Volatile Organic Compounds (VOCs) in printed mask fabrics represent a significant health concern because these chemicals can off-gas and be inhaled directly during mask use. With increasing regulatory scrutiny and consumer awareness about chemical safety, comprehensive VOC testing has become essential for responsible mask manufacturing. Proper testing protocols ensure compliance with international standards while protecting end-users from potential respiratory irritation and long-term health effects.

The best practices for VOCs testing in printed mask fabrics include using GC-MS analysis following ISO 16000-6 standards, conducting both material and chamber testing, implementing supply chain transparency for ink formulations, and establishing strict acceptance criteria based on health-based thresholds. These practices identify hazardous compounds like formaldehyde, benzene, toluene, and phthalates that may originate from printing inks, dye fixatives, or fabric treatments.

The complexity of VOC testing stems from the diverse chemical formulations used in textile printing and the potential for compound transformation during manufacturing processes. Effective testing must account for both known hazardous substances and unexpected byproducts that may form during curing or storage. Let's examine the specific protocols that ensure comprehensive VOC assessment in printed mask fabrics.

What Testing Methodologies Provide Accurate VOC Assessment?

Multiple complementary testing approaches are necessary to fully characterize VOC emissions from printed mask fabrics.

How does gas chromatography-mass spectrometry (GC-MS) work for VOC testing?

GC-MS analysis following ISO 16000-6 separates and identifies individual VOCs from fabric samples through thermal extraction at temperatures simulating body heat and breathing conditions (typically 40-60°C). This method detects compounds at parts-per-billion levels, providing both qualitative identification and quantitative measurement. Our testing protocol includes scanning for 65+ target VOCs commonly found in textile printing while also screening for unexpected compounds through non-target analysis.

What is the role of emission chamber testing?

Environmental chamber testing according to ISO 12219-4 places fabric samples in controlled chambers that simulate real-world conditions, measuring VOC emissions over time. This approach better represents actual exposure scenarios than material-only analysis. Chamber testing has identified emission patterns that simple extraction misses, particularly for compounds that release gradually during wear rather than immediately upon unpackaging.

What Are the Critical Sampling and Preparation Protocols?

Proper sample handling and preparation are essential for obtaining accurate, representative VOC test results.

How should samples be selected and handled?

Representative sampling across production batches ensures testing reflects actual product rather than specially prepared samples. Samples should include fabrics from different print runs, color variations, and storage conditions. Strict chain of custody protocols prevent contamination during transport and storage. Our sampling strategy tests materials from the beginning, middle, and end of print runs, and includes accelerated aging to simulate storage conditions.

What conditioning procedures are necessary?

Pre-test conditioning in controlled environments (23°C ± 2°C, 50% ± 5% RH for 24 hours) standardizes sample conditions before testing. This eliminates variations caused by different storage or transportation environments. Additionally, samples should be tested at multiple time points after printing (24 hours, 7 days, 30 days) to understand emission profiles throughout the product lifecycle. Our data shows VOC emissions can decrease by 40-70% in the first week after printing, making timing critical for accurate assessment.

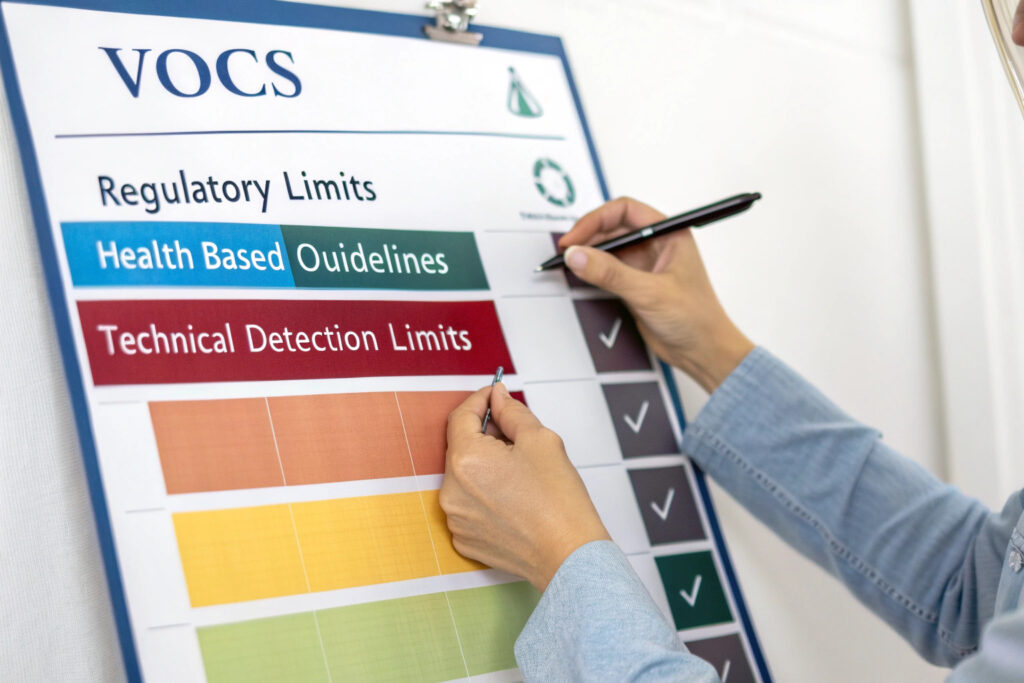

What Acceptance Criteria Should Be Established?

Setting appropriate pass/fail thresholds requires balancing regulatory requirements, health guidelines, and technical feasibility.

How are health-based thresholds determined?

Reference established exposure limits from organizations like WHO, EPA, and ECHA, then apply appropriate safety factors for sensitive populations and route-of-exposure considerations. For mask applications where inhalation is the primary exposure pathway, we recommend thresholds 5-10 times stricter than general product guidelines. Our criteria are based on the most protective guidelines from OEKO-TEX® STANDARD 100, BlueSign, and EU Ecolabel.

What about compound-specific considerations?

Individual compound assessment is essential because different VOCs present vastly different health risks. Formaldehyde and benzene require near-zero tolerance due to their carcinogenicity, while some alcohols and esters may be acceptable at higher concentrations. Our testing protocol includes compound-specific limits ranging from 10 μg/m³ for carcinogens to 500 μg/m³ for less concerning compounds.

How Can Supply Chain Management Reduce VOC Risks?

Prevention through supply chain control is more effective than detecting problems through finished product testing.

What ink manufacturer qualifications are important?

Comprehensive material disclosure from ink suppliers should include full chemical composition, VOC content percentages, and certification of compliance with relevant standards. Manufacturers should provide testing data from accredited laboratories for each ink batch. Our supplier qualification process requires ink manufacturers to meet ZDHC MRSL compliance and provide full disclosure of intentionally added substances down to 100 ppm.

How does production process control impact VOC levels?

Optimized curing processes significantly reduce residual VOCs by ensuring complete polymerization of inks and coatings. Temperature, time, and ventilation during curing must be carefully controlled and monitored. Our production monitoring has shown that proper curing can reduce detectable VOCs by 60-80% compared to suboptimal processes. Additionally, adequate ventilation during storage prevents VOC accumulation in packaged products.

What Documentation and Verification Systems Ensure Compliance?

Robust documentation creates accountability and enables continuous improvement in VOC management.

What should comprehensive test reports include?

Detailed analytical reports should identify all detected compounds above reporting limits, their concentrations, method detection limits, and comparison to established thresholds. The reports should also include quality control data demonstrating analytical validity. Our reporting format provides clear pass/fail determinations while also educating clients about detected compounds and their potential sources.

How can verification testing be structured?

Regular surveillance testing should occur quarterly or with each significant material change, supplemented by more frequent supplier self-testing with periodic verification. Unannounced audits of testing laboratories and manufacturing facilities ensure ongoing compliance. Our verification program includes blinded sample testing where identical samples are sent to multiple accredited laboratories to confirm result consistency.

What Are the Common VOC Sources in Printed Textiles?

Understanding where VOCs originate helps target prevention efforts most effectively.

Which printing processes typically have higher VOC concerns?

Plastisol and solvent-based printing historically contained high VOC levels, though modern formulations have improved significantly. Water-based printing generally has lower VOC content but may still contain coalescing agents and other additives that emit VOCs. Our analysis shows that even "eco-friendly" printing systems can emit concerning VOCs if not properly formulated and processed.

What about unexpected VOC sources?

Cross-contamination during manufacturing and secondary formation during storage can introduce VOCs not present in original formulations. For example, phthalates can migrate from plastic packaging, and formaldehyde can form through degradation of certain fixatives. Our root cause analysis has identified several such secondary sources that required changes in packaging and storage practices.

Conclusion

Implementing best practices for VOC testing in printed mask fabrics requires a comprehensive approach combining rigorous analytical methods, appropriate acceptance criteria, supply chain management, and thorough documentation. The most effective programs prevent problems through careful material selection and process control rather than relying solely on finished product testing. As regulatory requirements tighten and consumer awareness grows, robust VOC management becomes both a compliance necessity and competitive advantage.

The investment in proper VOC testing and control pays dividends through reduced liability, stronger brand reputation, and access to markets with stringent chemical regulations. More importantly, it demonstrates a commitment to consumer safety that aligns with the protective purpose of fabric masks themselves.

Ready to implement comprehensive VOC testing for your printed mask fabrics? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our testing protocols and how we can help ensure your products meet the highest standards for chemical safety. We'll provide specific guidance tailored to your printing methods and market requirements.