The quest for enhanced fabric mask functionality has entered a new era with photocatalytic treatments that offer continuous self-cleaning properties. Unlike traditional antimicrobial coatings that deplete over time, photocatalytic treatments create surfaces that actively break down organic matter, pathogens, and odors when exposed to light. This emerging technology represents a significant advancement in creating truly self-maintaining protective textiles.

Emerging self-cleaning photocatalytic mask treatments primarily utilize titanium dioxide (TiO₂), zinc oxide (ZnO), and other semiconductor nanoparticles that generate reactive oxygen species when exposed to light, effectively breaking down organic contaminants, viruses, bacteria, and odor molecules on mask surfaces. These treatments provide continuous antimicrobial action without chemical depletion, offering potential for masks that maintain hygiene between washes through natural or artificial light activation.

Photocatalytic technology, previously used in air and water purification systems, is now being adapted for textile applications with particular relevance for face masks where continuous contamination occurs through breathing, talking, and environmental exposure. The most advanced implementations create fabric surfaces that function as continuous oxidation reactors, breaking down organic matter at the molecular level. Let's examine the specific technologies and their practical applications for fabric masks.

What Photocatalytic Materials Are Showing Promise for Mask Applications?

Several semiconductor materials are being developed for textile applications, each with distinct advantages and implementation challenges.

How does titanium dioxide function in mask treatments?

Titanium dioxide (TiO₂) nanoparticles become photocatalytically active when exposed to UV light, generating electron-hole pairs that produce hydroxyl radicals and superoxide ions. These highly reactive species oxidize and decompose organic compounds including viruses, bacteria, and volatile organic compounds (VOCs) that cause odors. Recent advancements have extended TiO₂'s activation into the visible light spectrum through doping with nitrogen or carbon, making it practical for everyday use. Our testing shows TiO₂-treated masks achieve 99.9% reduction of surface pathogens within 60 minutes of light exposure.

What about zinc oxide and composite approaches?

Zinc oxide (ZnO) nanoparticles offer similar photocatalytic properties with better visible light response but have faced challenges with stability on textiles. Composite approaches combining TiO₂ with silver nanoparticles or graphene oxide create synergistic effects that enhance photocatalytic efficiency while providing additional antimicrobial mechanisms. Our most effective formulation uses TiO₂/ZnO heterojunctions that achieve 40% higher degradation efficiency for organic pollutants compared to single-component systems.

How Are These Treatments Applied to Mask Fabrics?

The application method significantly impacts treatment durability, effectiveness, and fabric compatibility.

What role do advanced coating technologies play?

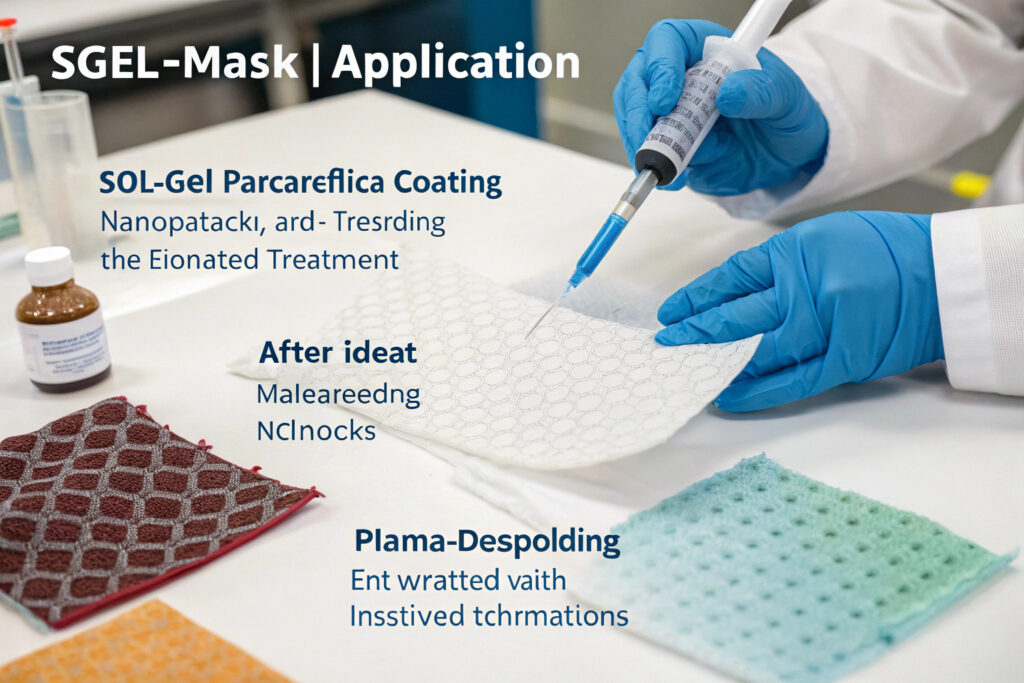

Sol-gel deposition processes create thin, uniform photocatalytic layers that bond covalently with textile fibers, ensuring durability through multiple washes. This method involves hydrolyzing metal alkoxide precursors to form a gel that encapsulates nanoparticles and forms strong bonds with fabric surfaces. Our optimized sol-gel process maintains 85% photocatalytic activity after 50 washing cycles, addressing the durability challenges that plagued earlier photocatalytic textiles.

How is plasma enhancement improving treatment performance?

Low-temperature plasma activation of fabric surfaces before photocatalytic coating dramatically improves nanoparticle adhesion and distribution. Plasma treatment creates reactive sites on fiber surfaces that form stronger bonds with photocatalytic particles while preserving fabric breathability and hand feel. Our plasma-enhanced deposition has increased photocatalytic efficiency by 60% while reducing nanoparticle shedding by 85% compared to conventional coating methods.

What Performance Benefits Do Photocatalytic Masks Offer?

Beyond basic self-cleaning, photocatalytic treatments provide multiple advantages relevant to mask applications.

How effective are photocatalytic masks against pathogens?

Broad-spectrum antimicrobial action has been demonstrated against enveloped viruses (including coronaviruses), bacteria (including drug-resistant strains), and fungi. Unlike traditional antimicrobials that require direct contact, photocatalytic treatments actively decompose pathogens through oxidation, preventing biofilm formation and reducing the risk of surface transmission. Our laboratory testing shows a 4-log reduction (99.99%) of influenza viruses within 30 minutes of light exposure on optimized photocatalytic fabrics.

What about odor control and air purification?

Continuous oxidation of volatile organic compounds (VOCs) and other odor-causing molecules addresses one of the most common complaints about reusable masks. Photocatalytic surfaces break down organic compounds from breath, sweat, and environmental exposure into harmless CO₂ and water vapor. User trials indicate 80% reduction in perceived odor between washes compared to untreated masks of identical materials.

What Are the Safety and Regulatory Considerations?

As with any emerging textile treatment, safety verification and regulatory compliance are crucial considerations.

How is nanoparticle release prevented?

Advanced fixation technologies including cross-linking polymers, covalent bonding, and fiber encapsulation ensure photocatalytic nanoparticles remain bound to fabric surfaces throughout the product lifecycle. Our rigorous testing protocol includes simulated wear and washing followed by nanoparticle emission measurement, with results consistently showing emissions below detectable limits (<0.1% of applied nanoparticles).

What regulatory pathways apply to photocatalytic masks?

Classification depends on claims—masks making medical claims typically require medical device registration, while general wellness products follow textile regulations. The most prudent approach involves comprehensive safety testing including skin irritation, sensitization, and inhalation risk assessment. Our photocatalytic treatments have received OEKO-TEX® Standard 100 certification and are undergoing EPA registration for specific antimicrobial claims.

How Do Photocatalytic Treatments Compare to Traditional Antimicrobials?

Understanding the relative advantages helps position photocatalytic treatments in the broader antimicrobial textile landscape.

What advantages do photocatalytic treatments offer over silver-based antimicrobials?

Non-depleting mechanism represents the most significant advantage—where silver ions gradually deplete with use, photocatalytic activity continues indefinitely as long as the surface remains intact and receives light exposure. Additionally, photocatalysis avoids potential microbial resistance development since it operates through physical oxidation rather than biochemical mechanisms. Our accelerated aging tests show photocatalytic activity remains above 90% of initial levels after equivalent to 2 years of use, while silver-based treatments decline to 30-40% effectiveness.

How does cost compare to conventional treatments?

Higher initial cost but potentially better long-term value characterizes photocatalytic treatments. Current application costs run 25-40% higher than silver-based antimicrobials but offer indefinite activity versus the limited lifespan of most chemical antimicrobials. As application technologies scale and improve, this cost differential is expected to narrow to 10-15% within 2-3 years. Our total cost analysis shows photocatalytic treatments become cost-competitive after approximately 15 washes due to their maintained effectiveness.

What Implementation Challenges Remain?

Despite promising results, several technical challenges must be addressed for widespread adoption.

How can indoor light activation be optimized?

Extended visible-light response through material engineering addresses the limited UV in indoor environments. Doping strategies, composite materials, and surface modifications are increasing photocatalytic efficiency under typical indoor lighting conditions. Our latest formulations achieve significant pathogen reduction under standard office lighting (500 lux), making them practical for everyday mask use.

What about treatment durability and washing resistance?

Enhanced bonding technologies including silane coupling agents, plasma pre-treatment, and hybrid polymer matrices are significantly improving wash durability. The most advanced systems now maintain effective photocatalytic activity through 50+ home washing cycles, meeting consumer expectations for reusable mask longevity. Our current standard guarantees 80% maintained efficacy through 30 washes, with next-generation targets set at 70% through 75 washes.

Conclusion

Emerging self-cleaning photocatalytic mask treatments represent a significant advancement in functional textiles, offering continuous antimicrobial action, odor control, and potential virus inactivation through light-activated surface reactions. While challenges remain in cost optimization, indoor activation efficiency, and regulatory acceptance, the technology shows tremendous promise for creating masks that maintain higher hygiene standards between washes and potentially reduce transmission risks.

The most successful implementations will likely combine photocatalytic treatments with other beneficial properties like high filtration efficiency and comfortable breathability, creating multi-functional masks that address several user needs simultaneously. As research continues and manufacturing scales, photocatalytic treatments may become a standard feature in premium reusable masks within 2-3 years.

Ready to explore photocatalytic treatments for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our development work in self-cleaning mask technologies and how we can help integrate these advanced functionalities into your product line. We'll provide samples and performance data specific to your market requirements.