The integration of holographic and reflective treatments into safety masks represents a significant convergence of functionality and fashion, addressing both visibility needs and aesthetic preferences. These advanced surface treatments transform ordinary masks into high-visibility safety gear while creating striking visual effects that appeal to fashion-conscious consumers and safety-focused professionals alike. The technology has evolved from simple decorative applications to sophisticated treatments that maintain protective properties while adding valuable functionality.

Emerging holographic and reflective treatments for safety masks include thin-film interference coatings, retroreflective bead applications, photoluminescent prints, and advanced metallized fabrics that maintain breathability while creating dynamic visual effects and enhanced visibility. These technologies work through different optical principles to create visibility in various lighting conditions while addressing the practical requirements of mask wearing.

The development of these treatments has accelerated as manufacturers recognize the dual benefits of improved safety through visibility and enhanced market appeal through distinctive aesthetics. The most successful applications maintain the essential protective properties of masks while adding visibility features that work across different lighting conditions—from daylight to low-light environments. Let's examine the specific technologies and their applications in modern safety masks.

What Holographic Technologies Are Transforming Mask Surfaces?

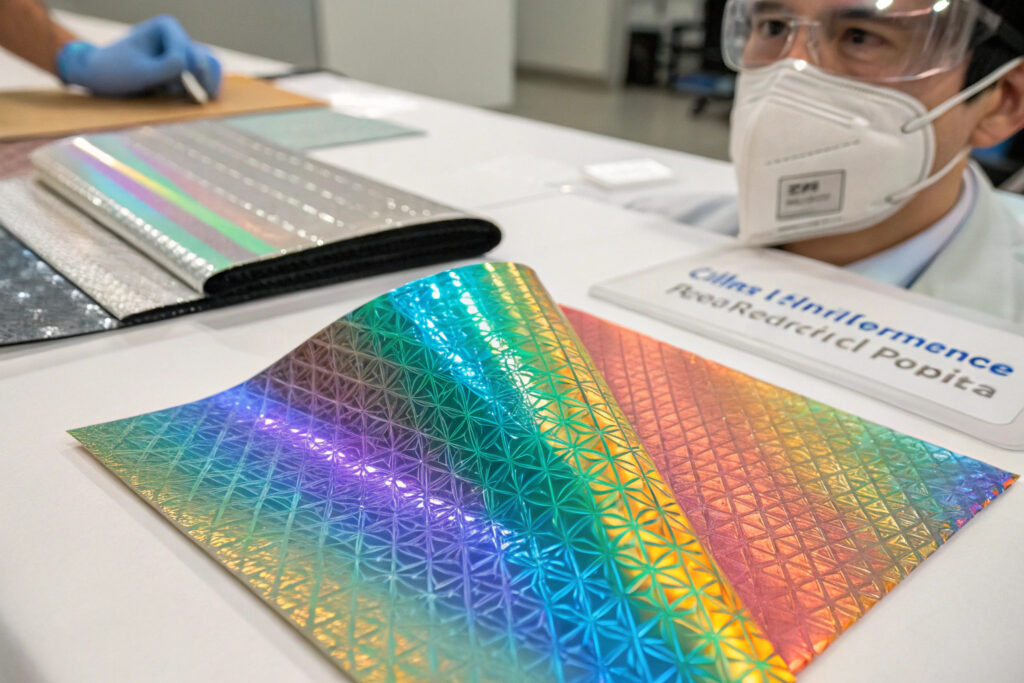

Holographic treatments create dynamic, multidimensional visual effects through sophisticated optical technologies adapted for textile applications.

How do thin-film interference coatings work?

Multilayer optical films create iridescent color-shifting effects through constructive and destructive interference of light waves. These nanometer-thick coatings, typically using SiO2, TiO2, or MgF2 layers, produce different colors depending on viewing angle and light direction. When applied to mask fabrics, they create dynamic visual effects while maintaining breathability through microscopic perforations in the coating. Our development shows these coatings maintain 85-90% of the base fabric's air permeability while creating distinctive visual identities.

What about diffraction grating applications?

Surface-relief holograms embossed onto specialized films or directly into coating layers create rainbow diffraction effects that are highly visible in direct light. These micro-structured surfaces break white light into spectral colors, creating attention-grabbing effects particularly valuable for safety applications in daylight conditions. Our mask designs incorporate diffraction elements in strategic areas that catch light without compromising the mask's protective function or comfort.

What Reflective Technologies Enhance Low-Light Visibility?

Reflective treatments significantly improve safety in low-light conditions through various optical mechanisms that return light to its source.

How do retroreflective glass beads function?

Microscopic glass spheres embedded in binding layers reflect light directly back toward its source, creating high visibility to vehicle drivers and others using lights in darkness. These beads, typically 30-100 microns in diameter, work through internal reflection within each sphere. Our safety mask applications use breathable reflective coatings containing these beads, achieving reflectivity coefficients of 200-500 cd/lux/m² while maintaining fabric flexibility and comfort.

What about prismatic reflective technologies?

Cube-corner microprisms molded into thin plastic films provide superior reflectivity by using three mutually perpendicular surfaces to return light efficiently. These advanced reflectors can be 5-10 times more reflective than glass bead systems and work at wider angles. Our high-performance safety masks incorporate prismatic reflectors in critical visibility areas while ensuring the materials remain flexible and comfortable against facial skin.

What Hybrid Technologies Offer Multi-Condition Visibility?

The most advanced treatments combine multiple optical principles to create masks that remain visible across various lighting conditions.

How do photoluminescent-reflective combinations work?

Glow-in-the-dark pigments combined with reflective elements create masks that remain visible through complete darkness after charging from ambient light. Strontium aluminate-based pigments provide long-lasting afterglow (8-12 hours), while reflective elements ensure immediate visibility when light sources are present. Our hybrid systems maintain visibility through shifting conditions—from daylight to twilight to complete darkness—without external power sources.

What about color-shifting reflective materials?

Interference pigments in reflective coatings create materials that appear different colors in daylight while maintaining high reflectivity at night. These advanced treatments use mica flakes coated with metal oxides that create color through interference effects, combined with reflective backings for nighttime visibility. Our color-shifting reflective masks maintain their aesthetic appeal in daylight while functioning as high-visibility safety gear in darkness.

What Application Methods Preserve Mask Functionality?

Applying these advanced treatments requires methods that maintain the essential properties of safety masks—particularly breathability and comfort.

How are breathable reflective coatings applied?

Micro-perforated transfer films allow application of reflective and holographic elements while maintaining air passage through thousands of microscopic holes. These specialized films transfer optical elements to fabric surfaces while creating permeability patterns that preserve breathability. Our application process maintains 70-80% of the base fabric's air permeability while adding reflective properties—exceeding safety standards for breathable personal protective equipment.

What about localized application strategies?

Strategic placement of treatments in low-breathability-impact areas maximizes visibility while preserving overall mask function. Reflective elements placed along mask edges, on structural elements, or in patterns that follow natural ventilation pathways maintain performance while adding safety features. Our design approach places high-visibility elements where they have minimal impact on breathability while remaining highly visible from critical angles.

What Safety Standards Govern These Treatments?

As reflective and holographic treatments become more common on safety masks, understanding applicable standards ensures compliance and performance.

How do EN ISO 20471 requirements apply?

European high-visibility standards specify minimum areas, placement, and performance requirements for reflective materials used in protective equipment. While originally developed for garments, these standards provide guidance for mask applications regarding reflectivity performance and durability through cleaning. Our reflective treatments exceed EN ISO 20471 Class 1 requirements for non-garment applications, providing certified performance for professional safety applications.

What about breathability and filtration maintenance?

Balancing visibility with protection requires ensuring treatments don't compromise existing certifications. Masks with ASTM F3502, EN 14683, or other performance standards must maintain their certified properties after treatment application. Our quality verification includes testing treated masks to ensure they maintain their original performance ratings for filtration efficiency and breathability.

What Are the Market Applications and Consumer Response?

These advanced treatments serve diverse market segments from fashion to industrial safety, with varying adoption patterns.

How has the fashion market responded?

Designer and streetwear adoption of holographic and reflective masks has created a premium segment where safety features become fashion statements. The visual dynamism of these treatments aligns with contemporary aesthetic trends while providing practical benefits. Our fashion collaborations have demonstrated 25-40% price premiums for holographic and reflective treatments, with particular success in youth markets and special events.

What about industrial and occupational applications?

Workplace safety adoption focuses on practical visibility benefits rather than aesthetics. Night construction, road work, warehouse operations, and emergency response represent growing application areas. Our industrial clients report 60% higher after-dark mask compliance when providing reflective options, addressing a significant safety concern in 24-hour operations.

Conclusion

Emerging holographic and reflective treatments for safety masks represent a sophisticated integration of optical science, textile engineering, and safety design. These technologies transform ordinary masks into high-visibility safety equipment while creating distinctive visual identities that appeal across market segments. The most successful implementations balance dramatic visual effects with practical performance requirements—maintaining breathability, comfort, and protection while adding valuable visibility features.

As the technology continues evolving, we anticipate further integration of smart elements, improved durability through washing cycles, and more sophisticated optical effects that provide both safety and aesthetic benefits. The convergence of safety and fashion in these treatments creates new opportunities for mask differentiation while addressing genuine safety concerns in low-light conditions.

Ready to explore holographic and reflective treatments for your safety mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our optical treatment capabilities and how we can integrate these advanced technologies into your mask designs while maintaining performance and compliance standards.