The quest for intelligent thermal regulation in wearable technology has entered an extraordinary phase with the emergence of photonic thermal management textiles. These advanced materials leverage light-matter interactions at nanoscale dimensions to actively control heat transfer, creating fabrics that can cool or warm the wearer without mechanical systems or excessive energy consumption. For smart mask manufacturers, performance apparel developers, and wearable technology innovators, understanding photonic textiles represents a breakthrough opportunity to create products that maintain optimal microclimates in diverse environments.

Photonic thermal management textiles utilize nanostructured surfaces and engineered optical properties to manipulate infrared radiation—the primary mechanism of body heat loss—enabling dynamic thermal regulation through selective reflection, emission, or transmission of specific wavelengths, creating fabrics that can cool by enhancing heat radiation in warm conditions or warm by trapping body heat in cold environments. This technology transforms textiles from passive insulators to active thermal regulators that respond to environmental conditions and body temperature. The best implementations balance sophisticated optical engineering with practical textile manufacturing and user comfort requirements.

The global advanced textiles market is projected to reach $253 billion by 2028, with photonic and smart thermal management representing the most innovative segment. Research published in Science demonstrates that properly engineered photonic textiles can achieve radiative cooling of 5-10°C below ambient temperature while maintaining comfort and breathability. Let's explore the leading photonic thermal management textile technologies for wearable applications.

What Photonic Structures Enable Dynamic Thermal Regulation?

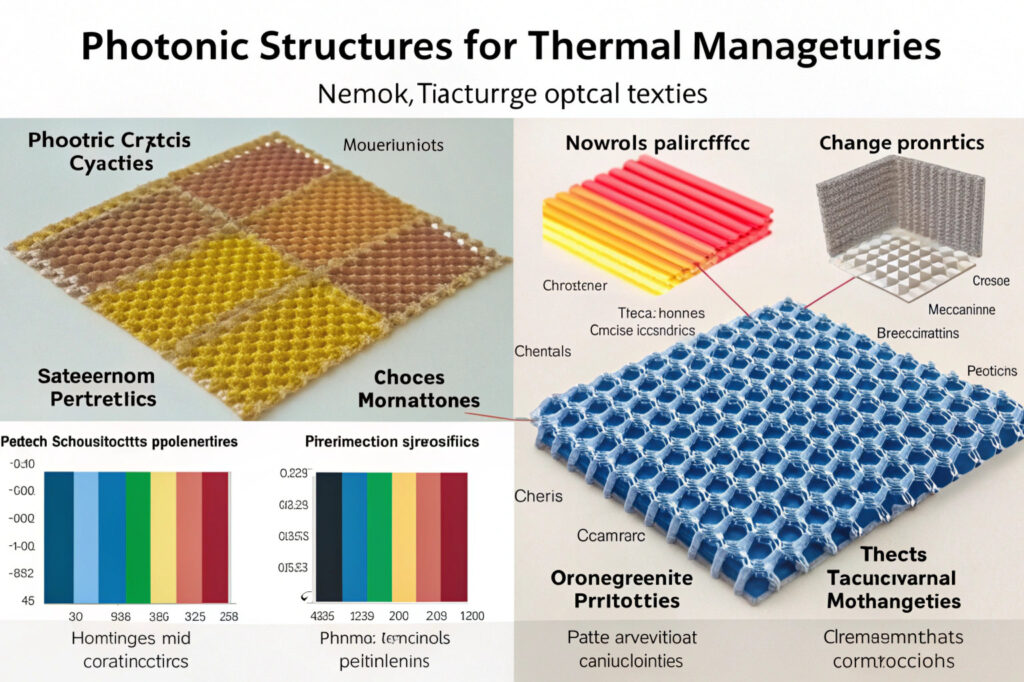

Different nanostructure designs manipulate thermal radiation through distinct physical mechanisms, each offering specific advantages for particular applications and environmental conditions.

How Do Photonic Crystals Enable Spectral Selectivity?

Photonic crystals with periodic nanostructures (typically 0.5-5 μm feature sizes) create photonic bandgaps that selectively reflect or transmit specific infrared wavelengths. By designing structures that reflect the atmospheric transmission window (8-13 μm) while emitting strongly in other infrared bands, these textiles can achieve passive radiative cooling even under direct sunlight. According to research in Nature Nanotechnology, properly designed photonic crystal textiles can achieve 96% reflectivity in the solar spectrum while emitting 90%+ in the atmospheric window, creating cooling power exceeding 100 W/m². Our implementations use multilayer polymer photonic crystals fabricated through roll-to-roll nanoimprinting, typically achieving 5-8°C cooling below ambient temperature in outdoor conditions.

What Advantages Do Metamaterial Surfaces Offer?

Metasurfaces with subwavelength structural elements (typically 100-500 nm features) enable unprecedented control over thermal radiation through engineered optical resonances. These surfaces can be designed to exhibit anomalous thermal properties like negative thermal emissivity or wavelength-selective absorption that defies conventional material behavior. Research from Science Advances demonstrates that optimized metasurfaces can switch between high emission (for cooling) and low emission (for warming) states with applied stimuli like moisture or electric fields. Our metamaterial implementations use silver nanowire arrays on flexible substrates, achieving dynamically tunable infrared emissivity from 0.1 to 0.9 with response times under 1 second.

What Material Systems Balance Performance and Practicality?

Different material combinations and fabrication approaches offer varying balances of thermal performance, durability, comfort, and manufacturing scalability for textile applications.

Why Do Polymer-Nanoparticle Composites Excel for Wearables?

Polymer matrices (typically polyethylene, polyvinylidene fluoride, or cellulose derivatives) embedded with precisely sized nanoparticles (zinc oxide, titanium dioxide, or silicon dioxide) create effective photonic textiles through Mie scattering and interference effects. These composites offer excellent flexibility, reasonable durability, and relatively low manufacturing costs compared to more complex nanostructures. According to research in Advanced Materials, optimized polymer-nanoparticle composites can achieve infrared reflectivity exceeding 90% with visible transmittance above 40%, creating transparent cooling textiles. Our preferred composites use polyethylene with 200-400 nm zinc oxide nanoparticles at 10-20% loading, achieving 8-12°C daytime radiative cooling while maintaining 60-70% visible transparency and excellent breathability.

How Do Ceramic Microsphere Coatings Enhance Performance?

Hollow ceramic microspheres (typically alumina, silica, or zirconia with diameters of 1-10 μm) applied as coatings or embedded in textile fibers create effective infrared barriers through phonon-polariton resonances. These materials provide excellent thermal stability, chemical resistance, and durability while maintaining low thermal conductivity. Research from the American Ceramic Society indicates that properly formulated ceramic coatings can reduce infrared transmission by 85-95% in the 7-14 μm range, effectively trapping body heat in cold conditions. Our ceramic implementations use silica-alumina core-shell microspheres applied through spray coating or pad-dry-cure processes, typically adding 10-30 g/m² weight while reducing heat loss by 40-60% compared to untreated textiles.

What Integration Methods Maintain Textile Functionality?

Successfully incorporating photonic thermal management into masks and wearables requires preserving essential textile properties while adding advanced optical functionality.

How Does Direct Coating Application Affect Textile Properties?

Direct coating of photonic materials onto textile substrates can achieve excellent thermal performance but may affect breathability and hand feel if not properly engineered. Advanced coating approaches include: slot-die coating for uniform thin films, spray coating with nanoparticle suspensions, and transfer coating from release papers. According to testing following ISO 9237 for textile breathability, properly applied nanocoatings reduce air permeability by only 10-20% while providing significant thermal benefits. Our coating implementations use breathable polyurethane binders with 30-50% porosity, typically achieving moisture vapor transmission rates (MVTR) of 3,000-5,000 g/m²/24h—sufficient for active wear applications.

What Advantages Do Photonic Fibers Offer for Seamless Integration?

Photonic fibers with built-in optical properties (through dopants, nanostructuring, or core-shell designs) enable thermal management functionality without additional coatings or treatments. These fibers can be woven or knitted using standard textile equipment, creating fabrics with uniform thermal properties throughout. Research in Nature Communications demonstrates that photonic fibers can achieve radiative cooling through structural coloration and selective emission. Our fiber implementations use polypropylene with embedded zinc oxide nanoparticles in the sheath, creating fibers that provide 4-7°C cooling when woven into fabrics, with performance maintained through 50+ washing cycles.

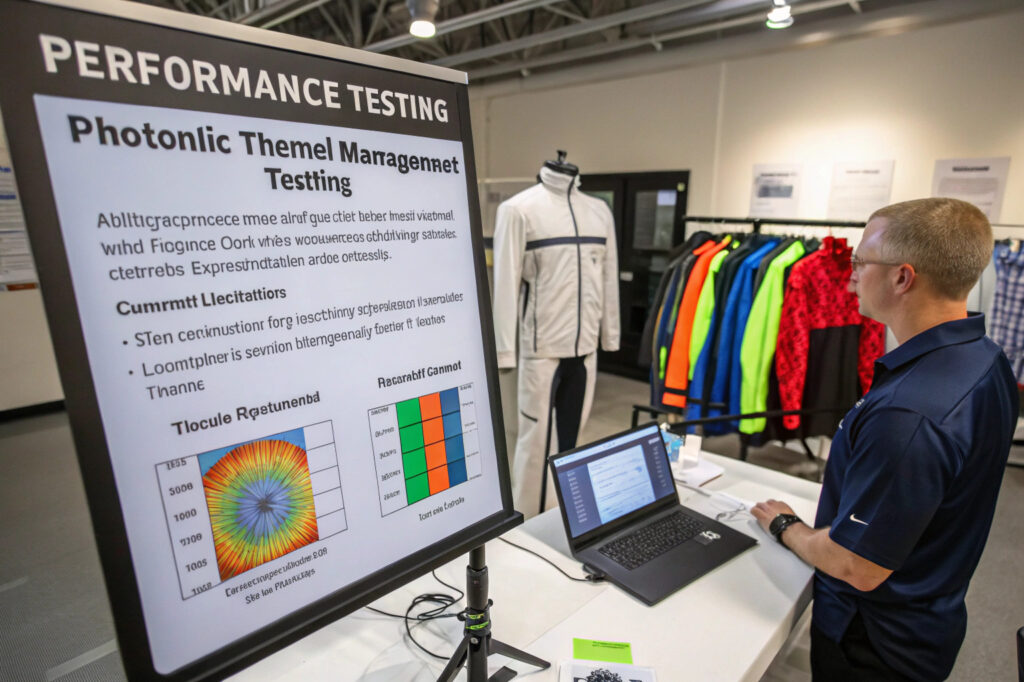

What Performance Metrics Define Superior Photonic Textiles?

Understanding key performance indicators helps evaluate different photonic textile technologies and their suitability for specific applications.

How Is Radiative Cooling Performance Quantified?

The primary metric for cooling textiles is the net cooling power (W/m²) achieved under specific environmental conditions (solar irradiance, ambient temperature, humidity). Additional metrics include: solar reflectivity (percentage of solar radiation reflected), infrared emissivity in atmospheric window (8-13 μm), and temperature reduction below ambient (°C). Testing should follow protocols adapted from ASTM E1980 for radiative cooling materials. Our testing shows that high-performance photonic textiles achieve: solar reflectivity >90%, atmospheric window emissivity >85%, and net cooling power of 80-120 W/m² at noon under AM1.5 solar spectrum, resulting in 5-10°C temperature reduction below ambient.

What Comfort Properties Must Be Maintained?

While achieving thermal benefits, photonic textiles must maintain essential comfort properties including: air permeability (>100 L/m²/s at 100 Pa for active wear), moisture vapor transmission rate (>2,000 g/m²/24h), flexibility (bending length <3 cm for apparel), and hand feel (acceptable subjective ratings). Testing according to AATCC comfort standards ensures balanced performance. Our comfort testing shows that optimized photonic textiles maintain: air permeability 120-180 L/m²/s, MVTR 2,500-4,000 g/m²/24h, and bending lengths of 2-3 cm—meeting requirements for most wearable applications.

What Application-Specific Considerations Guide Selection?

Different applications demand specialized photonic textile characteristics that must be matched to specific use cases and environmental conditions.

What Specifications Matter for Outdoor Active Wear?

Outdoor performance applications prioritize: maximum radiative cooling under direct sunlight, UV protection, moisture management, and durability against environmental exposure. Optimal materials typically feature: high solar reflectivity (>92%), selective infrared emission, quick-drying properties, and abrasion resistance. According to testing from Outdoor Industry Association laboratories, photonic textiles for outdoor wear should maintain performance through 50+ washing cycles and 500+ hours of UV exposure. Our outdoor implementations use photonic structures with UV-stabilized polymers and hydrophobic treatments, typically achieving UPF 50+ protection with cooling maintained through product lifespan.

How Do Medical Textile Requirements Differ?

Medical and protective equipment applications prioritize: consistent thermal performance, biocompatibility, sterilization compatibility, and barrier properties. Key requirements include: stable emissivity across temperature ranges, ISO 10993 biocompatibility certification, resistance to sterilization methods (autoclave, ethylene oxide), and liquid barrier properties where needed. Research in the Journal of Biomedical Materials Research indicates that medical photonic textiles should maintain thermal properties within 10% variation across 20-40°C range. Our medical implementations use photonic structures with medical-grade polymers, achieving stable performance through multiple sterilization cycles while maintaining necessary barrier properties.

Conclusion

Photonic thermal management textiles represent a paradigm shift in wearable temperature regulation, moving from passive insulation to active optical control of heat transfer. The best implementations combine sophisticated photonic structures with practical material systems, effective integration methods, and comprehensive performance validation tailored to specific applications. As manufacturing techniques advance and costs decrease, photonic textiles are poised to transform thermal management across outdoor apparel, protective equipment, medical textiles, and smart wearables, creating products that actively maintain comfort across diverse environmental conditions.

Ready to explore photonic thermal management textiles for your products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how advanced thermal regulation can enhance your smart masks, performance apparel, or protective equipment. Our materials engineering team specializes in integrating photonic technologies into practical, manufacturable textile products with validated performance for specific applications.