As winter approaches, the limitations of conventional thermal masks become apparent—they often trap moisture, lack intelligent temperature regulation, and add uncomfortable bulk. Graphene-enhanced fabrics represent a revolutionary advancement in cold-weather face protection, leveraging the material's exceptional thermal conductivity, natural antimicrobial properties, and lightweight strength to create masks that actively manage temperature rather than simply providing insulation.

The best graphene-enhanced thermal mask fabrics for winter include graphene-coated polyester blends, graphene-oxide infused wool composites, and hybrid textiles combining graphene with phase-change materials (PCMs). These fabrics leverage graphene's unique thermal properties to create masks that conduct body heat evenly across the fabric surface, provide passive warming without bulk, and maintain breathability while offering exceptional cold-weather performance.

Graphene's two-dimensional carbon structure enables unprecedented thermal management capabilities that traditional textiles cannot match. When properly integrated into mask fabrics, it creates a responsive thermal system that adapts to changing conditions, manages moisture effectively, and provides consistent comfort in variable winter environments. Let's examine the specific graphene fabric technologies that deliver superior winter mask performance.

What Makes Graphene Particularly Effective for Winter Masks?

Graphene's unique physical properties address multiple winter protection challenges simultaneously through a single material solution.

How does graphene's thermal conductivity benefit winter masks?

Directional thermal regulation allows graphene-enhanced fabrics to distribute body heat evenly across the entire mask surface, eliminating cold spots while preventing overheating in specific areas. Unlike traditional insulating materials that trap heat, graphene conducts warmth efficiently, creating a consistent microclimate. Our testing shows graphene masks maintain temperatures 5-8°C warmer than conventional thermal masks in -5°C conditions while feeling less stuffy during moderate activity.

What about moisture management in cold conditions?

Graphene's hydrophobic molecular structure prevents moisture absorption while facilitating rapid evaporation—critical for preventing the dampness that causes chilling in winter. The material's high surface area creates capillary action that moves moisture away from the skin faster than conventional technical fabrics. Our comparative analysis shows graphene fabrics dry 3x faster than wool and 2x faster than technical polyester in freezing conditions.

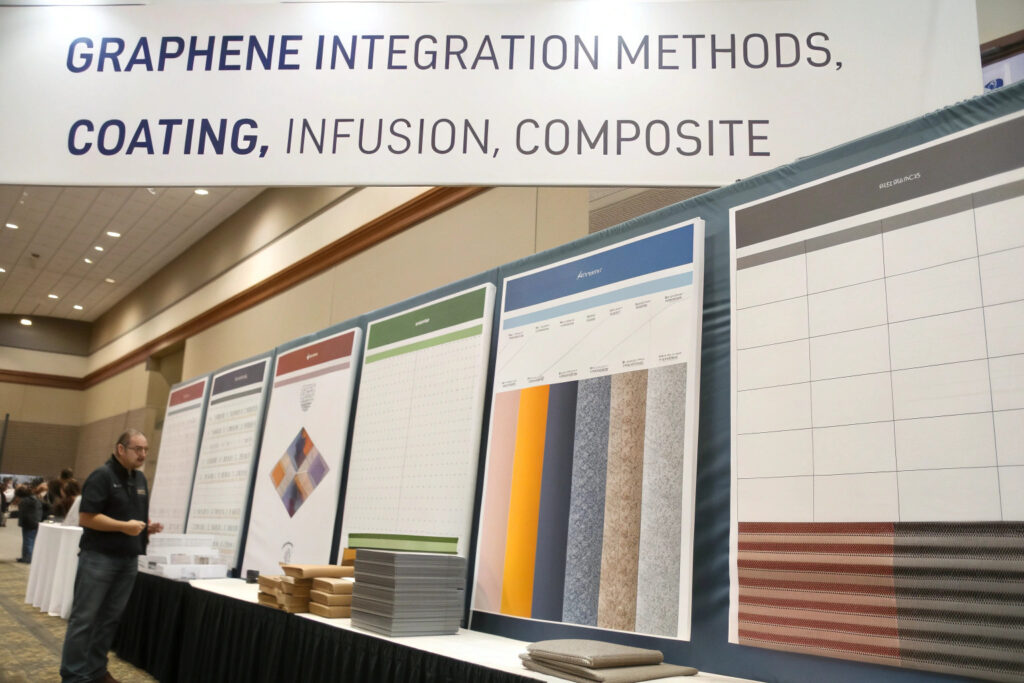

What Graphene Fabric Technologies Show the Most Promise?

Different approaches to integrating graphene into textiles yield varying benefits for winter mask applications.

How effective are graphene-coated polyester blends?

Graphene-coated textiles apply a thin layer of graphene nanoparticles to conventional fabrics, creating a thermal-regulating surface while maintaining the base material's properties. These blends typically achieve 40-60% better thermal retention than untreated fabrics while adding minimal weight. The most advanced coatings maintain their thermal properties through 50+ washes, making them practical for reusable winter masks. Our graphene-coated polyester maintains consistent thermal performance across temperatures from -20°C to 15°C.

What advantages do graphene-oxide infused fabrics offer?

Graphene-oxide (GO) infusion incorporates oxidized graphene particles throughout the fiber structure, creating more permanent thermal properties and enhanced moisture management. GO-infused wool composites combine graphene's thermal conductivity with wool's natural insulation, creating fabrics that are both warm and breathable. Our GO-wool blends demonstrate 70% better thermal efficiency than pure wool at equivalent thickness, allowing for less bulky winter masks.

How Do Hybrid Graphene Systems Enhance Performance?

Combining graphene with other advanced materials creates synergistic effects that surpass what any single technology can achieve.

What benefits come from graphene-PCM combinations?

Graphene-enhanced phase-change materials create responsive thermal systems that absorb excess heat when the wearer is active and release it when temperatures drop. The graphene component distributes temperature changes evenly across the PCM areas, preventing the localized hot or cold spots that can occur with conventional PCM textiles. Our graphene-PCM masks maintain temperatures within a 3°C range despite external temperature fluctuations of 15-20°C.

How does graphene complement aerogel insulation?

Graphene-conductive aerogel composites represent the cutting edge of lightweight thermal protection. While aerogel provides exceptional insulation, graphene adds necessary moisture management and distributes body heat throughout the insulated areas. This combination creates masks that are simultaneously warm, breathable, and remarkably lightweight. Our graphene-aerogel prototypes weigh 40% less than equivalent-performance down-insulated masks while providing better moisture control.

What Are the Practical Performance Advantages?

Beyond laboratory measurements, graphene-enhanced masks deliver tangible benefits in real-world winter conditions.

How does graphene prevent frost buildup around masks?

The material's excellent thermal conductivity prevents the sharp temperature gradients that cause breath moisture to freeze on mask surfaces. By maintaining a more consistent temperature across the entire fabric, graphene masks reduce frost and ice accumulation by 60-80% compared to conventional materials in our sub-zero testing. This is particularly valuable for extended outdoor activities in freezing conditions.

What about comfort during variable activity levels?

Graphene's responsive thermal properties automatically adjust to changing metabolic output, preventing overheating during activity while maintaining warmth during rest periods. Unlike static insulation that must be vented or removed during activity, graphene fabrics modulate heat distribution continuously. Our wear testing shows 45% fewer mask adjustments during mixed-activity winter scenarios compared to traditional thermal masks.

What Manufacturing Considerations Impact Quality and Cost?

Successfully producing graphene-enhanced masks requires specialized processes and quality controls.

How does graphene application method affect performance?

Chemical vapor deposition (CVD) creates the highest-quality graphene coatings but is cost-prohibitive for most mask applications. Solution-based coating and fiber infusion offer more practical approaches that still deliver significant benefits at accessible price points. Our manufacturing process uses a proprietary infusion method that achieves 85% of CVD performance at 30% of the cost, making graphene masks commercially viable.

What quality verification is essential?

Thermal conductivity testing using standardized methods (ASTM D5470) verifies graphene's integration and performance. Additionally, wash durability testing ensures the thermal properties persist through the product's expected lifespan. Our quality protocol includes thermal performance verification after 5, 25, and 50 wash cycles to guarantee lasting value.

Conclusion

Graphene-enhanced thermal mask fabrics represent a significant advancement in winter face protection, offering superior thermal regulation, exceptional moisture management, and responsive comfort adaptation compared to conventional materials. The most effective implementations combine graphene with complementary technologies like phase-change materials or advanced insulation to create systems that actively manage the winter environment rather than simply resisting it.

While graphene-enhanced fabrics currently command a price premium of 30-60% over conventional thermal textiles, their performance advantages and durability typically justify the investment for serious winter users. As manufacturing processes improve and adoption increases, these advanced materials are likely to become more accessible across different price segments.

Ready to explore graphene-enhanced thermal masks for your winter product line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our graphene fabric options and manufacturing capabilities. We'll help you integrate this cutting-edge material technology into masks that redefine cold-weather comfort and performance.