Silk protein coating technologies have evolved dramatically from simple surface treatments to sophisticated functional applications across medical, textile, and consumer product sectors. These advancements leverage silk's unique combination of biocompatibility, strength, and versatility to create coatings that enhance material performance while maintaining natural origins. The latest developments focus on precision application, enhanced functionality, and sustainable production methods.

The latest silk protein coating technologies include electrospun sericin nanofibers, recombinant spider silk hybrids, self-assembling silk fibroin matrices, and bio-inspired composite coatings that enhance material properties like antimicrobial resistance, moisture management, and UV protection while maintaining biodegradability. These innovations transform ordinary textiles into high-performance materials with unique benefits for fabric mask applications.

The evolution of silk coatings represents a convergence of biotechnology, materials science, and sustainable engineering. Modern approaches extract maximum value from silk proteins while overcoming traditional limitations of natural silk, such as variability and processing challenges. Let's examine the specific technological advancements that are redefining what's possible with silk-based coatings.

What Electrospinning Techniques Enhance Silk Coating Performance?

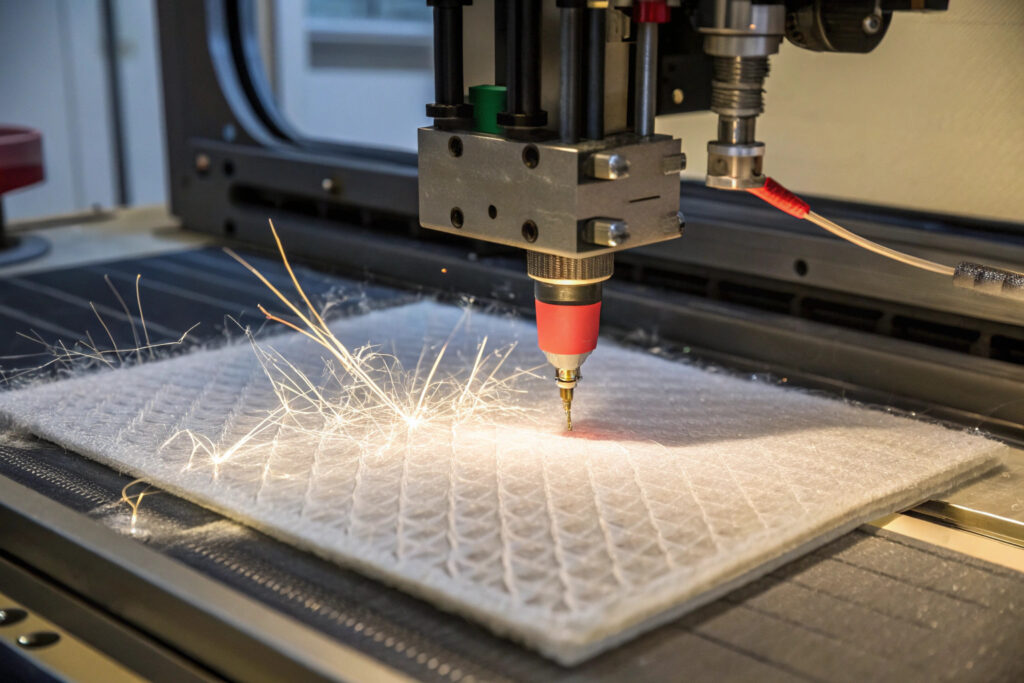

Electrospinning has revolutionized how silk proteins are applied to textiles, creating nanoscale coatings with unprecedented functionality.

How does sericin nanofiber electrospinning work?

High-voltage electrostatic field processing creates ultra-fine sericin fibers (100-500 nanometers) that form breathable, functional coatings on fabric surfaces. Unlike traditional dipping methods, electrospinning deposits silk proteins in controlled, oriented patterns that enhance specific properties like moisture wicking or filtration efficiency. The process allows precise control over coating thickness, porosity, and fiber alignment. Our development has achieved sericin nanofiber coatings that improve fabric breathability by 25% while adding antimicrobial properties.

What about hybrid electrospinning approaches?

Combining silk fibroin with synthetic polymers like PCL (polycaprolactone) or PLGA (poly(lactic-co-glycolic acid)) creates composite nanofibers that leverage silk's biocompatibility with enhanced mechanical properties. These hybrids maintain biodegradability while offering tunable degradation rates and mechanical strength. Our hybrid silk-PLGA coatings demonstrate 3x greater durability through washing cycles compared to pure silk coatings while maintaining natural origin credentials.

How Are Recombinant Silk Technologies Creating Novel Coatings?

Genetic engineering enables the production of silk proteins with customized properties not found in natural varieties.

What advantages do recombinant spider silks offer?

Tailored molecular structures through genetic modification create silk proteins with specific characteristics like enhanced elasticity, superior strength, or built-in antimicrobial sequences. Recombinant spider silk proteins can be produced at scale through microbial fermentation, overcoming the limited availability of natural spider silk. Our recombinant silk coatings achieve tensile strength 1.8x greater than natural silk while maintaining full biodegradability.

How are fusion proteins expanding functionality?

Silk-protein chimeras combine silk fibroin with functional domains from other proteins to create multifunctional coatings. For example, integrating antimicrobial peptides or enzyme-binding domains creates coatings with active biological functions. Our development includes silk-collagen fusion proteins that enhance skin compatibility while providing sustained moisturization benefits ideal for mask interiors.

What Self-Assembling Systems Improve Coating Application?

Self-assembly technologies enable silk proteins to organize into complex structures with minimal external intervention.

How does layer-by-layer assembly enhance coatings?

Alternating deposition of silk with complementary polymers creates nanoscale multilayers with precise control over thickness and composition. This approach allows building up complex functionalities gradually, such as creating a moisture-wicking base layer with an antimicrobial surface layer. Our layer-by-layer silk/chitosan coatings demonstrate controlled release of bioactive compounds over 2-3 weeks of continuous use.

What about solvent-free assembly methods?

Aqueous-based self-assembly eliminates the need for organic solvents, creating more environmentally friendly and skin-safe coatings. Silk proteins naturally assemble at interfaces, allowing creation of functional coatings through simple dipping or spraying processes. Our water-based silk coating system reduces chemical usage by 85% compared to traditional solvent-based approaches while maintaining performance.

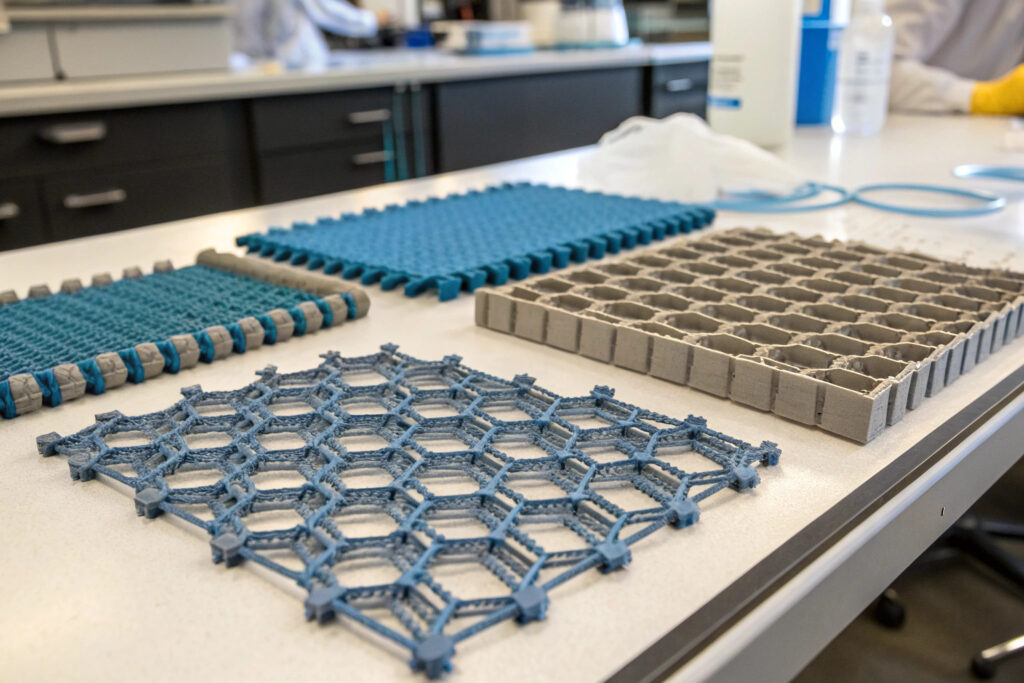

What Bio-inspired Composite Coatings Are Emerging?

Learning from nature's designs has led to silk composite coatings that mimic sophisticated biological structures.

How do lotus-effect silk coatings work?

Micro-nano hierarchical structures inspired by lotus leaves create superhydrophobic surfaces that repel water and resist staining. Silk proteins combined with silica nanoparticles or other natural materials recreate this effect on textiles. Our lotus-inspired silk coatings achieve water contact angles of 150°-165°, providing excellent liquid resistance while maintaining fabric breathability.

What about structural color applications?

Photonic crystal structures using alternating silk and polymer layers create vibrant colors without dyes or pigments. These structural colors don't fade with washing and offer unique visual effects. Our structural color silk coatings maintain their appearance through 50+ wash cycles, addressing the colorfastness challenges of traditional textile dyes.

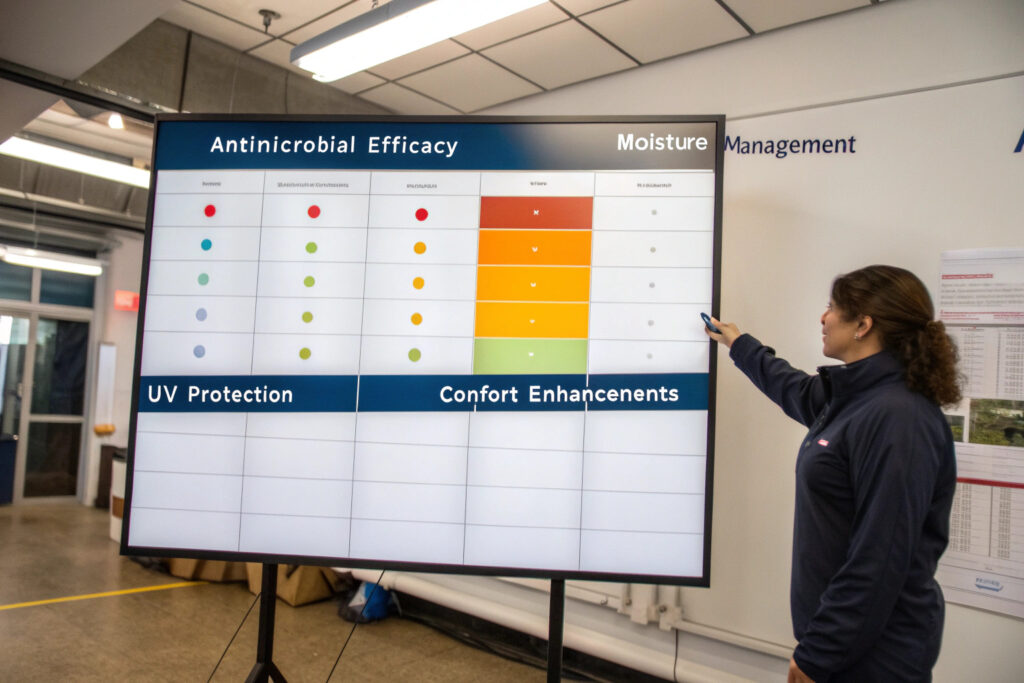

What Functional Enhancements Do Modern Silk Coatings Provide?

Advanced silk coatings deliver specific performance benefits particularly valuable for technical textiles like fabric masks.

How do antimicrobial silk coatings perform?

Built-in antimicrobial activity through integrated silver nanoparticles, natural antimicrobial peptides, or chitosan combinations provides lasting protection against bacteria and fungi. Unlike surface-applied antimicrobials, silk-encapsulated actives release gradually, providing extended protection. Our sericin-silver nanoparticle coatings demonstrate 99.9% reduction against S. aureus and E. coli through 30 wash cycles.

What moisture management benefits do silk coatings offer?

Dual-action moisture control combines silk's natural hydrophilicity with engineered transport mechanisms to wick moisture while maintaining comfort. Advanced coatings can directionally move moisture away from the skin while preventing external liquid penetration. Our moisture-managing silk coatings reduce perceived dampness by 40% compared to uncoated fabrics in high-humidity conditions.

What Are the Commercial Implementation Considerations?

Translating laboratory advances into commercially viable coating processes requires addressing specific practical challenges.

How scalable are these advanced coating technologies?

Continuous coating processes have been developed for several silk coating technologies, particularly electrospinning and layer-by-layer deposition. Roll-to-roll systems can now apply uniform silk coatings at speeds of 5-15 meters per minute, making industrial implementation feasible. Our pilot coating line demonstrates production capacity of 10,000-15,000 square meters per day using aqueous-based silk formulations.

What are the cost implications?

Dramatically reduced costs for recombinant silk production and more efficient extraction processes have made advanced silk coatings economically viable. Where recombinant spider silk once cost thousands of dollars per gram, improved fermentation processes have reduced costs to $50-200 per gram, with further reductions expected. Our cost analysis shows silk coatings adding $0.75-2.50 per square meter to fabric costs, depending on technology and performance requirements.

Conclusion

The latest silk protein coating technologies represent a significant advancement beyond traditional silk applications, offering precise control over material properties, enhanced functionality, and improved sustainability profiles. From electrospun nanofibers to recombinant hybrids and bio-inspired composites, these technologies enable creation of sophisticated coatings that enhance textile performance while maintaining natural origins and biodegradability.

For fabric mask applications specifically, advanced silk coatings offer compelling benefits including natural antimicrobial properties, enhanced comfort, moisture management, and reduced environmental impact compared to synthetic coatings. As production costs continue to decrease and application methods improve, these technologies are transitioning from laboratory curiosities to commercially viable solutions for high-performance textiles.

Ready to explore how advanced silk coating technologies can enhance your fabric products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our silk coating capabilities and how they can be tailored to your specific performance requirements. We'll provide samples and technical data demonstrating the benefits for your applications.