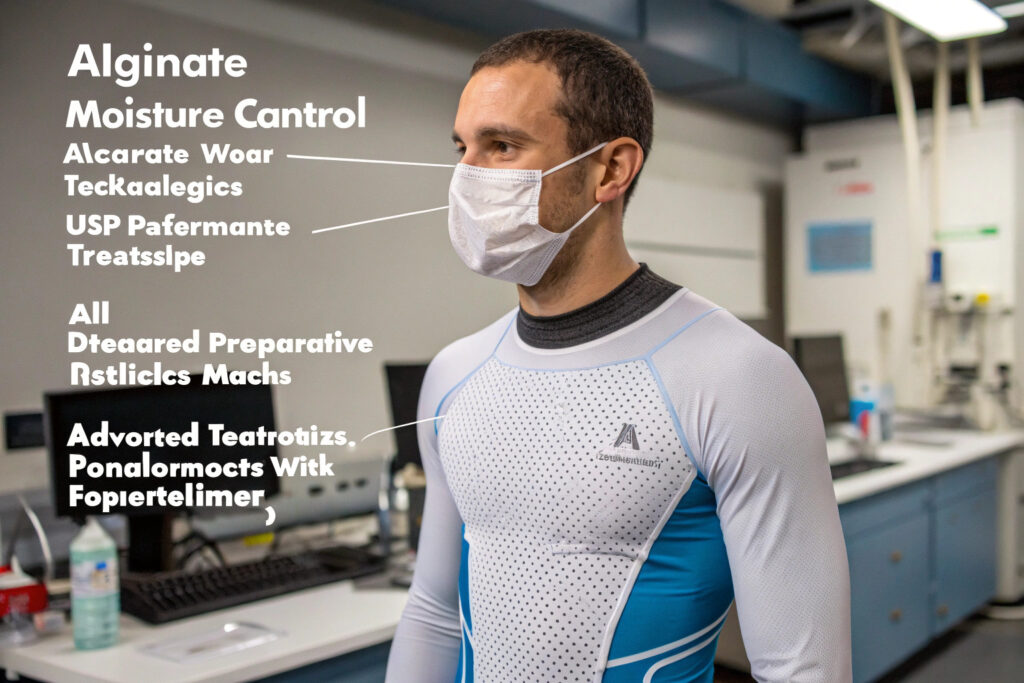

The management of moisture and humidity within wearable interfaces has long been a fundamental challenge in textile science and personal protective equipment design. Alginate-based moisture control technologies represent a significant advancement in this field, leveraging natural biopolymers to create sophisticated, responsive systems that actively regulate the microclimate between the skin and fabric. For manufacturers of high-performance athletic wear, medical dressings, and advanced masks, understanding these latest developments is crucial for creating products that deliver superior comfort and functionality.

Alginate-based moisture control technologies utilize the unique hygroscopic, gel-forming, and ion-exchange properties of alginate—a natural polysaccharide derived from brown seaweed—to create smart textile treatments, coatings, and composite materials that dynamically absorb, store, and release moisture vapor in response to environmental conditions and physiological needs. These systems go beyond simple wicking to provide intelligent humidity buffering, preventing both excessive dryness and clammy dampness. The latest innovations focus on enhancing alginate's native properties through chemical modification, nano-engineering, and integration with other functional materials to create multi-responsive systems.

The global market for smart moisture management textiles is projected to reach $4.3 billion by 2027, with bio-based materials driving significant innovation. Research in Advanced Materials Interfaces demonstrates that engineered alginate composites can achieve moisture vapor transmission rates (MVTR) exceeding 3500 g/m²/24h while maintaining excellent liquid barrier properties—a combination previously difficult to attain. For applications where extended wear comfort is critical, these technologies offer transformative potential. Let's explore the most significant recent developments in alginate-based moisture control.

What Advanced Chemical Modifications Enhance Alginate Performance?

While native alginate has excellent moisture absorption properties, researchers have developed chemical modifications to tailor its behavior for specific applications, particularly in response to pH and ionic strength changes common in sweat.

How Do Cationic Modifications Improve Sweat Interaction?

Native alginate is anionic due to its carboxylate groups. By introducing cationic groups (e.g., through reaction with compounds containing quaternary ammonium salts), researchers create amphoteric alginates that can interact more effectively with the complex ionic composition of sweat (containing Na⁺, K⁺, Ca²⁺, Cl⁻).

- Enhanced Ion-Exchange Capacity: This allows the material to not only absorb water but also selectively trap salt ions, reducing the electrolyte concentration in the retained moisture and mitigating the sticky, salty residue feeling.

- Tunable Swelling Behavior: The swelling ratio (how much water is absorbed) can be precisely controlled by the degree of cationization and the surrounding ionic environment.

Studies published in Carbohydrate Polymers show that cationically modified alginates can increase moisture absorption capacity by 30-50% compared to native alginate in simulated sweat conditions.

What is the Benefit of Grafting Thermoresponsive Polymers?

Grafting polymers like poly(N-isopropylacrylamide) (PNIPAM) onto the alginate backbone creates a smart material with a lower critical solution temperature (LCST).

- Below LCST (~32°C): The grafted chains are hydrophilic and extended, promoting high moisture absorption and a cool, hydrated feel.

- Above LCST (near skin temperature): The PNIPAM chains collapse and become hydrophobic, causing the material to contract and release stored moisture vapor more rapidly through increased porosity.

This creates a self-regulating system that increases breathability precisely when the wearer is hot and sweating, providing dynamic comfort. This technology is at the forefront of adaptive sportswear research.

What Nanostructuring and Composite Approaches Maximize Efficiency?

The physical architecture of alginate within a textile coating or fiber dramatically impacts its moisture control performance. Advanced processing techniques are creating nano-engineered structures with unprecedented surface area and responsiveness.

How Do Alginate Aerogels and Nanofiber Membranes Work?

- Alginate Aerogels: Created by freeze-drying alginate solutions, these ultra-lightweight, highly porous (90-99% air) solids have enormous internal surface areas. When used as an interlining or composite layer, they act as a super-sponge and moisture vapor buffer. They can absorb vast amounts of moisture vapor without feeling wet, and their open nanoporous structure facilitates extremely high MVTR. Research from institutions like Empa has demonstrated alginate-calcium aerogels with MVTRs over 4000 g/m²/24h.

- Electrospun Nanofibers: Alginate can be electrospun into nanofiber mats (fiber diameters 100-500 nm). These mats combine high porosity for breathability with the moisture-active chemistry of alginate. The nanofibers can be directly deposited onto textiles or used as a standalone membrane. Their small fiber size creates capillary forces that enhance directional moisture transport (wicking).

What are the Advantages of Hybrid Alginate-Zeolite or Alginate-Silica Composites?

By compositing alginate with other moisture-active inorganic materials, synergistic effects are achieved:

- Alginate-Zeolite Composites: Zeolites are microporous aluminosilicates with tremendous water adsorption capacity and can also adsorb odor molecules. In a composite, alginate provides the flexible, gel-forming matrix, while zeolites provide additional moisture and odor capture sites. The composite can be coated onto fabrics for long-lasting freshness.

- Alginate-Silica Composites: Mesoporous silica nanoparticles can be embedded in the alginate matrix. Their rigid pores provide structural support and additional pathways for vapor diffusion, preventing the alginate from swelling shut and maintaining high breathability even when fully hydrated.

What Stimuli-Responsive and "Smart" Release Systems Are Emerging?

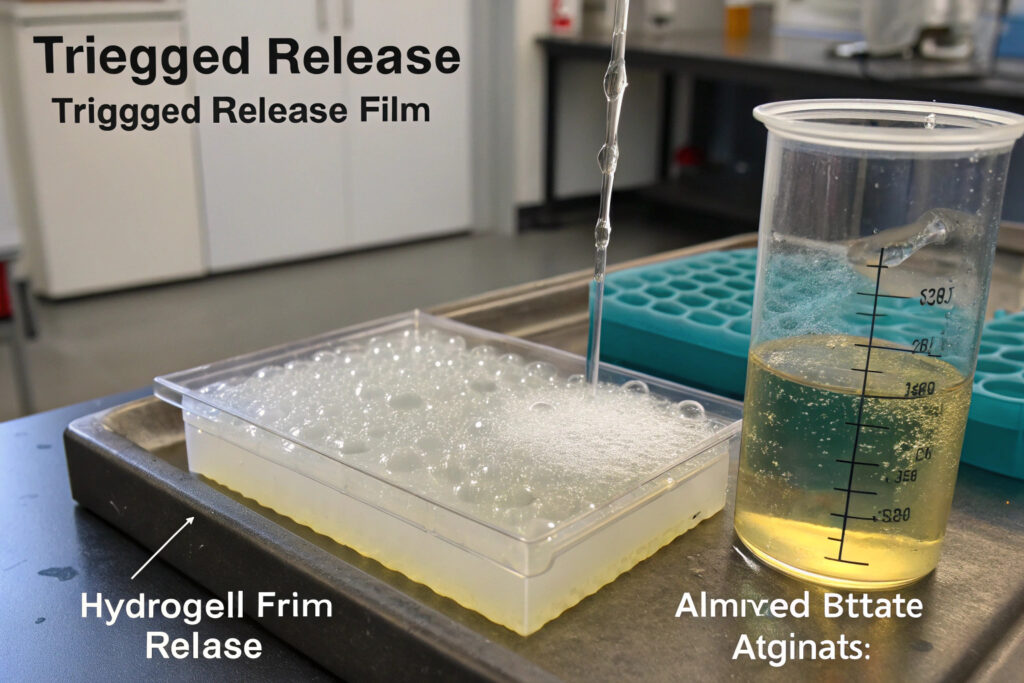

The next generation of alginate technologies moves beyond passive absorption to actively release substances (like cooling agents, antimicrobials, or skin moisturizers) in response to moisture or pH triggers.

How Does pH-Triggered Release Enhance Wearer Comfort?

Human sweat shifts from slightly acidic on resting skin to slightly alkaline during heavy exertion. pH-responsive alginate systems can be designed to release beneficial agents at this specific trigger point.

- System Design: Alginate hydrogels are loaded with microcapsules containing active ingredients (e.g., cooling menthol, soothing aloe vera, or skin-pH-balancing compounds). The hydrogel itself or the capsule wall is engineered to swell and become permeable only when the pH rises to the alkaline range of active sweat.

- Benefit: This ensures that cooling or soothing effects are provided exactly when needed—during peak exertion and sweating—and not wasted during dry periods. This is a key development for athletic masks and performance wear.

Can Moisture Trigger a Cooling Effect Without Electronics?

Yes, through an endothermic reaction release system. Alginate hydrogels can encapsulate solid particles of endothermic salts (like ammonium nitrate or urea). When sweat penetrates the hydrogel, it dissolves the salt, and the dissolution reaction absorbs a significant amount of heat from the immediate surroundings (the skin and fabric), creating a cooling sensation. The alginate matrix controls the rate of water access to the salt, prolonging the cooling effect. This provides a passive, material-based cooling technology for masks and headwear.

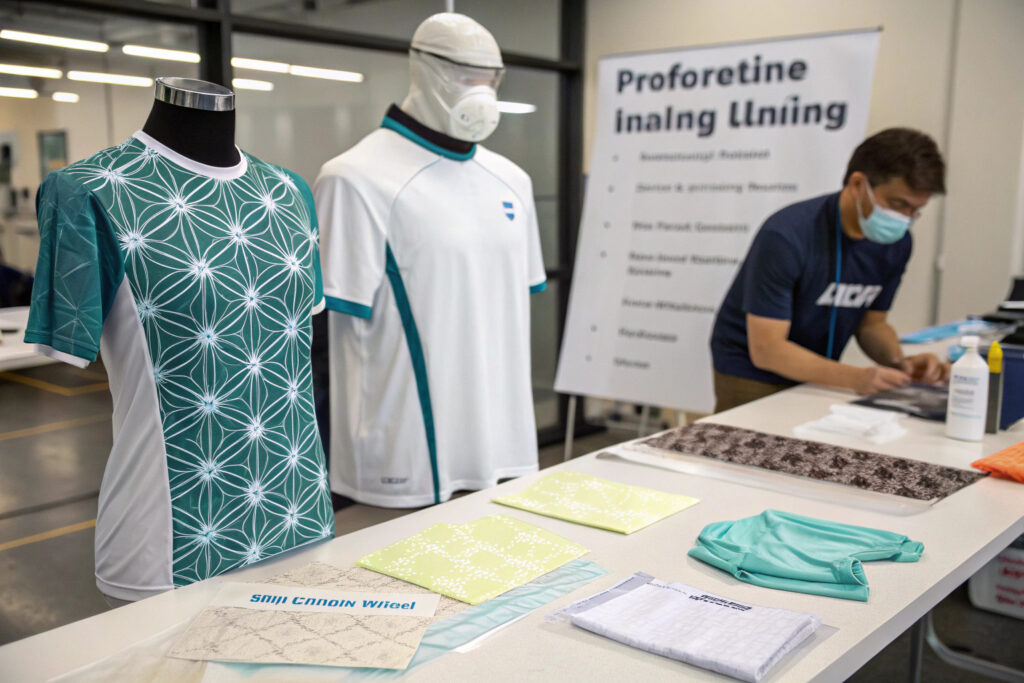

What Are the Key Application-Specific Implementations?

Different products demand tailored implementations of alginate technology, balancing moisture control with other required properties like filtration, durability, and aesthetics.

How Are These Technologies Integrated into Masks for Enhanced Comfort?

For masks, the goal is to manage exhaled humidity and prevent inner-layer saturation. Implementations include:

- Inner Lining or "Comfort Layer": A non-woven fabric bonded with a thin, cross-linked alginate hydrogel coating. This layer absorbs moisture vapor from breath, preventing condensation on the skin and maintaining a drier feel. It can be designed to release the stored moisture between wears as it dries.

- Structured 3D Spacers: Using alginate-based printing or embroidery to create raised 3D patterns on the mask's interior. These structures increase the air gap, provide more surface area for moisture absorption, and keep the potentially damp alginate material slightly away from direct skin contact.

- Composite with Filtration: Alginate nanofibers can be electrospun directly onto meltblown filtration media, creating a monolithic composite where the alginate layer manages moisture while the underlying layer provides filtration.

What Role Do They Play in Medical and High-Performance Textiles?

- Medical Wound Dressings: Calcium alginate fibers are a long-established, superior wound dressing for exuding wounds. The latest advances involve silver-loaded alginate fibers for antimicrobial action or alginate-hyaluronic acid blends to promote healing. The fibers form a soft gel upon absorbing wound exudate, maintaining a moist healing environment.

- Sportswear: In athletic apparel, alginate-based finishes are applied to zones with high sweat production (underarms, back). The latest trend is gradient or patterned application using digital printing techniques, applying more treatment in areas that need it most for optimized weight and performance.

Conclusion

The latest alginate-based moisture control technologies represent a sophisticated leap from simple absorbent materials to intelligent, multi-functional systems. Through chemical modification, alginate's response can be tuned to sweat's specific ionic and pH profile. Through nanostructuring (aerogels, nanofibers), its surface area and breathability are maximized. And through smart composite design, it can be integrated with other materials to provide cooling, odor control, or therapeutic release. For mask manufacturers, these technologies offer a path to solving the perennial comfort issue of humidity buildup, transforming the wear experience. As sustainability drivers increase the demand for bio-based, biodegradable performance materials, alginate's natural origin positions it as a key material for the next generation of advanced textiles.

Ready to explore how the latest alginate-based moisture control technologies can enhance the comfort and performance of your textile products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss material sourcing, finish development, and prototyping for your specific application needs.