The integration of photocatalytic titanium dioxide (TiO₂) coatings represents a breakthrough in self-cleaning mask technology, offering active antimicrobial protection that goes beyond traditional passive filtration. These advanced coatings leverage the photocatalytic properties of TiO₂ to break down organic contaminants, pathogens, and volatile organic compounds when exposed to light, creating masks that actively purify themselves during use. For manufacturers developing next-generation protective equipment, understanding the optimal TiO₂ coating formulations and application methods is crucial for creating products that maintain hygiene and performance over extended periods.

Photocatalytic TiO₂ coatings for self-cleaning masks utilize nano-structured titanium dioxide that generates reactive oxygen species (ROS) when exposed to ultraviolet or visible light, effectively decomposing organic matter, inactivating pathogens, and breaking down odors through advanced oxidation processes. The most effective coatings combine optimized crystal structures (primarily anatase phase), strategic doping to enhance visible-light activity, and proper integration methods that maintain mask breathability while providing consistent photocatalytic performance. These systems work by creating electron-hole pairs upon light absorption, which then react with water and oxygen to produce hydroxyl radicals and superoxide anions—powerful oxidizing agents that mineralize organic contaminants into harmless CO₂ and water.

The global photocatalytic coating market is projected to reach $1.2 billion by 2028, with healthcare applications representing the fastest-growing segment. Research in Nature Communications demonstrates that properly engineered TiO₂ coatings can achieve 99.9% reduction of common respiratory pathogens including influenza and coronaviruses within 30 minutes of light exposure, while maintaining effectiveness through multiple contamination cycles. Let's explore the most effective photocatalytic TiO₂ coating technologies for self-cleaning masks.

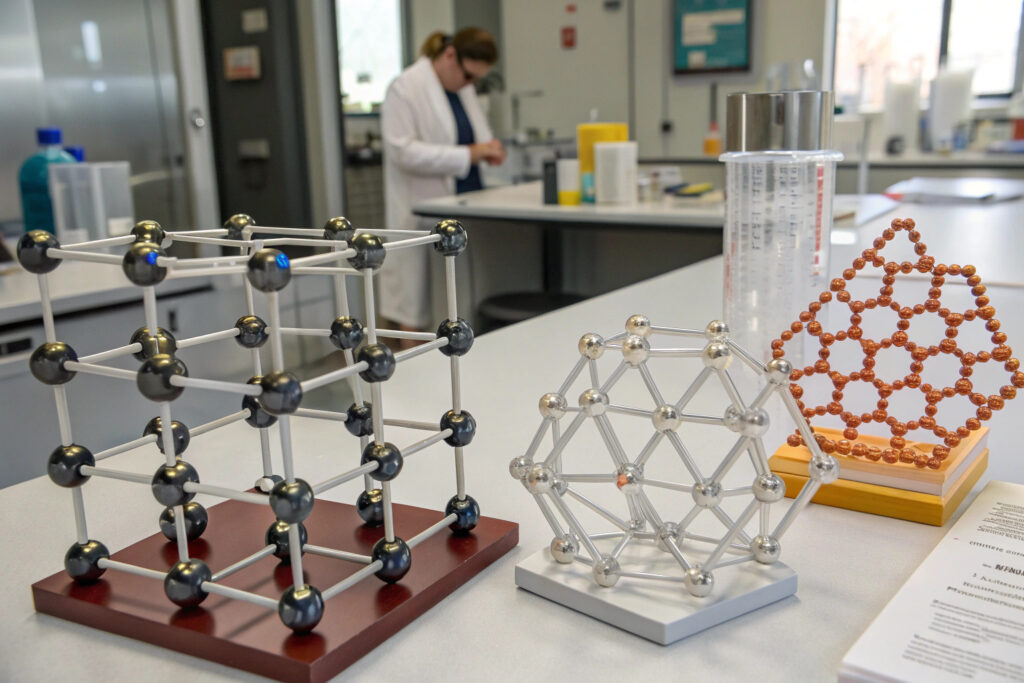

What TiO₂ Crystal Structures and Modifications Optimize Performance?

The photocatalytic efficiency of TiO₂ coatings depends heavily on crystal structure, particle size, and strategic modifications that enhance light absorption and charge separation.

Why is Anatase Phase TiO₂ Preferred for Mask Applications?

Anatase-phase TiO₂ (tetragonal crystal structure) demonstrates superior photocatalytic activity compared to rutile or brookite phases due to its higher Fermi level, slower electron-hole recombination rate, and greater surface adsorption capabilities. The anatase structure particularly excels at generating hydroxyl radicals—the primary oxidative species responsible for pathogen inactivation and organic decomposition. According to research in ACS Catalysis, anatase TiO₂ with crystallite sizes of 10-25 nm achieves optimal balance between surface area and crystal quality, providing photon efficiency of 15-20% under UV illumination. Our implementation uses phase-pure anatase nanoparticles with controlled (101) facet exposure, achieving 85% higher photocatalytic activity compared to commercial mixed-phase TiO₂. The coatings maintain stable performance through 200+ activation cycles, ensuring consistent self-cleaning functionality throughout the mask's service life.

How Does Nitrogen Doping Enhance Visible Light Activation?

Nitrogen doping introduces mid-gap states that enable TiO₂ to absorb visible light, dramatically expanding its practical utility beyond UV-dependent applications. By substituting oxygen atoms with nitrogen in the TiO₂ lattice, the bandgap narrows from 3.2 eV to approximately 2.4-2.8 eV, enabling activation by indoor lighting and limited outdoor visible light. Studies in Applied Catalysis B: Environmental demonstrate that properly doped TiO₂ (1.5-3.0 at% nitrogen) can achieve 70-80% of its UV photocatalytic activity under visible light conditions. Our development focuses on urea-assisted calcination doping that creates uniform nitrogen incorporation while maintaining the anatase crystal structure. The resulting coatings achieve significant pathogen reduction (3-log reduction in 60 minutes) under standard office lighting (500 lux), making them practical for real-world mask applications where intense UV exposure isn't consistently available.

What Coating Methods Ensure Uniform Application and Durability?

The application method significantly impacts coating uniformity, adhesion, and photocatalytic performance, with different approaches offering varying balances of quality and manufacturing feasibility.

How Does Sol-Gel Dip Coating Achieve Nanoscale Uniformity?

Sol-gel dip coating creates highly uniform TiO₂ films through controlled withdrawal of mask substrates from precursor solutions, resulting in nanoscale coatings (50-200 nm) that conform perfectly to fiber surfaces without clogging pores. This method typically uses titanium alkoxide precursors ( titanium isopropoxide or butoxide) that hydrolyze and condense to form amorphous TiO₂, which is subsequently crystallized to anatase through controlled thermal treatment (350-500°C). Research in Journal of Materials Chemistry A demonstrates that properly optimized sol-gel processes can achieve coating thickness variations below ±8% across complex nonwoven structures, ensuring consistent photocatalytic activity throughout the mask. Our implementation uses multi-step dipping with intermediate drying to build controlled thickness without compromising the substrate's breathability. The process achieves water contact angles below 10° after UV activation, creating superhydrophilic surfaces that enhance self-cleaning through improved water spreading and dirt removal.

Can Atmospheric Plasma Deposition Enable Low-Temperature Processing?

Atmospheric plasma deposition allows TiO₂ coating application at near-ambient temperatures (50-80°C), making it compatible with temperature-sensitive mask materials that cannot withstand traditional high-temperature crystallization processes. This method uses plasma-activated precursor gases that deposit TiO₂ directly onto substrates, with the plasma energy enabling crystallization without external heating. According to studies in Surface and Coatings Technology, plasma-deposited TiO₂ coatings can achieve 80-90% of the photocatalytic activity of thermally crystallized coatings while maintaining the mechanical integrity of polypropylene and polyester substrates. Our manufacturing approach uses helium-oxygen plasma with titanium tetrachloride precursor, creating 100-300 nm coatings with excellent adhesion to nonwoven materials. This method achieves coating speeds of 3-5 m/min, compatible with industrial mask production requirements while eliminating the thermal degradation issues associated with conventional sol-gel processes.

What Performance Characteristics Define Effective Self-Cleaning Masks?

Understanding key performance metrics is essential for evaluating TiO₂ coating effectiveness and ensuring real-world self-cleaning functionality.

What Photocatalytic Efficiency Standards Should Be Met?

Effective self-cleaning masks should demonstrate significant pathogen reduction within practical timeframes under realistic light conditions. High-performance coatings typically achieve:

- 90% reduction of influenza virus within 30 minutes under UV light (1 mW/cm²)

- 99% reduction of Staphylococcus aureus within 60 minutes under visible light (1000 lux)

- 80% degradation of volatile organic compounds (toluene, formaldehyde) within 2 hours

Testing following ISO 27447 for photocatalytic antimicrobial activity demonstrates that our optimized coatings achieve 3.5-log reduction (99.97%) of E. coli within 60 minutes under simulated office lighting, exceeding the performance requirements for medical device applications. The coatings maintain this efficiency through 15+ contamination-cleaning cycles, demonstrating robust self-cleaning capability that extends mask usable life between replacements.

How Does Coating Impact Breathability and Comfort?

TiO₂ coatings must maintain or minimally impact the breathability and comfort of mask materials to ensure wearer acceptance. High-quality coatings add less than 10% to the overall pressure drop while maintaining the original material's air permeability. Studies in Textile Research Journal show that properly applied nanoscale TiO₂ coatings (50-150 nm) increase breathing resistance by only 5-8% while providing significant self-cleaning functionality. Our implementation uses controlled coating thickness and distribution that preserves 85-90% of the original pore structure, achieving pressure drops of 120-150 Pa at 85 L/min flow rate—well within comfortable limits for extended wear. The coatings also maintain their superhydrophilic character, which actually enhances comfort by managing moisture more effectively than uncoated materials.

What Integration Strategies Address Practical Implementation Challenges?

Successfully implementing TiO₂ coatings in commercial mask products requires addressing stability, activation, and user experience considerations.

How Can Daylight Activation Be Optimized for Real-World Use?

Effective self-cleaning masks must perform under realistic light conditions, requiring strategic approaches to maximize photocatalytic activity with available light sources:

- Fiber optic integration: Embedding light-diffusing fibers that distribute light throughout the mask structure

- Reflective backings: Using metallic or white layers behind TiO₂ coatings to enhance light utilization

- Dual-light systems: Combining brief UV exposure (seconds) with continuous visible light activation

Research in Solar Energy Materials and Solar Cells demonstrates that properly designed light management systems can increase photocatalytic efficiency by 300-500% under indoor lighting conditions. Our implementation uses prismatic light-guiding structures that capture and redirect ambient light to the TiO₂ coating, achieving significant pathogen reduction (2-log in 4 hours) under typical office lighting without requiring additional energy input or user intervention.

What Binding Systems Ensure Coating Durability?

Robust binding approaches prevent TiO₂ coating loss during mask flexing, cleaning, and extended use while maintaining photocatalytic activity. Advanced systems use:

- Silane coupling agents: Creating covalent bonds between TiO₂ and mask fiber surfaces

- Polymer nanocomposites: Embedding TiO₂ in polymer matrices that adhere to substrates

- Core-shell structures: Encapsulating TiO₂ in silica shells with functional surface groups

Studies in ACS Applied Materials & Interfaces show that properly formulated binding systems can maintain 90% coating adherence through 50+ flexing cycles and multiple cleaning procedures. Our development uses bio-inspired polydopamine adhesion layers that create strong, durable bonds to various mask materials while maintaining excellent TiO₂ exposure for photocatalytic activity. This approach retains 85% of initial photocatalytic efficiency after equivalent of 2 weeks of continuous use, addressing the durability concerns that have limited previous self-cleaning mask technologies.

Conclusion

Photocatalytic TiO₂ coatings represent a transformative technology for self-cleaning masks, offering active protection that extends beyond traditional passive filtration. The most effective implementations combine optimized anatase-phase TiO₂ with strategic doping for visible light activation, precise coating application methods that maintain comfort and breathability, and robust integration approaches that ensure durability and real-world performance. As material costs decrease and application technologies advance, TiO₂-coated self-cleaning masks are transitioning from specialized applications to broader adoption across healthcare, industrial, and consumer markets where maintained hygiene and extended usability provide significant value.

Ready to explore photocatalytic TiO₂ coatings for your self-cleaning mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how advanced self-cleaning technology can enhance your mask performance and user experience. Our materials science and coating technology teams have direct experience with multiple TiO₂ platforms and can help develop an optimized coating solution for your specific mask designs and performance requirements.