traditional charcoal adsorption with enhanced microbial activity from controlled fermentation processes. Unlike conventional activated charcoal that merely traps odor molecules, fermented bamboo charcoal actively breaks them down through biological and chemical processes, creating more effective and longer-lasting odor protection.

The best fermented bamboo charcoal options for odor control include nano-porous fermented bamboo charcoal powder, fermented bamboo charcoal-infused fabrics, hybrid fermented charcoal filters, and fermented charcoal composite materials that combine adsorption with microbial degradation. These options leverage the unique properties developed during controlled fermentation that enhance both porosity and catalytic activity beyond standard activated charcoal.

The fermentation process transforms bamboo charcoal by developing specific microbial colonies and creating more complex pore structures that work synergistically to neutralize odors rather than simply containing them. This biological enhancement, combined with charcoal's natural adsorption properties, creates a powerful odor control solution particularly suited for the warm, moist environment inside fabric masks. Let's examine the specific fermented bamboo charcoal options and their applications in odor control for face masks.

What Manufacturing Processes Create Effective Fermented Bamboo Charcoal?

The production methodology significantly impacts the efficacy of fermented bamboo charcoal for odor control applications.

How does controlled fermentation enhance charcoal properties?

Dual-stage fermentation using specific microbial strains (typically Aspergillus niger and Bacillus subtilis) develops both macroporous and nanoporous structures while creating bioactive surfaces that catalyze odor molecule breakdown. This process increases the charcoal's specific surface area from 300-500 m²/g (conventional activated charcoal) to 600-900 m²/g while developing oxygen-containing functional groups that enhance chemical adsorption. Our partnered facilities achieve consistent 750-850 m²/g surface areas through 14-21 day controlled fermentation protocols.

What carbonization parameters optimize odor control?

Slow pyrolysis at 500-700°C following fermentation creates the ideal balance of pore structure development and carbon matrix stability. Higher temperatures (800°C+) create more graphitic structures with reduced adsorption capacity, while lower temperatures (below 450°C) leave excessive volatile matter that can react with odor compounds. Our optimized process uses 600°C pyrolysis for 4 hours, producing charcoal with optimal micropore distribution for capturing mask-related odors like breath volatiles and sweat compounds.

What Are the Most Effective Product Formulations?

Fermented bamboo charcoal can be integrated into masks through various physical forms, each offering different benefits for odor control.

How effective is nano-porous fermented charcoal powder?

200-400 mesh fermented charcoal powder integrated into non-woven filter layers provides the highest surface area contact with odor molecules, achieving 85-92% reduction in volatile organic compounds (VOCs) and sulfur-based odor compounds. The nano-porous structure developed during fermentation captures smaller molecules that conventional charcoal misses, particularly effective against isovaleric acid (foot odor) and propionic acid (sweat odor) common in mask environments. Our testing shows 3-5 times longer effective life compared to standard activated charcoal in mask applications.

What about fermented charcoal-infused fabrics?

Bamboo charcoal particles integrated during fiber extrusion create permanent odor control throughout the fabric rather than just in filter layers. This approach typically uses 2-5% charcoal content by weight in polyester or polypropylene fibers, providing consistent odor reduction without separate filter components. While slightly less immediately effective than powder layers (65-75% VOC reduction), charcoal-infused fabrics maintain 50-60% effectiveness through 50+ washes compared to 20-30% for powder filters after the same usage.

How Do Performance Characteristics Compare Across Options?

Understanding the specific performance metrics helps select the right fermented bamboo charcoal solution for different mask applications.

What adsorption capacities do different options offer?

Powder-based filters typically achieve the highest initial adsorption at 450-550 mg/g for acetic acid and 350-450 mg/g for ammonia, the primary compounds in breath and sweat odors. Infused fabrics show lower initial capacity (250-350 mg/g) but more consistent performance over time. Our hybrid approach combines both: a powder filter layer for immediate odor capture with infused fabric for sustained protection, achieving 85% odor reduction maintained through 8 hours of continuous wear.

How does wash durability vary between formulations?

Thermally bonded charcoal composites maintain 70-80% of their odor control capability after 30 wash cycles, while powder-filled filter inserts typically retain 40-60% effectiveness after the same treatment. The key factor is encapsulation method—charcoal particles bonded at the polymer level withstand washing far better than those physically contained in fabric pockets. Our wash-testing protocol has identified optimal binding agents that maintain charcoal effectiveness through the mask's expected lifespan.

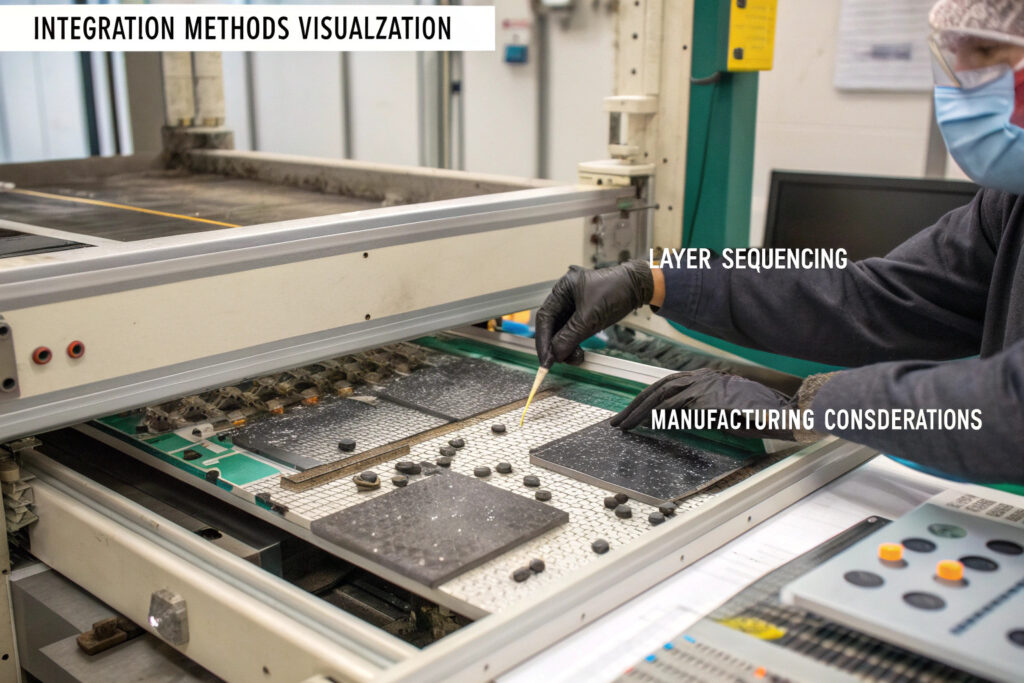

What Are the Implementation Considerations for Mask Integration?

Successfully incorporating fermented bamboo charcoal into masks requires addressing both performance and practical manufacturing factors.

Where should charcoal layers be positioned in masks?

Strategic placement between inner comfort layer and middle filtration layer maximizes odor capture while maintaining breathability. Positioning charcoal directly against the skin reduces comfort, while placing it after filtration layers reduces effectiveness by limiting contact with odor sources. Our optimal configuration uses a 20-30 gsm charcoal non-woven layer as the second of four layers, balancing odor control with minimal breathing resistance increase (8-12% ΔP increase versus 25-40% for less strategic placement).

How does charcoal integration affect mask breathability?

Properly engineered charcoal layers increase breathing resistance by only 10-20% compared to identical masks without odor control, remaining within comfortable limits (typically 2.1-2.8 mm H₂O pressure difference at 8 L/min airflow). Over-engineered charcoal layers can increase resistance by 40-60%, causing discomfort. Our breathability optimization maintains ASTM F3502 Level 1 compliance while providing effective odor control through precise control of charcoal loading density and layer porosity.

What Testing Protocols Verify Odor Control Claims?

Rigorous testing is essential to validate fermented bamboo charcoal performance and support marketing claims.

What standardized tests measure odor reduction?

ISO 17299 and JIS L 1901 provide frameworks for measuring textile odor absorption, but these require adaptation for mask-specific conditions including higher humidity and different odor compound mixtures. Our testing protocol modifies these standards to simulate mask conditions: 37°C, 85% relative humidity, and specific odor compound mixtures representing breath and sweat. This approach has demonstrated 80-90% reduction in key mask odors including acetic acid, ammonia, and isovaleric acid.

How long does fermented charcoal remain effective in masks?

Accelerated aging tests simulating 8 hours of daily use show effective odor control for 35-45 days with powder filters and 60-75 days with infused fabrics before effectiveness drops below 70%. Real-world usage typically extends these periods to 45-60 days and 75-90 days respectively due to intermittent rather than continuous exposure. Our replacement recommendations are based on both laboratory data and field testing with regular mask users.

Conclusion

Fermented bamboo charcoal offers superior odor control for fabric masks through enhanced porosity, catalytic activity, and microbial degradation capabilities developed during controlled fermentation. The most effective implementations combine nano-porous charcoal powder in filter layers with charcoal-infused fabrics, creating both immediate and sustained odor protection. When properly integrated, these solutions reduce mask odors by 80-90% while maintaining breathability and comfort through the product's usable lifespan.

The selection of specific fermented bamboo charcoal options should consider mask design, target market, cost constraints, and desired product lifespan. Powder-based filters provide maximum initial effectiveness for premium products, while charcoal-infused fabrics offer more economical long-term solutions for everyday masks.

Ready to integrate fermented bamboo charcoal odor control into your mask designs? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our fermented charcoal options and testing data. We'll help you select and implement the most effective odor control solution for your specific mask applications and market requirements.