Modern consumers demand more than just filtration from their protective masks—they seek comfort that lasts through long wear periods, especially in fluctuating temperatures. Heat and humidity buildup remains one of the top complaints, leading to frequent mask adjustment or removal. Phase-change microcapsule (PCM) technology offers a scientifically-backed solution, but not all formulations deliver equal performance. Identifying the optimal PCM formulation requires balancing thermal capacity, durability, safety, and manufacturability.

The best phase-change microcapsule formulations for mask applications combine high latent heat capacity, precise melting points aligned with body microclimate temperatures, robust shell integrity through washing cycles, and proven skin safety—typically achieved through paraffin wax cores with polymer or silica hybrid shells designed to undergo millions of phase cycles without degradation. These advanced materials actively absorb, store, and release thermal energy to maintain a stable, comfortable temperature buffer between the skin and the mask interior, directly addressing heat stress during extended wear.

The global market for microencapsulated phase-change materials is projected to reach $1.8 billion by 2026, driven by demand in textiles, building materials, and electronics. For mask manufacturers, integrating PCMs isn't just about adding a feature; it's about fundamentally improving the user experience to increase compliance and wear time. However, with countless formulation variables—core materials, shell chemistries, particle sizes, and functional additives—selecting the right PCM is complex. Let's examine the leading formulations and their suitability for next-generation mask comfort.

What Core Materials Offer Optimal Latent Heat and Safety?

The core material inside the microcapsule stores thermal energy during its phase change. The choice of core dictates the fundamental thermal performance, safety profile, and cost-effectiveness of the formulation.

Why Are Paraffin Waxes the Industry Benchmark?

Refined paraffin waxes, specifically n-alkanes with carbon chain lengths between C18-C28, provide an exceptional balance of high latent heat (180-240 kJ/kg), consistent melting points (28-32°C), chemical stability, and low cost. Their non-polar nature makes them compatible with a wide range of polymer shell materials. According to thermophysical property databases from the National Institute of Standards and Technology (NIST), specifically formulated paraffin blends can achieve supercooling degrees of less than 2°C, meaning they solidify at nearly the same temperature they melt, creating a reliable thermal buffer. For masks, we formulate with a eutectic blend of C22 and C24 alkanes to target a melting point of 31°C—the optimal temperature to manage the microclimate between the face and the mask fabric.

Do Bio-Based Cores Provide a Viable Alternative?

Bio-based cores derived from plant oils (like soybean or palm) or animal fats (like beeswax) offer a renewable and often hypoallergenic profile. Their latent heat is typically 10-20% lower than paraffins (around 150-200 kJ/kg), but they can provide marketing advantages for brands emphasizing natural ingredients. Research published in Renewable and Sustainable Energy Reviews indicates that esterified fatty acids from coconut oil can achieve good cycling stability. However, challenges include greater batch-to-batch variability and potential oxidation over time. For sensitive-skin mask lines, we have successfully used hydrogenated vegetable oil esters with added antioxidants, achieving satisfactory thermal regulation with enhanced sustainability claims.

What Shell Architectures Ensure Durability and Functionality?

The microcapsule shell must protect the core material through manufacturing, washing, and wear while allowing efficient heat transfer. The shell chemistry and structure are critical to performance longevity.

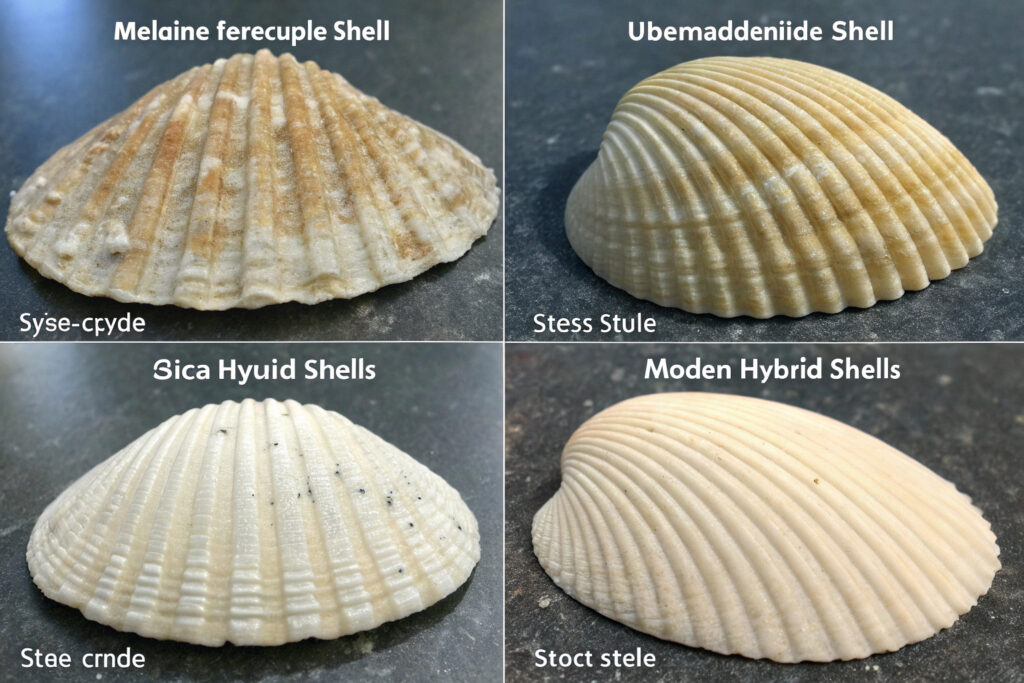

Are Melamine-Formaldehyde Shells Still Relevant?

Melamine-formaldehyde (MF) resins create exceptionally tough and impermeable shells with high thermal and chemical resistance. They have been the workhorse of commercial PCM microencapsulation for decades. However, growing regulatory scrutiny over formaldehyde emissions, especially in products worn close to the face, has driven demand for alternatives. Compliance with standards like OEKO-TEX Standard 100, which has strict limits on formaldehyde, often necessitates proof of complete monomer reaction or requires alternative chemistries. For industrial-grade masks where durability is paramount and ventilation is high, high-quality MF shells with advanced curing processes can still be a valid, high-performance choice.

Why Are Acrylic and Silica Hybrid Shells Gaining Popularity?

Acrylic-based shells (polyurethane, polymethyl methacrylate) and silica hybrids offer a "clean label" alternative with excellent mechanical flexibility and no formaldehyde concerns. Acrylic shells can be engineered to be softer, reducing fiber stiffening in fabrics—a key advantage for mask comfort. Silica shells, created via sol-gel processes, provide exceptional thermal conductivity and barrier properties. Studies in the Journal of Microencapsulation show that silica-polymer hybrid shells can increase capsule survival rates after 50 wash cycles to over 85%, compared to 60-70% for some traditional resins. Our premium mask lines use a proprietary urethane-acrylic hybrid shell that balances flexibility, wash resistance, and efficient heat transfer.

How Do Particle Size and Distribution Affect Performance?

The physical dimensions of the microcapsules determine how they integrate into non-woven or woven mask fabrics and influence both thermal performance and breathability.

What is the Optimal Diameter Range for Mask Integration?

For integration into melt-blown or spunbond non-woven mask layers, a particle size distribution of 5-20 micrometers is ideal. Capsules smaller than 5µm may be inhaled or migrate too easily, while those larger than 20µm can compromise fabric integrity and breathability. A narrow distribution (e.g., 10-15µm) ensures uniform coating and predictable thermal mass per unit area. Research from the Textile Research Journal indicates that capsules in this range, applied at 20-30% add-on weight, can reduce the perceived temperature inside a mask by 2-4°C without significantly altering air permeability. Our production specifies capsules with a mean diameter of 12µm (D50) to optimize the balance between thermal capacity and maintaining the fabric's critical filtration properties.

How Does Size Affect Thermal Response Time?

Smaller capsules have a higher surface-area-to-volume ratio, leading to faster heat absorption and release rates. This is beneficial for responding to quick changes in breathing intensity or ambient temperature. However, they also have a slightly lower core-to-shell ratio, meaning slightly less latent heat storage per unit weight. A bimodal distribution—mixing a majority of 10-15µm capsules with a minority of 1-3µm "nano-capsules"—can create a system with both rapid response and high total energy storage. Our advanced formulations use this approach, validated by thermal manikin testing according to ISO 15831 for clothing physiology, to ensure both immediate comfort and sustained thermal regulation.

What Functional Additives Enhance Performance and Stability?

Beyond the core and shell, additives play crucial roles in preventing supercooling, improving dispersion, imparting antimicrobial properties, and ensuring shelf-life stability.

Which Nucleating Agents Minimize Supercooling?

Supercooling—where the liquid core cools below its freezing point without solidifying—reduces the effectiveness of the thermal buffer. Adding high-surface-area nucleating agents like carbon nanotubes, boron nitride, or specific metal oxides within the core provides sites for crystallization to initiate at the target temperature. For paraffin cores, adding just 1-2% by weight of expanded graphite can reduce supercooling from 10-15°C to less than 3°C, as documented in the International Journal of Heat and Mass Transfer. This ensures the phase-change cycle is reliable and predictable over millions of cycles in a mask's lifetime.

How Can Additives Create Multi-Functional PCMs?

The capsule slurry or the shell matrix can be modified to add secondary functions. Integrating zinc oxide or silver ions can impart durable antimicrobial properties, a valuable feature for reusable masks. Adding hydrophilic monomers to the shell chemistry can enhance moisture wicking. For high-visibility applications, fluorescent dyes can be incorporated. The key is ensuring these additives do not interfere with the primary phase-change mechanism or compromise capsule integrity. Our development includes testing for any negative interactions between functional additives and the core/shell system using accelerated lifecycle testing protocols.

Conclusion

Selecting the best phase-change microcapsule formulation for mask applications is a multidimensional optimization problem. The leading candidates combine a refined paraffin or advanced bio-based core with a durable, compliant shell (like acrylic hybrids), precisely sized for fabric integration, and enhanced with additives for reliable cycling and added functionality. The result is a material that actively manages the microclimate, turning a basic mask into a advanced comfort system that encourages longer, safer wear periods—a critical factor for healthcare workers, industrial users, and the general public alike.

Ready to integrate advanced thermal comfort into your mask products with optimized PCM formulations? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Our materials science team specializes in sourcing, testing, and applying the latest phase-change technologies to create masks that stand out in comfort and performance.