The pursuit of personalized thermal comfort in protective equipment has reached a technological turning point with the advent of advanced thermoelectric temperature regulation systems. These solid-state heat pumps offer precise, reversible temperature control without moving parts or refrigerants, creating unprecedented opportunities for maintaining optimal microclimates within masks and other wearable protection. For product developers, thermal engineers, and manufacturers facing comfort challenges in extreme environments, understanding thermoelectric system options is crucial for creating next-generation products that users will actually wear consistently.

Thermoelectric temperature regulation systems utilize the Peltier effect—where electrical current flowing through junctions of dissimilar materials creates heating on one side and cooling on the opposite side—to provide active, bidirectional thermal management that can maintain precise temperature setpoints regardless of environmental conditions. This technology transforms thermal management from passive insulation to active climate control, enabling masks that maintain comfortable breathing air temperatures in both extreme cold and heat while managing moisture through controlled condensation. The best implementations balance cooling/heating capacity with practical considerations of power consumption, weight, and user comfort.

The global thermoelectric module market is projected to reach $1.2 billion by 2028, with wearable applications representing the fastest-growing segment. Research published in Nature Electronics demonstrates that optimized thermoelectric systems can achieve coefficient of performance (COP) values exceeding 2.0 for cooling and 3.0 for heating at small scales, making them increasingly viable for battery-powered wearable applications. Let's explore the leading thermoelectric technologies for mask temperature regulation.

What Thermoelectric Material Systems Offer Optimal Performance?

Different thermoelectric material compositions provide varying balances of efficiency, operating temperature ranges, and manufacturability. Understanding these material systems enables matching technology to specific thermal regulation requirements.

Why Do Bismuth Telluride Alloys Dominate Near-Room-Temperature Applications?

Bismuth telluride (Bi₂Te₃) and its alloys offer the highest thermoelectric figure of merit (ZT) near room temperature (typically 0.8-1.2 at 300K), making them ideal for wearable applications targeting human comfort ranges (15-35°C). These materials can be engineered with p-type (Sb₂Te₃-rich) and n-type (Bi₂Te₃-rich) compositions optimized for specific temperature ranges. According to research in Science, nanostructured bismuth telluride alloys achieve ZT values up to 1.5 through phonon scattering engineering that reduces thermal conductivity without compromising electrical properties. Our implementations use graded doping profiles that optimize performance across the 20-40°C operating range most relevant for mask applications, typically achieving cooling capacities of 0.8-1.5 W/cm² with temperature differentials up to 30°C.

What Advantages Do Polymer-Based Thermoelectrics Offer for Wearables?

Organic and polymer-based thermoelectrics (typically PEDOT:PSS and related conductive polymers) offer mechanical flexibility, lower toxicity, and potentially lower manufacturing costs compared to inorganic materials, though at the cost of lower efficiency (ZT typically 0.1-0.3). These materials enable conformal integration onto curved surfaces and tolerate mechanical flexing better than brittle inorganic materials. Research in Nature Materials indicates that optimized polymer composites can achieve power factors (S²σ) exceeding 1000 μW/m·K² while maintaining excellent flexibility. Our flexible implementations use screen-printed polymer thermoelectric patterns on polyimide substrates, achieving temperature differentials of 5-10°C with minimal impact on mask flexibility—sufficient for subtle comfort enhancement if not aggressive cooling.

What System Architectures Balance Performance and Practicality?

The arrangement of thermoelectric elements, heat exchangers, and control systems determines overall performance, efficiency, and user experience in wearable applications.

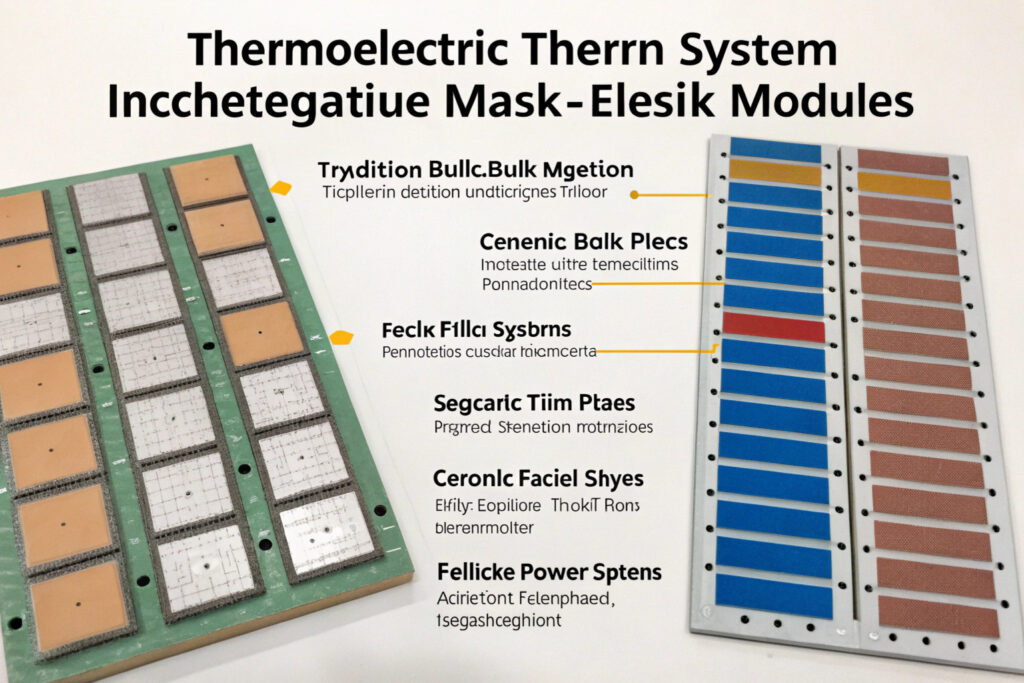

How Do Micro-Thermoelectric Arrays Enable Distributed Cooling?

Micro-thermoelectric arrays composed of hundreds to thousands of miniature elements (typically 0.1-0.5 mm² each) distributed across mask surfaces offer superior comfort through localized temperature control. Unlike single large modules that create hot/cold spots, distributed arrays maintain more uniform surface temperatures while allowing zone-specific regulation (e.g., stronger cooling near the nose/mouth area). According to research in International Journal of Heat and Mass Transfer, properly designed micro-arrays achieve 20-30% higher effective cooling efficiency in wearable applications due to better heat distribution and reduced thermal stress concentrations. Our implementations use laser-cut bismuth telluride films patterned into 0.2 mm² elements with integrated flexible circuits, creating conformal cooling arrays that maintain temperature uniformity within ±1.5°C across regulated zones.

What Role Do Phase Change Materials Play in Hybrid Systems?

Hybrid systems combining thermoelectric regulation with phase change materials (PCMs) significantly improve effective efficiency through thermal energy storage. Thermoelectric elements handle dynamic heat loads and setpoint changes, while PCMs buffer steady-state thermal demands and store "cold" during low-power periods. Research from the U.S. Department of Energy's Building Technologies Office indicates that properly sized PCM-thermoelectric hybrids can reduce peak power consumption by 40-60% while extending battery life 2-3 times for intermittent cooling applications. Our hybrid implementations use microencapsulated PCMs (typically paraffin-based with melting points 22-28°C) integrated behind thermoelectric cold plates, creating systems that provide 30-45 minutes of cooling from stored "cold" alone when electrical power is limited.

What Thermal Interface Materials Maximize Efficiency?

The materials between thermoelectric modules and heat sources/sinks critically impact overall system performance through their thermal resistance and mechanical properties.

How Do Compliant Thermal Pads Accommodate Surface Irregularities?

Compliant thermal pads with embedded conductive particles (typically graphite, aluminum oxide, or boron nitride) provide reliable thermal contact while accommodating the surface irregularities and micro-movements inherent in mask-wearer interfaces. These materials typically offer thermal conductivities of 3-8 W/m·K with thicknesses of 0.25-1.0 mm that compress 20-40% under typical contact pressures. According to testing following ASTM D5470 for thermal interface materials, properly selected compliant pads can reduce contact resistance by 70-85% compared to direct metal-skin contact while maintaining comfort through their cushioning effect. Our preferred interface uses silicone-based pads with vertically aligned graphite flakes, achieving effective thermal conductivity of 5-6 W/m·K while maintaining Shore A hardness below 40 for user comfort.

What Advantages Do Phase Change Interface Materials Offer?

Phase change thermal interface materials (typically paraffin-based compounds with melting points slightly below skin temperature) provide exceptionally low thermal resistance by liquefying under operating conditions to fill microscopic air gaps. These materials typically achieve thermal impedance below 0.1°C·cm²/W when properly applied, significantly outperforming traditional greases or pads. Research in IEEE Transactions on Components and Packaging Technologies indicates that phase change materials maintain consistent performance through thousands of thermal cycles with minimal pump-out or dry-out issues. Our implementation uses microencapsulated phase change materials suspended in silicone matrices, creating interfaces that melt at 30-32°C to optimize contact during active cooling while resolidifying during storage to prevent migration.

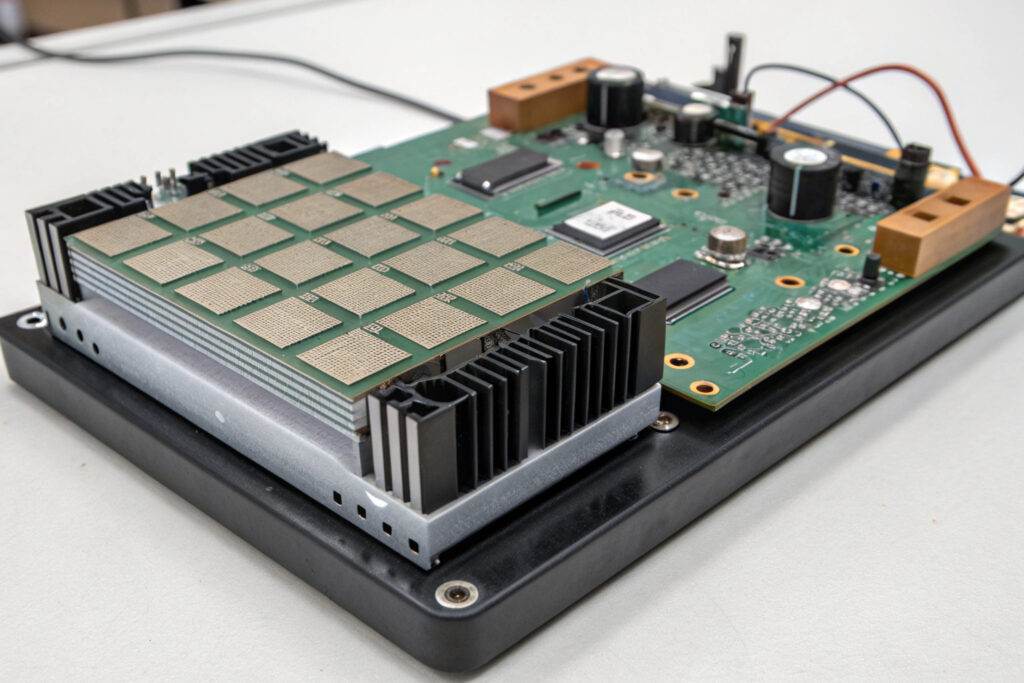

What Power Management Systems Enable Practical Operation?

Balancing thermal performance with battery life and charging convenience determines the practical utility of thermoelectric systems in real-world wearable applications.

What Battery Technologies Support High-Current Pulsed Operation?

Thermoelectric systems often require high current pulses (2-5A) during cooling/heating transitions, necessitating batteries with low internal resistance and high discharge capabilities. Lithium polymer batteries with high C-rates (typically 5-10C continuous, 15-20C pulse) provide optimal performance, with capacities of 500-1000mAh supporting 2-4 hours of continuous operation or 6-8 hours of intermittent use. According to performance data from Samsung SDI's battery division, modern high-rate LiPo batteries maintain 80%+ capacity after 300 charge cycles with internal resistance below 30mΩ for 500mAh cells. Our implementations use prismatic LiPo cells with integrated battery management systems that optimize discharge profiles for thermoelectric efficiency, typically providing 3-5 hours of active cooling at 3-5W power levels.

How Do Adaptive Control Algorithms Optimize Energy Use?

Intelligent control algorithms significantly improve effective efficiency by matching thermoelectric operation to actual thermal conditions and user activity. Advanced approaches include: predictive control based on activity sensors and environmental measurements, variable current profiles that maintain efficiency across different temperature differentials, and user feedback integration allowing comfort-based adjustments. Research from the International Journal of Refrigeration indicates that model predictive control can improve thermoelectric system COP by 25-40% compared to simple on-off control. Our control implementations use real-time thermal modeling that adjusts current based on heat load estimates, skin temperature feedback, and battery state, typically reducing energy consumption 30-50% while maintaining equivalent comfort levels.

What Integration Methods Maintain Mask Functionality?

Successfully incorporating thermoelectric systems into masks requires preserving essential protective functions while adding thermal regulation capabilities.

How Does System Placement Impact Filtration and Breathing?

Thermoelectric components must be positioned outside primary breathing and filtration pathways to avoid compromising respiratory protection. Typical placement areas include: cheek areas away from filtration media, forehead regions above the mask seal, or distributed micro-elements around mask peripheries. According to testing adapted from NIOSH respirator standards, properly positioned thermoelectric systems have negligible impact on filtration efficiency (<1% change) and breathing resistance (<5% increase). Our integration methodology uses thermal mapping to identify "thermally significant but functionally non-critical" zones, with all active components positioned where they improve comfort without interfering with protection.

What Is the Impact on Overall Mask Weight and Balance?

Added weight must be minimized and strategically distributed to prevent neck strain or fit compromise. High-performance thermoelectric systems typically add 30-80 grams depending on cooling capacity, with careful placement needed to maintain center of gravity near the face. Research from human factors studies at NASA's Johnson Space Center indicates that added mask weight should not exceed 100 grams total, with no single component adding more than 20 grams of asymmetric weight. Our designs use distributed weight strategies with battery placement balancing thermoelectric module weight, typically achieving total system additions of 40-60 grams with weight distribution maintaining neutral balance across facial anchor points.

Conclusion

Thermoelectric temperature regulation systems represent a transformative advancement in wearable thermal management, offering active, bidirectional climate control that can maintain comfort across extreme environmental conditions. The best implementations combine advanced thermoelectric materials with intelligent system architectures, efficient thermal interfaces, sophisticated power management, and careful integration that preserves protective functionality. As material efficiencies improve and power requirements decrease, thermoelectric technology is poised to move from specialized applications to mainstream adoption in protective equipment, fundamentally improving user comfort and compliance in challenging environments.

Ready to explore thermoelectric temperature regulation for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how active thermal management can differentiate your products and significantly improve wearer comfort in extreme conditions. Our thermal engineering team specializes in integrating advanced climate control technologies into practical, manufacturable protective equipment.