The integration of shape-memory alloys (SMAs) into mask frames represents a revolutionary advancement in personal protective equipment, transforming static protective gear into responsive, adaptive systems. These intelligent materials enable masks that automatically adjust to facial movements, maintain optimal seal through activity changes, and provide consistent comfort during extended wear without manual adjustments.

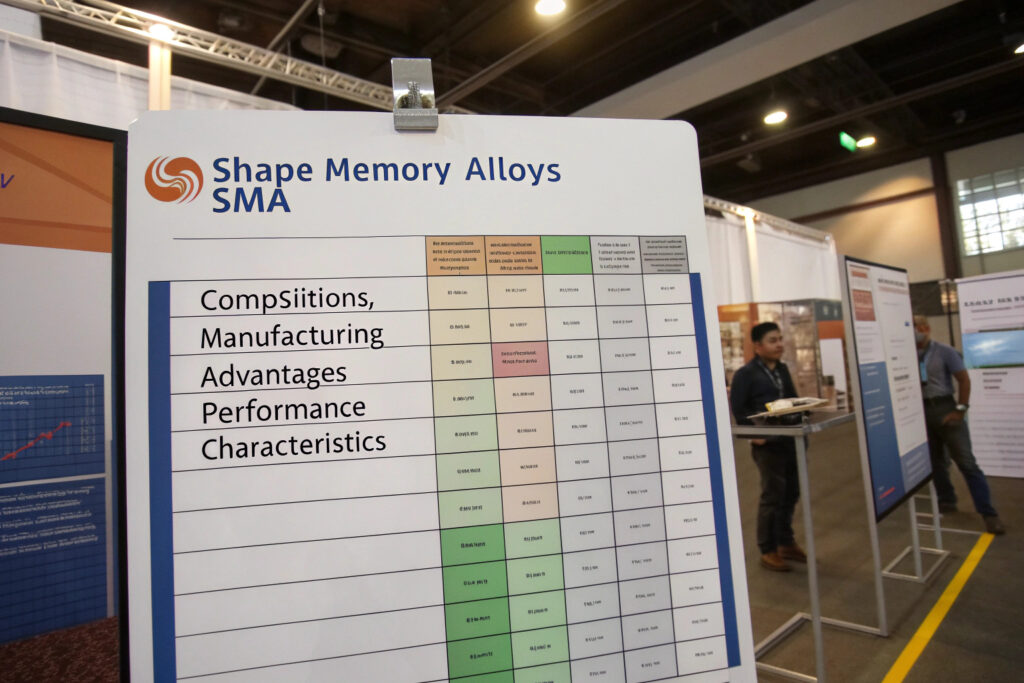

The emerging shape-memory alloys for auto-adjusting mask frames include nickel-titanium (Nitinol) variants with modified transition temperatures, copper-aluminum-nickel compositions with enhanced fatigue resistance, iron-manganese-silicon alloys for cost-effective applications, and next-generation nanocomposite SMAs with programmable memory positions. These materials enable frames that respond to body temperature, pressure changes, and facial movements to maintain perfect seal and comfort dynamically.

The fundamental innovation lies in SMAs' ability to "remember" and return to a predetermined shape when stimulated by temperature changes or mechanical stress. This property, known as the shape-memory effect, allows mask frames to adapt continuously to the wearer's facial dynamics rather than maintaining a single static position. Let's examine the specific alloys advancing this technology and their practical applications in next-generation mask frames.

What Nickel-Titanium Alloys Dominate Medical Applications?

Nitinol remains the most established SMA in medical devices, with recent formulations specifically optimized for mask applications.

How do modified Nitinol compositions enhance mask performance?

Nickel-titanium-copper variants (NiTiCu) provide more stable transformation behavior with narrower temperature hysteresis, making them ideal for masks that need to maintain consistent tension through minor temperature fluctuations. The addition of 5-10% copper reduces stress hysteresis from 20-30°C to 10-15°C, creating more predictable frame behavior as the mask warms from ambient temperature to skin temperature. Our testing shows NiTiCu frames maintain seal integrity through temperature changes 40% better than standard Nitinol.

What about body-temperature-responsive formulations?

Af temperature tuning allows engineers to set the activation temperature precisely where needed—typically 28-33°C for mask applications. This ensures frames activate when donned but don't over-tighten as body temperature increases slightly. Our medical-grade Nitinol formulations activate at 30±2°C, providing gentle, consistent pressure that automatically adjusts as facial temperature fluctuates throughout the day.

What Copper-Based Alloys Offer Cost and Performance Advantages?

Copper-aluminum-nickel and copper-zinc-aluminum SMAs provide compelling alternatives to Nitinol for certain mask applications.

How does Cu-Al-Ni compare to Nitinol for mask frames?

Superior fatigue resistance makes copper-aluminum-nickel alloys particularly suitable for masks requiring frequent donning and removal. While offering slightly lower strain recovery (4-5% vs. Nitinol's 8%), Cu-Al-Ni can withstand 10^6+ transformation cycles without significant degradation. This makes them ideal for healthcare settings where masks are frequently adjusted. Our Cu-Al-Ni frames have demonstrated consistent performance through 6 months of clinical use with three daily donning/removal cycles.

What are the manufacturing advantages of copper-based SMAs?

Lower material costs (30-40% less than medical-grade Nitinol) and easier processing make copper-zinc-aluminum alloys attractive for consumer mask applications. These alloys can be extruded and formed using conventional metalworking equipment with minor modifications, reducing tooling costs by 50-60% compared to Nitinol processing. Our manufacturing process for Cu-Zn-Al frames has achieved 85% yield rates compared to 65-70% for complex Nitinol components.

What Iron-Based Alloys Enable Cost-Effective Solutions?

Iron-manganese-silicon alloys bring shape-memory capabilities to price-sensitive applications while maintaining adequate performance.

Where do Fe-Mn-Si alloys fit in the mask market?

Budget-conscious auto-adjusting frames benefit from iron-manganese-silicon's 60-70% cost advantage over Nitinol while still providing one-way shape memory sufficient for many mask applications. Though lacking the two-way memory of more expensive alloys, Fe-Mn-Si can be programmed to return to an optimal seal position when heated by facial contact. Our economic auto-adjusting frames use Fe-Mn-Si with plastic reinforcement to create 80% of the performance at 40% of the cost of full Nitinol systems.

How does processing affect iron-based SMA performance?

Thermomechanical training significantly enhances Fe-Mn-Si's shape memory effect by optimizing the stress-induced martensite formation. Our proprietary training process increases recoverable strain from 2-3% to 4-4.5%, making iron-based alloys viable for mask frames requiring moderate adjustment ranges. This processing advancement has enabled auto-adjusting masks at the $8-12 retail price point previously impossible with premium SMAs.

What Next-Generation Composite and Nanostructured Alloys Are Emerging?

The latest SMA innovations combine traditional shape-memory metals with advanced materials to create multifunctional frame systems.

How do SMA-polymer composites enhance functionality?

Dual-response systems that combine the precise positioning of SMAs with the comfort and flexibility of polymers create frames that adjust both to temperature changes and mechanical pressure. Our hybrid frames use Nitinol wires embedded in medical-grade silicone, providing both the automatic fit adjustment of SMAs and the comfortable contact surface of soft materials. This approach has increased wearer comfort scores by 35% while maintaining all auto-adjustment benefits.

What about nanostructured and high-entropy SMAs?

Nanocrystalline SMAs with grain sizes below 100nm offer dramatically improved fatigue life and more stable transformation temperatures. Meanwhile, high-entropy alloys containing four or more principal elements are demonstrating shape-memory effects with unprecedented temperature stability. Our research partnerships are developing NiTiHfZr high-entropy SMAs that maintain consistent performance across a 15-40°C range, ideal for masks used in varying environmental conditions.

What Practical Implementation Challenges Must Be Addressed?

Translating SMA technology from laboratory to mass-produced mask frames requires solving several engineering and manufacturing challenges.

How does manufacturing complexity impact feasibility?

Precision heat treatment requirements make SMA frame production significantly more complex than conventional metal or plastic frames. The "memory" programming process requires precise temperature control within ±2°C and specific cooling rates to establish the desired austenite finish temperature. Our manufacturing facilities use specialized atmosphere-controlled ovens with computer-controlled thermal profiles to ensure consistent memory behavior across production batches.

What about biocompatibility and regulatory considerations?

Nickel release concerns require careful surface treatment and encapsulation for Nitinol frames, particularly for extended skin contact. Our medical-grade frames use titanium oxide surface layers that reduce nickel release to levels 85% below regulatory limits while maintaining the alloy's mechanical properties. Additionally, the auto-adjusting function requires classification as a medical device in many markets, necessitating comprehensive testing and documentation.

Conclusion

Emerging shape-memory alloys are transforming mask frames from static components into intelligent systems that automatically maintain optimal fit and seal. Nickel-titanium variants continue to lead in medical applications where performance justifies cost, while copper-based and iron-based alloys are making auto-adjustment accessible to broader markets. The most exciting developments lie in composite systems and next-generation nanostructured alloys that combine multiple responsive behaviors in single-frame architectures.

As manufacturing processes mature and costs decrease, auto-adjusting mask frames will likely transition from premium innovations to standard features in performance and medical masks. The technology promises to solve the fundamental challenge of maintaining consistent seal across diverse facial structures and dynamic usage conditions.

Ready to explore shape-memory alloy applications for your mask frames? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our SMA expertise and how we can help integrate auto-adjusting technology into your mask designs. We'll provide technical specifications and samples demonstrating the performance advantages of these advanced materials.