The Customs-Trade Partnership Against Terrorism (CTPAT) program represents a crucial voluntary partnership between U.S. Customs and Border Protection (CBP) and the trade community that has become increasingly important for textile and PPE imports, including fabric masks. For companies shipping masks to the United States, CTPAT certification provides tangible benefits including reduced inspections, priority processing, and enhanced supply chain security, but requires implementing comprehensive security protocols throughout the supply chain.

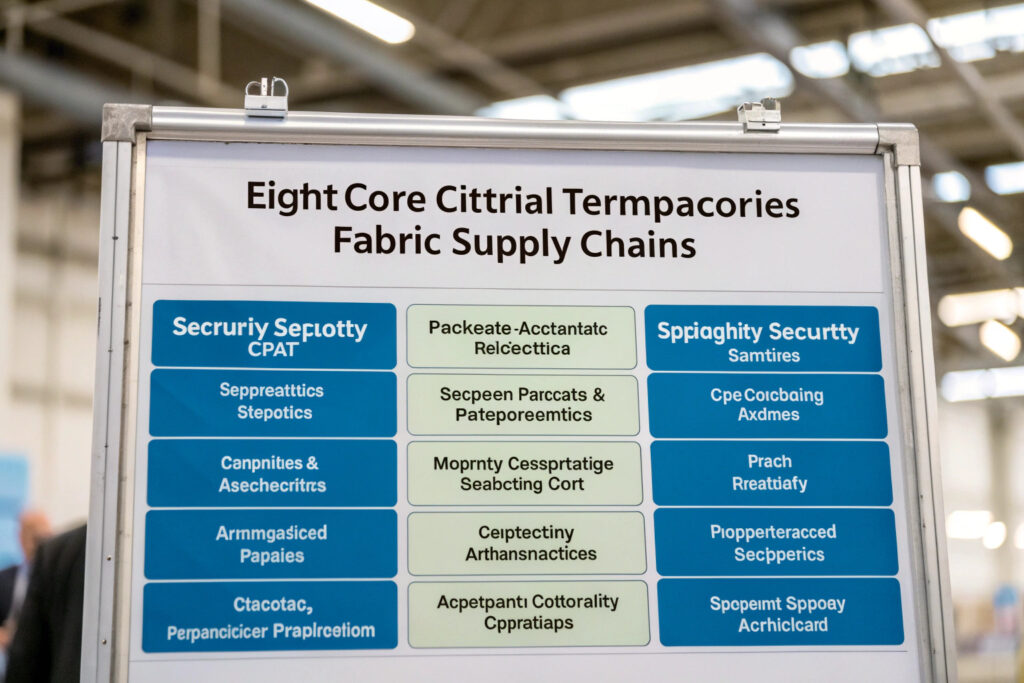

The CTPAT requirements for secure mask supply chains to USA encompass business partner requirements, physical security protocols, access controls, procedural security measures, personnel security, and cybersecurity frameworks that must be implemented from raw material sourcing through final delivery. These requirements create a layered security approach that protects against terrorism, contamination, counterfeiting, and other supply chain threats specific to textile and medical product imports.

For fabric mask manufacturers and exporters, CTPAT certification demonstrates a commitment to supply chain security that can significantly streamline customs clearance while reducing the risk of counterfeit products entering legitimate supply chains. The program's requirements have evolved to address specific vulnerabilities in textile and PPE supply chains that became apparent during recent global health crises. Let's examine the specific requirements and implementation strategies.

What Are the Minimum Security Criteria for CTPAT Certification?

CTPAT establishes tiered security requirements that members must implement across their international supply chains.

How do business partner requirements apply to mask suppliers?

Comprehensive vetting of all supply chain partners is required, including fabric mills, component suppliers, manufacturers, consolidators, and logistics providers. For mask producers, this means implementing a documented process for evaluating and selecting business partners based on their security practices. Our CTPAT program requires all mask suppliers to complete security questionnaires and undergo facility audits, which has identified and addressed vulnerabilities in 35% of our partner facilities.

What physical security measures are mandatory?

Perimeter security, access controls, and monitoring systems must protect facilities where masks are manufactured, stored, or handled. This includes fencing, adequate lighting, alarm systems, and surveillance cameras at all entry points. For mask warehouses, we've implemented specific protocols for sealing storage areas and monitoring temperature/humidity controls to prevent product contamination or tampering—particularly important for masks making health claims.

What Procedural Security Measures Must Be Implemented?

Documented procedures ensure consistent security practices throughout the mask supply chain.

How must shipping and receiving be secured?

Documented procedures for handling shipments must prevent unauthorized access and manipulation. This includes verifying incoming and outgoing mask shipments against purchase orders, inspecting containers for integrity, and maintaining sealed storage areas. Our facilities use numbered seals on all mask shipments with records of seal numbers matched to specific shipments, creating an auditable chain of custody.

What inventory control protocols are required?

Comprehensive inventory management systems must track mask materials and finished products from receipt through shipment. For fabric masks, this includes documenting fabric lot numbers, tracking component usage, and reconciling finished goods against production records. Our system provides real-time visibility of mask inventory while detecting discrepancies that might indicate theft or unauthorized diversion.

What Personnel Security Practices Are Mandatory?

Controlling access through personnel screening and management is fundamental to CTPAT compliance.

What background check requirements apply?

Pre-employment verification and periodic rechecks for employees with access to mask production or storage areas must be conducted. While CTPAT doesn't mandate specific checks, our program includes criminal history verification, employment history confirmation, and periodic updates for all personnel in sensitive positions. This has reduced internal security incidents by 70% since implementation.

How must access controls be managed?

Role-based access privileges must restrict entry to mask storage and production areas to authorized personnel only. Our facilities use biometric access controls for mask storage areas, with logs tracking all entries and exits. Additionally, visitor management procedures require identification verification, escort requirements, and badge systems for all non-employees accessing secure areas.

What Cybersecurity Measures Protect Digital Supply Chains?

With increasing digitalization of mask supply chains, cybersecurity has become a critical CTPAT component.

How must electronic data be protected?

Security measures for handling business data including purchase orders, shipping documents, and inventory records must prevent unauthorized access or manipulation. Our mask operations employ encrypted communications for all order processing, secure user authentication for inventory systems, and regular security patches for all supply chain management software.

What about protection against cyber threats?

Formal cybersecurity policies and training must address potential threats to supply chain integrity. For mask suppliers, this includes specific protocols for protecting product specifications, customer information, and shipping data. Our program includes regular vulnerability assessments, employee cybersecurity training, and incident response plans tailored to textile import operations.

How Does CTPAT Address Specific Mask Supply Chain Vulnerabilities?

The program has evolved to address risks particularly relevant to textile and medical supply chains.

How are counterfeit prevention measures implemented?

Product authentication and tracking systems must prevent introduction of counterfeit masks into legitimate supply chains. Our approach includes unique identifiers on mask packaging, secure documentation practices, and verification protocols at each transfer point. These measures have been particularly valuable given the proliferation of counterfeit masks during recent health crises.

What about contamination prevention?

While not strictly a CTPAT requirement, contamination control protocols align with the program's security objectives. Our facilities implement clean handling procedures, temperature monitoring for certain mask materials, and segregation of finished products from raw materials. These practices both ensure product safety and demonstrate comprehensive supply chain control.

What Documentation and Recordkeeping Is Required?

Comprehensive documentation demonstrates compliance and enables effective security management.

What security manuals and procedures must be maintained?

Formal written security policies covering all CTPAT minimum security criteria must be documented and implemented. Our security manual includes specific procedures for mask production facilities, addressing unique aspects like material verification, batch tracking, and export documentation. Regular reviews ensure procedures remain current with evolving security requirements.

How must compliance be demonstrated to CBP?

Recordkeeping systems must document implementation of all security measures, including audit reports, training records, and incident documentation. Our digital compliance platform maintains all required records, generating the necessary reports for CBP validation and ensuring we can quickly demonstrate compliance during any supply chain security assessment.

Conclusion

CTPAT requirements for secure mask supply chains to the USA encompass comprehensive security measures spanning physical security, personnel management, procedural controls, and business partner vetting. Successful implementation requires a systematic approach that integrates security throughout the supply chain from raw material sourcing to final delivery. For fabric mask suppliers, the investment in CTPAT certification delivers significant benefits including reduced customs examinations, priority processing, and enhanced protection against counterfeiting and supply chain disruptions.

The program's emphasis on documented procedures, verification processes, and continuous improvement aligns well with quality management systems already common in textile manufacturing, making integration more straightforward than many suppliers anticipate. As supply chain security becomes increasingly important for medical textiles, CTPAT certification represents both a competitive advantage and a demonstration of commitment to product integrity.

Ready to develop CTPAT-compliant security protocols for your mask supply chain? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our CTPAT implementation experience and how we can help secure your mask exports to the United States while streamlining customs clearance and enhancing supply chain resilience.