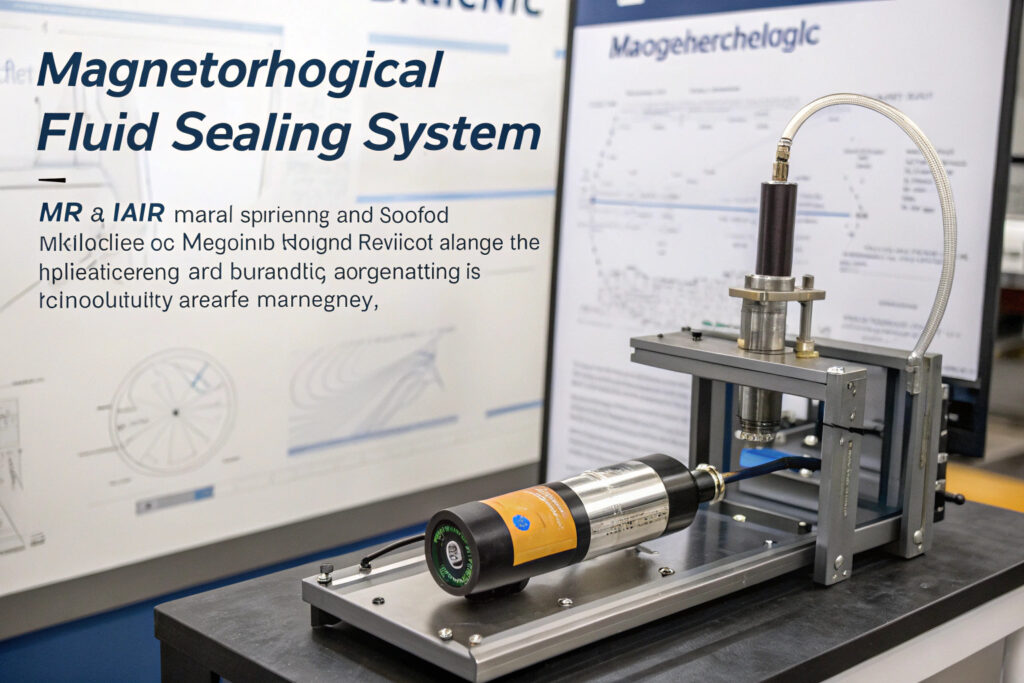

The quest for dynamic, adaptive sealing solutions has led to significant innovation in materials science, with magnetorheological (MR) fluid sealing systems emerging as a particularly sophisticated technology. These systems enable real-time, precise control of sealing integrity and leakage rates through the application of magnetic fields, offering transformative potential for applications requiring variable sealing under changing conditions. For engineers in industries ranging from aerospace and automotive to medical devices and advanced manufacturing, understanding the optimal configurations of MR fluid seals is essential for implementing reliable, intelligent sealing solutions.

Magnetorheological fluid sealing systems utilize smart fluids whose viscosity and yield stress can be rapidly and reversibly increased by several orders of magnitude when exposed to a magnetic field, creating controllable barriers that can adapt sealing pressure, stiffness, and leakage tolerance in milliseconds. Unlike traditional static seals, MR fluid seals can actively respond to pressure fluctuations, vibration, wear, or deliberate operational changes, making them ideal for applications where sealing requirements are not constant. The best systems balance high magnetic responsiveness, minimal off-state viscosity, excellent particle suspension stability, and robust long-term performance.

The global market for smart fluids is projected to reach $15.8 billion by 2032, with sealing applications representing a rapidly growing segment. Research in Smart Materials and Structures demonstrates that optimized MR seals can achieve pressure differentials exceeding 2 MPa in their activated state while maintaining minimal drag torque when deactivated. Let's examine the key characteristics that define the best magnetorheological fluid sealing systems.

What MR Fluid Formulations Deliver Optimal Sealing Performance?

The performance of an MR sealing system is fundamentally determined by the properties of the MR fluid itself. The ideal formulation provides a strong field-dependent yield stress while maintaining low off-state viscosity and excellent stability.

How Do Carrier Fluid Properties Affect Seal Behavior?

The carrier fluid's primary role is to suspend the magnetic particles while providing lubricity and corrosion protection. Key considerations include:

- Viscosity-Temperature Relationship: Low and stable viscosity across the operating temperature range minimizes off-state (no field) drag and power loss. Silicone oils and synthetic hydrocarbons are common choices.

- Chemical Compatibility: Must not swell or degrade the seal's elastomeric components or the housing materials.

- Volatility and Environmental Stability: Low volatility prevents fluid loss and property change over time; additives may be needed for oxidation resistance.

According to specifications from leading manufacturers like Lord Corporation, modern MR fluids for seals use specially formulated silicone or hydrocarbon oils with viscosity typically between 50-200 cP at 40°C, ensuring smooth operation when the magnetic field is off.

What Particle Characteristics Maximize Magnetic Response?

The magnetic particles are the active element. Optimal particles exhibit:

- High Saturation Magnetization: Typically achieved with high-purity carbonyl iron powder (CIP) or spherical iron particles, enabling strong chain formation under a magnetic field and high yield stress.

- Controlled Size Distribution: Particles in the 1-10 micrometer range are common. A narrow size distribution promotes uniform response and reduces sedimentation.

- Surface Treatment: Coatings (e.g., silica, polymers) prevent aggregation, improve dispersion stability, and reduce wear on sealing surfaces.

Research in the Journal of Intelligent Material Systems and Structures indicates that fluids with 30-40% particle volume fraction can achieve yield stresses of 50-100 kPa under moderate magnetic fields (~0.3 T), which is sufficient for most dynamic sealing applications.

What Magnetic Circuit and Seal Designs Are Most Effective?

The magnetic circuit design dictates how efficiently electrical energy is converted into a magnetic field to activate the MR fluid. The seal geometry determines how the activated fluid interacts with the moving surface to create the barrier.

How is Magnetic Flux Efficiently Directed to the Sealing Gap?

An efficient magnetic circuit concentrates flux across the narrow gap where the MR fluid resides. This is typically achieved with:

- Ferromagnetic Pole Pieces: Made from low-carbon steel or specialized alloys, they guide flux from the coil to the gap.

- Minimized Air Gaps: All non-sealing air gaps in the magnetic path are minimized to reduce magnetic reluctance.

- Coil Optimization: The electromagnetic coil is positioned to maximize flux density in the fluid with minimal power consumption and heat generation.

Finite Element Analysis (FEA) software, like ANSYS Maxwell, is essential for optimizing this design. The best seals achieve flux densities of 0.3-0.8 Tesla in the gap with compact, efficient coils.

What are the Advantages of Multi-Stage and Tapered Gap Designs?

- Multi-Stage Seals: Several sealing gaps in series, each with its own magnetic circuit or sharing a circuit. This dramatically increases the total pressure capacity of the seal, as each stage holds a portion of the pressure drop. It's analogous to multi-stage mechanical seals.

- Tapered or Radial Gap Designs: The gap dimension varies, which can be used to optimize fluid retention, control shear rates, or create a magnetic flux gradient for specialized control.

These advanced geometries allow MR seals to handle very high pressures or provide more nuanced control over leakage rates. They are often used in demanding applications like hydraulic actuators or precision manufacturing equipment.

What Control Systems and Power Management Enable Practical Use?

The intelligence of an MR seal lies in its control system. The ability to precisely modulate the magnetic field—and thus the sealing strength—in real-time is what sets it apart from passive seals.

How Do Closed-Loop Control Systems Enhance Performance?

While simple on/off control is possible, advanced applications use closed-loop feedback for precise regulation. The system might use:

- Pressure Sensors: Upstream and downstream of the seal to measure the pressure differential it is holding.

- Leakage Sensors: To directly monitor flow past the seal.

- Position/Velocity Sensors: For dynamic adjustment based on shaft speed or piston position.

The controller (often a PID algorithm) adjusts the coil current to maintain the desired sealing parameter (e.g., zero leakage, constant back-pressure) despite changes in operating conditions. This is critical for applications like variable-compression engines or adaptive shock absorbers.

How is Power Consumption Minimized for Continuous Operation?

A key advantage of MR seals is that they only require significant power to change their state. To hold a seal against pressure, the magnetic field (and thus the electrical current) must be maintained, which can lead to heating. Strategies to minimize power include:

- Latching Designs: Using permanent magnets in combination with electromagnets. A short current pulse from the electromagnet can "switch" the permanent magnet's field to either reinforce or cancel it, locking the seal in an on or off state with zero holding power.

- Pulse-Width Modulation (PWM): Applying current in high-frequency pulses to reduce average power and heat generation while maintaining the required magnetic field.

- Efficient Magnetic Circuits: As previously mentioned, minimizing reluctance reduces the amp-turns required for a given flux density.

What Are the Key Durability and Reliability Considerations?

For an MR seal to be viable in industrial or medical settings, it must demonstrate long-term reliability, resisting failure modes like particle settling, seal wear, and fluid degradation.

How is Sedimentation and Clogging Prevented?

Sedimentation of heavy iron particles is a primary challenge. Mitigation strategies include:

- Thixotropic Additives: Agents like fumed silica or special clays create a weak gel structure that supports particles when the fluid is static but breaks down under shear, preventing settling without significantly increasing off-state viscosity.

- Continuous Agitation or Circulation: In some systems, a small pump or agitator keeps the fluid homogenous. This adds complexity but is used in critical applications.

- Magnetic Circuit Design: Some designs use a slight permanent magnetic bias to create a very weak holding field that keeps particles suspended without fully activating the fluid.

What Materials and Surface Treatments Minimize Wear?

The interface between the activated MR fluid and the moving shaft (or housing) can experience wear. Solutions include:

- Hard Coatings: Applying wear-resistant coatings like chromium carbide, DLC (Diamond-Like Carbon), or hard anodizing to the mating surfaces.

- Smooth Surface Finishes: Extremely fine surface finishes (e.g., Ra < 0.2 µm) reduce abrasive wear.

- Fluid Additives: Anti-wear additives similar to those in lubricating oils can be incorporated into the carrier fluid.

Accelerated life testing is crucial to validate these choices, often following standards adapted from mechanical seal testing (e.g., API 682).

Conclusion

The best magnetorheological fluid sealing systems are those that integrate a high-performance, stable MR fluid with an efficient and durable electromagnetic-mechanical design, governed by an intelligent control system. They excel in applications requiring adaptive control—where sealing needs change dynamically due to pressure, speed, or operational mode. While they are more complex and costly than passive seals upfront, their value is realized in superior performance, reduced maintenance from wear compensation, and enablement of new adaptive machinery concepts. As material science improves fluid stability and compact, efficient magnetic designs become more common, MR seals are poised to move from niche high-performance applications into broader industrial use.

Ready to explore whether magnetorheological sealing technology can solve your dynamic sealing challenges? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss your application requirements and explore potential design solutions.