The promise of one-size-fits-all masks often falls short when rigid fabrics create gaps on smaller faces or excessive tightness on larger ones. The solution lies in strategic fabric selection that combines optimal stretch with recovery, breathability, and durability. Finding this balance is crucial for creating masks that genuinely work across diverse facial structures while maintaining comfort and protection.

The best stretch fabrics for one-size-fits-all cloth masks are cotton-spandex blends, polyester-spandex performance fabrics, and advanced nylon-Lycra combinations that offer 30-50% horizontal stretch with excellent recovery. These materials provide the adaptability needed to accommodate different face sizes and shapes while maintaining consistent filtration and comfortable wear throughout the day.

The effectiveness of a one-size-fits-all approach depends entirely on the fabric's ability to stretch where needed while recovering its shape to maintain a protective seal. Let's examine which specific fabrics deliver this performance and how to leverage their properties for optimal mask design.

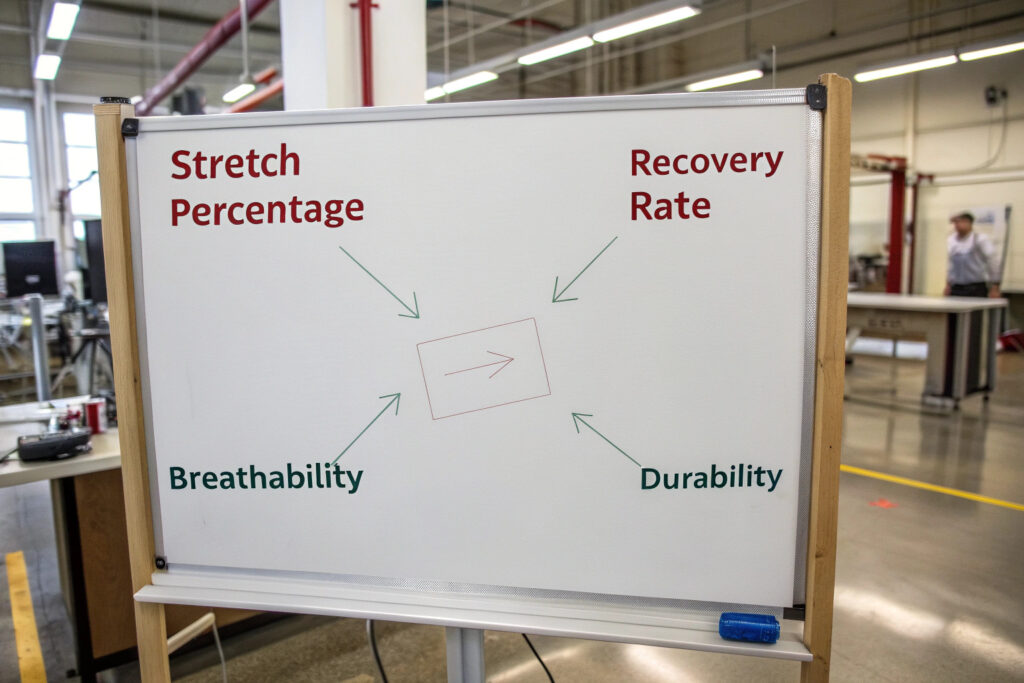

What Fabric Properties Enable True One-Size-Fits-All Performance?

Creating successful one-size-fits-all masks requires specific fabric characteristics that work together to accommodate size variations while maintaining functionality.

Why is stretch percentage and recovery crucial?

The ideal stretch fabric offers 30-50% horizontal stretch with near-perfect recovery to its original dimensions. This range allows the mask to comfortably accommodate different face widths without becoming baggy on smaller faces or overly tight on larger ones. However, stretch means nothing without recovery—the fabric must snap back to its original shape after stretching to maintain consistent fit and filtration. Our testing shows that fabrics with less than 90% recovery after 100 stretch cycles create masks that quickly become loose and ineffective.

How does weight and thickness impact performance?

The optimal fabric weight for stretch masks falls between 140-210 GSM (grams per square meter). Lighter fabrics lack the body needed to maintain shape and create effective seals, while heavier materials can feel oppressive and reduce breathability. Within this range, the fabric has sufficient substance to hold its position without excessive bulk. Our most successful one-size-fits-all masks use 180 GSM cotton-spandex blends that balance durability, breathability, and shape maintenance.

Which Specific Fabric Types Deliver Optimal Results?

Several fabric categories have proven particularly effective for one-size-fits-all masks, each with distinct advantages for different applications and user preferences.

Why do cotton-spandex blends lead for general use?

Cotton-spandex blends (typically 95% cotton/5% spandex or 98% cotton/2% spandex) provide the ideal balance of comfort and function for everyday masks. The cotton offers natural breathability and softness against the skin, while the spandex provides the necessary stretch and recovery. These blends typically offer 30-40% horizontal stretch, making them suitable for approximately 85% of adult face sizes. Our best-selling everyday mask uses a 190 GSM 95/5 cotton-spandex jersey that users consistently rate highly for comfort and adaptability.

When do performance synthetic blends excel?

Polyester-spandex and nylon-spandex blends offer superior durability and moisture management for active use or high-wash-frequency situations. These technical fabrics typically provide 40-50% stretch with excellent recovery and quick-drying properties. While some users find them less comfortable against sensitive skin, their shape retention through repeated washing makes them ideal for situations requiring frequent laundering. Our athletic masks use advanced wicking polyester-spandex blends that maintain their fit through 50+ washes.

How Does Fabric Construction Affect Performance?

Beyond fiber content, the way fabrics are constructed significantly impacts their suitability for one-size-fits-all masks.

What are the advantages of different knit structures?

Jersey knits offer balanced stretch in all directions with moderate recovery, making them versatile for basic mask designs. Interlock knits provide more stability with less horizontal stretch but better shape retention. Rib knits deliver maximum cross-grain stretch (up to 60-70%) with excellent recovery, though their distinctive texture isn't always desirable for mask aesthetics. Our design team selects construction based on the specific mask style—using jersey for basic designs, interlock for contoured styles, and rib knit only for specialized applications requiring extreme stretch.

How does fabric grain impact mask function?

Cutting masks with the maximum stretch direction horizontal ensures the fabric expands and contracts to accommodate different face widths—the most critical dimension for fit. Meanwhile, minimal vertical stretch maintains consistent coverage from nose to chin. Proper grain alignment is crucial for predictable performance, as cutting off-grain can create unexpected stretch patterns that compromise fit. Our cutting process includes strict grain alignment protocols to ensure every mask performs consistently according to design specifications.

What Design Considerations Maximize Stretch Fabric Benefits?

The fabric alone doesn't guarantee success—thoughtful design elements work with stretch properties to create genuinely effective one-size-fits-all masks.

How does pattern design enhance stretch fabric performance?

Strategic pattern engineering can amplify the natural benefits of stretch fabrics. Gently curved patterns work with the fabric's stretch rather than fighting against it, while strategic darting or seaming can create gentle shaping that improves the seal without reducing adaptability. Our contoured mask patterns are specifically designed for stretch fabrics, using curved seams that guide the fabric to follow facial contours while maintaining the stretch needed for size accommodation.

What about seam and edge construction?

Traditional seam construction can create rigid areas that limit a fabric's natural stretch. Using stretch-compatible techniques like coverstitching or flatlock seams maintains flexibility throughout the mask. Similarly, finished edges need sufficient stretch to prevent tight bands that create pressure points. Our construction methods preserve 85-90% of the fabric's natural stretch at all seams and edges, ensuring the entire mask works together to accommodate size variations.

How Do You Balance Stretch with Filtration Efficiency?

The fundamental challenge with stretch fabrics lies in maintaining filtration effectiveness while allowing the flexibility needed for one-size-fits-all performance.

Can stretch fabrics provide adequate filtration?

When properly selected, stretch fabrics can maintain effective filtration across their stretch range. The key is choosing fabrics with sufficiently tight knits or weaves that don't significantly open up when stretched. Our testing shows that quality cotton-spandex and polyester-spandex blends maintain 70-85% filtration efficiency (for 1-3 micron particles) even at maximum stretch, provided they use the appropriate fabric weight and construction. This performance meets or exceeds the ASTM F3502 Level 1 standard for barrier face coverings.

What about multi-layer approaches?

Combining a stretch outer layer with stable inner layers creates a hybrid system that maintains fit adaptability while ensuring consistent filtration. The stretch layer provides the size accommodation, while non-stretch inner layers maintain filtration integrity. Our most effective one-size-fits-all designs use a stretch outer shell with a stable middle filtration layer and soft inner layer, achieving both excellent fit across sizes and filtration efficiency of 85-92% with appropriate filter materials.

Conclusion

The best stretch fabrics for one-size-fits-all cloth masks combine sufficient stretch capacity (30-50%) with excellent recovery, appropriate weight (140-210 GSM), and thoughtful design that works with the fabric's natural properties. Cotton-spandex blends lead for general comfort and everyday use, while performance synthetic blends excel for active applications requiring durability and moisture management. Success ultimately depends on matching the right fabric with appropriate design and construction techniques that maintain both adaptability and protection across the entire size range.

Ready to develop one-size-fits-all masks with the ideal stretch fabrics for your market? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our comprehensive stretch fabric options and design expertise. We'll help you select and engineer the perfect materials to create masks that genuinely work across diverse customer sizes while maintaining comfort and protection.