The evolution of smart textiles has moved beyond basic connectivity to address one of the most critical challenges in wearable technology: ensuring optimal fit and continuous monitoring of garment-skin interface conditions. Piezoresistive fit-sensing smart textiles represent a transformative approach, enabling real-time, distributed measurement of pressure, stretch, and contact quality without rigid sensors or complex wiring. For manufacturers of performance wear, medical devices, and advanced protective equipment like masks, understanding these intelligent textiles is key to developing products that actively ensure proper fit and user comfort.

Piezoresistive fit-sensing smart textiles are fabric-based sensor systems whose electrical resistance changes predictably when stretched, compressed, or bent, allowing them to map pressure distribution and detect gaps or improper fit across a garment's entire surface through integrated conductive pathways. These systems transform ordinary textiles into distributed sensing networks that can provide quantitative fit data, alert users to readjustment needs, and even enable adaptive tightening or loosening. The best implementations balance high sensitivity, minimal hysteresis, wash durability, and seamless integration into wearable products.

The global smart textiles market is projected to reach $11.6 billion by 2028, with sensing applications driving significant growth. Research in Advanced Materials Technologies demonstrates that optimized piezoresistive textiles can detect pressure changes as subtle as 0.5 kPa with response times under 100 milliseconds—sufficient for monitoring mask seal integrity during normal movement and speech. For applications where fit directly correlates with protection or performance, these textiles offer unprecedented capabilities. Let's examine the characteristics that define the best piezoresistive fit-sensing systems.

What Material Compositions Deliver Optimal Sensing Performance?

The sensing capability of piezoresistive textiles depends fundamentally on the conductive materials and their integration with flexible substrates. Different material systems offer distinct advantages in sensitivity, range, and durability.

How Do Carbon-Based Composites Compare to Metallic Systems?

- Carbon-Based Composites (Carbon Black, CNTs, Graphene): These are dispersed within an elastic polymer matrix (e.g., silicone, polyurethane, thermoplastic elastomer) and coated onto or embedded in textiles. Their piezoresistive effect comes from the changing contact points between conductive particles as the matrix deforms.

- Advantages: Excellent flexibility, wide resistance range, lower cost, and good chemical stability.

- Disadvantages: Can exhibit significant hysteresis (the resistance doesn't return exactly to its original value after strain), and sensitivity may degrade with large, repeated deformations.

- Metallic Systems (Silver Nanowires, Flakes): These form percolation networks on fiber surfaces. Stretching the textile separates the nanowires, increasing resistance.

- Advantages: Very high initial conductivity, often lower hysteresis, and potentially better long-term stability under small, repetitive strains.

- Disadvantages: Higher cost, and metallic networks can crack under high elongation, leading to irreversible resistance changes.

For fit-sensing in masks, where strains are moderate (typically) but repetitive, hybrid systems often perform best. For example, a graphene-silver nanowire hybrid ink can offer the high sensitivity of graphene with the stability of a metallic network. Research from organizations like the Institute for Soldier Nanotechnologies highlights such hybrids for wearable sensing.

What is the Role of Intrinsic Conductive Polymers?

Polymers like PEDOT:PSS are conductive in their own right and can be applied as a coating. Their resistance changes as the polymer chains align or separate under strain. They are highly biocompatible and can be made transparent, but their conductivity is generally lower than metal-based systems, and environmental stability (especially to humidity) can be a challenge. They are excellent for applications where skin contact and comfort are paramount, and very high sensitivity isn't required.

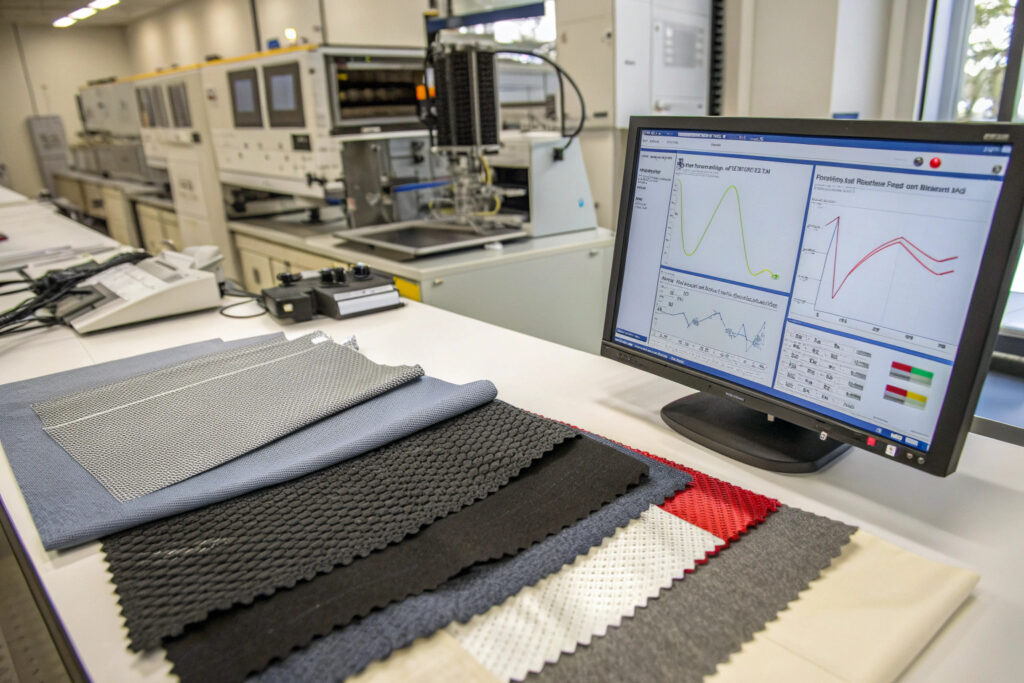

What Fabric Structures and Integration Methods Are Most Effective?

The textile's base structure and how the sensing element is integrated determine comfort, durability, and how accurately the sensor measures fit-related forces.

How are Sensing Grids or Arrays Woven or Knitted into Fabric?

The most elegant integration creates the sensor directly during fabric formation. Conductive yarns (e.g., silver-plated nylon, stainless steel fiber blends) are used as warp or weft threads in a weaving loom or are knitted in specific patterns.

- Woven Grids: Conductive yarns can be spaced to create a Cartesian (X-Y) grid. Where they intersect, they form a pressure-sensitive junction. By scanning rows and columns, a pressure map can be created.

- Knit Structures: The looped structure of knits inherently provides stretch. Integrating conductive yarns in certain courses (rows) can create sensors that respond specifically to stretch in the direction of the course.

This method produces highly durable and flexible sensors that are part of the fabric's structure. However, design changes require re-tooling the weaving/knitting process, and the resolution of the sensing grid is limited by yarn thickness.

What are the Advantages of Coating and Printing Techniques?

- Screen/Inkjet Printing: Conductive inks are printed onto a pre-made, stretchy fabric substrate (e.g., nylon-spandex, polyester-elastane). This allows for:

- High Design Flexibility: Complex circuit patterns, different sensor shapes (dots, lines, arcs), and high spatial resolution can be achieved easily.

- Rapid Prototyping: Designs can be changed digitally without altering the base fabric.

- Transfer Coating/Lamination: A pre-made film of piezoresistive composite is thermally or adhesively laminated onto the fabric.

The key challenge is ensuring the coating/film can withstand the repeated stretching of the textile without cracking or delaminating. Using an intermediate adhesive or encapsulation layer with matched elasticity is crucial. For mask fit sensors, printing specific patterns on the inner seal area is often the most practical approach.

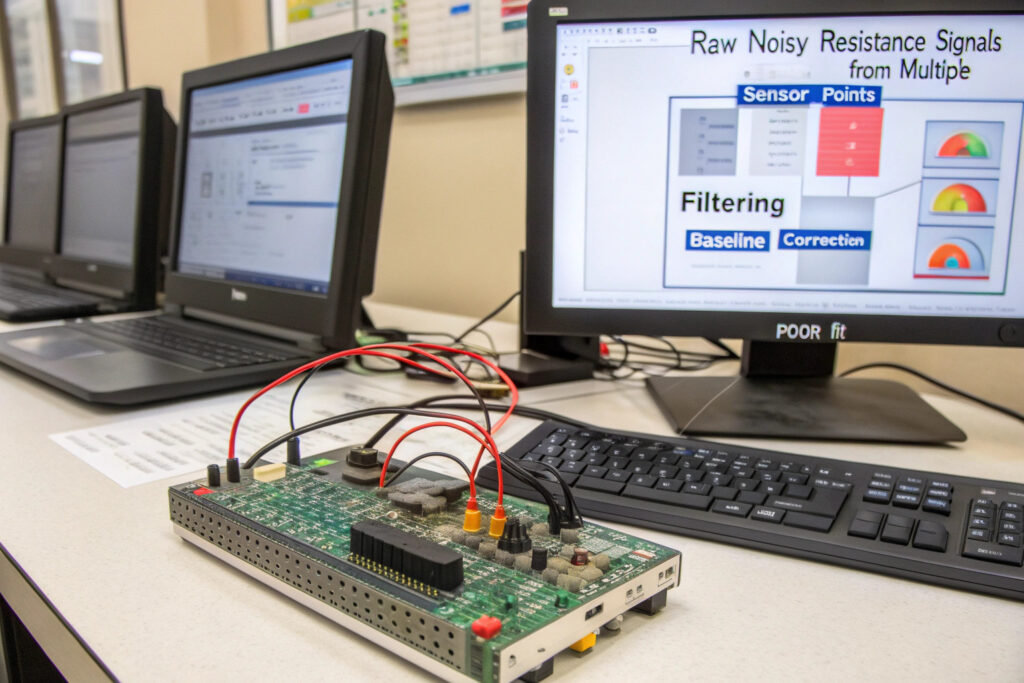

What Signal Processing and Interpretation Methods Are Needed?

Raw resistance data from a textile is noisy and needs sophisticated processing to translate into meaningful "fit" information.

How is Baseline Drift and Hysteresis Compensated For?

Piezoresistive materials, especially elastomeric composites, exhibit:

- Baseline Drift: The resting resistance slowly changes over time due to material creep or temperature.

- Hysteresis: The resistance during loading (applying pressure) differs from during unloading at the same pressure level.

Advanced compensation algorithms are required: - Adaptive Baseline Tracking: The system continuously updates what it considers the "zero pressure" resistance for each sensor node.

- Hysteresis Modeling: Using mathematical models (e.g., Preisach model) that are calibrated for the specific textile material to predict the loading/unloading curves and correct the readings.

For a consumer product, this calibration and modeling need to be embedded in the product's firmware, often on a small microcontroller.

How is Pressure Data Mapped to a "Fit Score"?

The system must interpret pressure distribution maps to assess "good fit" vs. "poor fit." This involves:

- Zoning: Dividing the sensor map into relevant anatomical zones (e.g., nasal bridge, right cheek, left cheek, chin).

- Thresholds & Patterns: Defining ideal pressure ranges for each zone (e.g., the nasal bridge should have higher pressure than the cheeks) and identifying bad patterns (e.g., high pressure on the chin but zero pressure on one cheek indicates a lateral leak).

- Machine Learning: Training a classifier on data from many users with good and bad fits (verified by standard qualitative fit tests) to automatically recognize fit quality. This is the most robust approach but requires extensive data collection.

The output can be a simple traffic light indicator (green/yellow/red) on a paired app or a haptic vibration from the mask itself prompting a readjustment.

What Are the Key Application-Specific Requirements?

The optimal implementation of a piezoresistive fit-sensing textile varies dramatically depending on whether it's for a consumer mask, a medical respirator, or athletic wear.

What Standards Apply to Medical and Respiratory Protection?

For masks claiming to ensure fit for respiratory protection (e.g., elastomeric respirators), the sensing system itself may become part of the regulated device. Considerations include:

- Validation Against Quantitative Fit Testing (QNFT): The sensor output must correlate strongly with standard QNFT methods (e.g., PortaCount) used in occupational health.

- Environmental Robustness: The sensors must perform accurately across a range of temperatures and humidities and resist degradation from cleaning chemicals (alcohol wipes, disinfectants).

- Fail-Safe Design: If the sensor fails, it should default to indicating a "poor fit" to ensure safety.

Engaging with standards bodies like NIOSH or ISO (ISO 16975-3 for respirator fit) early in development is critical.

How are Consumer Products Simplified for Usability?

For the broad consumer market, complexity must be hidden:

- Minimal or No Calibration: The system should work "out of the box" for most users.

- Intuitive Feedback: Simple haptic (vibration), visual (LED), or auditory cues.

- Low Power: Must operate for a full day or week on a small battery, using aggressive sleep modes and waking only during donning or periodic checks.

The sensor textile here might have fewer sensing points (e.g., 4-6 key zones instead of a full grid) to reduce power and data processing needs.

Conclusion

The best piezoresistive fit-sensing smart textiles are those that seamlessly integrate high-sensitivity, durable conductive materials into comfortable fabric structures, supported by intelligent algorithms that convert noisy resistance data into reliable, actionable fit guidance. For mask applications, this technology promises to solve the perennial problem of subjective fit checking, potentially bringing quantitative fit assurance to the consumer market and enhancing safety in professional settings. While challenges in material stability, signal interpretation, and cost remain, ongoing advancements in nano-materials, flexible electronics, and edge computing are rapidly making robust, washable, and affordable fit-sensing textiles a commercial reality.

Ready to integrate intelligent fit-sensing capabilities into your next-generation mask or wearable product? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss development partnerships, material sourcing, and prototyping of piezoresistive smart textile solutions tailored to your specific application.