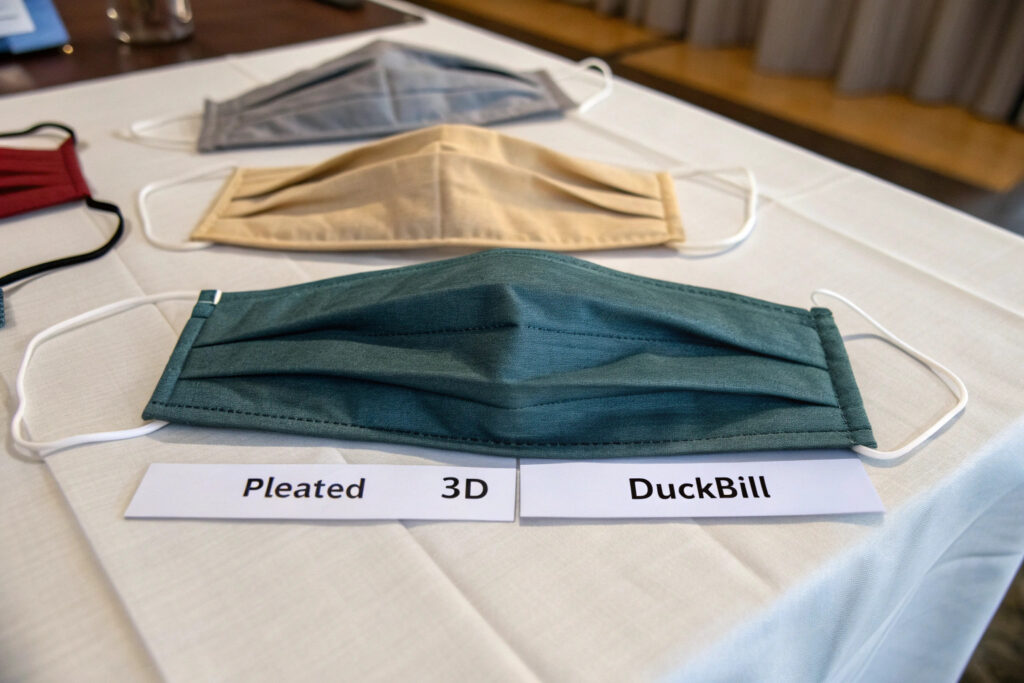

In today’s highly competitive global mask market, understanding the true cost implications of different construction styles is critical for making smart purchasing and manufacturing decisions. As a manufacturer with over 10 years of experience producing fabric masks for international clients, I have seen how subtle differences in design—such as pleated, 3D, and duckbill styles—can significantly affect not only production costs but also logistics, customization, and retail positioning.

The short answer? Pleated masks tend to be the most budget-friendly, 3D masks sit in the mid-range, and duckbill masks are often the most expensive to produce. But there’s more to the story than just unit price.

If you are sourcing for bulk orders or retail distribution, the decision should balance your target market, functional requirements, and total landed cost. Let’s break down the pros, cons, and cost factors of each mask construction type.

Pleated Masks: Balancing Cost and Versatility

Pleated masks remain a staple in the fabric mask industry because they are cost-efficient, easy to produce, and adaptable to many markets.

Pleated masks use rectangular panels with horizontal folds, allowing them to expand over the nose and mouth. The simple structure makes them ideal for rapid production and efficient shipping.

Why are pleated masks often cheaper to produce?

The cost advantage comes from their straightforward manufacturing process. Cutting flat panels produces minimal fabric waste, and sewing straight seams is faster compared to curved designs. According to CDC mask guidance, the pleated style also works well for adding layers or filters without much extra labor.

Shipping is another factor—pleated masks pack flat, which means you can fit more units into each carton. This lowers per-unit freight costs, which is especially important for buyers managing tight margins. We have shipped containers of over 200,000 pleated masks to U.S. distributors, optimizing both price and delivery efficiency.

How do pleated mask customization options affect pricing?

Custom prints, antimicrobial coatings, or adjustable features can raise the unit cost by 5–10%. Flat panels are well-suited to digital printing, as explained in Textile World, making branding cost-effective. However, buyers should budget for extra time and cost if adding metal nose bridges, ear adjusters, or multi-layer constructions.

3D Masks: Comfort Comes at a Price

3D masks, also called contour or molded masks, provide a snug fit and stylish look, but they cost more to make.

Their construction involves multiple curved fabric pieces sewn together, which takes more time and precision.

Why do 3D masks require more labor and materials?

Compared to pleated masks, 3D designs require precision cutting of curved panels, which creates more fabric waste. As Sew Guide’s mask pattern analysis notes, stitching along curves is slower and requires skilled labor. In our production lines, we see a 20–25% longer sewing time, which directly increases labor costs.

Materials are also a factor. 3D masks often use sturdier fabrics or internal linings to keep their shape. Adding nose bridges or filter pockets can push the cost up further.

Are 3D masks worth the higher production cost?

For many brands, yes. Retailers report fewer fit issues and higher customer satisfaction with 3D masks. Fashion brands in Europe and North America often choose this style for premium collections. The better fit and perceived quality help justify a higher price point. According to Business of Fashion, investing in better design can increase brand loyalty and repeat sales.

Duckbill Masks: Niche Design with Specialized Costs

Duckbill masks stand out for their unique pointed profile, offering extra breathing space. They are common in medical or industrial settings but have specialized cost drivers.

What makes duckbill masks more expensive to manufacture?

Duckbill masks require additional shaping steps, sometimes involving heat molding or reinforced seams. The pattern produces more fabric waste, and specialized dies add tooling costs. NIOSH respirator guidelines highlight the structural benefits of this style, but those benefits come with a higher price tag.

When do duckbill masks make financial sense for buyers?

They are ideal for environments where comfort and breathability are critical. Industrial and healthcare buyers may see productivity gains from reduced wearer fatigue. In fashion markets, duckbill designs remain niche, but some avant-garde brands use them for statement pieces. As Vogue Business points out, unique designs can command premium pricing in targeted segments.

Comparing the Cost Impact Across Styles

When choosing a mask style, cost analysis should consider more than production alone.

How do logistics and packaging affect final costs?

Pleated masks ship flat, making them cheapest to transport. 3D masks require more volume per unit, while duckbill masks take the most space. Freightos freight pricing guides show how shipping volume can significantly impact landed cost. Packaging—such as branded boxes or retail-ready polybags—will also influence freight rates.

Which style offers the best balance for different markets?

For discount retail and large-scale distribution, pleated masks usually win on cost efficiency. For fashion and lifestyle brands, 3D masks balance cost and customer appeal. For industrial or medical buyers, duckbill masks justify their higher cost through performance benefits.

Conclusion

The choice between pleated, 3D, and duckbill mask styles depends on your target market, brand positioning, and total landed cost. Pleated masks keep budgets low, 3D masks offer style and comfort, and duckbill masks serve specialized performance needs.

If you are ready to develop your own custom mask collection, contact our Business Director Elaine at elaine@fumaoclothing.com to discuss your project and production needs with Shanghai Fumao.