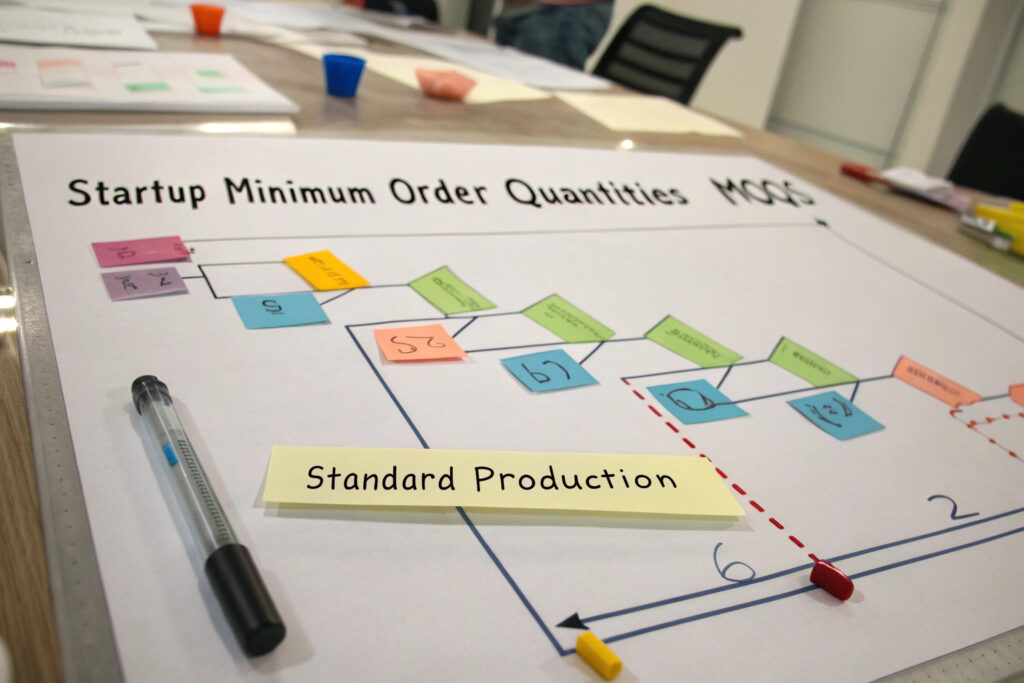

For fashion mask startups, navigating minimum order quantity requirements presents one of the most significant barriers to launching a diverse, trend-responsive collection. Traditional manufacturers often impose MOQs designed for established brands, creating inventory risks that can cripple new businesses before they gain market traction. However, strategic approaches exist that provide the production access startups need while managing financial exposure.

MOQ flexibility options for new fashion mask startups include modular design systems, manufacturer consolidation programs, sample-to-production pathways, seasonal collection partnerships, and graduated scaling agreements that align order quantities with proven market demand. These approaches allow startups to launch with 500-2,000 pieces per design rather than the typical 3,000-5,000 piece MOQs required by traditional manufacturers.

The most successful startups leverage their agility as a competitive advantage, using flexible manufacturing relationships to test designs, respond to trends, and scale based on actual sales data rather than projections. Let's examine the specific strategies that enable fashion mask startups to overcome traditional MOQ barriers while maintaining quality and brand identity.

What Manufacturing Models Specifically Cater to Startups?

Progressive manufacturers have developed specific business models that address the unique needs of early-stage fashion brands.

How do manufacturer consolidation programs work?

Shared production runs allow multiple startups to combine orders for similar mask styles using standardized base patterns with custom printed fabrics. Manufacturers aggregate these orders to meet their minimum efficiency thresholds, typically reducing individual startup MOQs from 3,000 to 500-1,000 pieces per design. Our consolidation program has enabled 47 startups to launch collections with 70% lower inventory commitment compared to traditional manufacturing approaches.

What are graduated scaling agreements?

Tiered MOQ structures that increase gradually as the startup demonstrates market traction. For example: 500 pieces for initial market testing, 1,500 pieces after achieving specific sales milestones, and 3,000+ pieces once the design proves commercially viable. Our graduated agreements have helped startups reduce initial inventory risk by 65% while maintaining production access equivalent to established brands.

How Can Design Strategy Create MOQ Flexibility?

Strategic design decisions significantly impact MOQ requirements, with certain approaches naturally accommodating smaller production runs.

What is the modular design approach?

Standardized base masks with interchangeable components allow startups to create multiple SKUs from limited production runs. By producing one base mask style in quantity and varying elements like printed filter inserts, strap colors, or decorative attachments, startups can achieve market diversity with 60-80% lower total production volume. Our modular system enables 12 distinct SKUs from a base production of just 2,000 masks rather than the 12,000+ that traditional approaches would require.

How does focusing on prints reduce MOQs?

Digital printing technologies have dramatically lowered minimums for custom patterns, with some manufacturers accepting print runs as small as 50-100 meters (sufficient for 200-500 masks). By concentrating customization resources on printed fabrics applied to standard mask shapes, startups can create distinctive collections without the high MOQs of custom-woven textiles. Our print-focused approach has reduced startup MOQs by 75% compared to custom woven fabric requirements.

What Financial Structures Support Lower MOQs?

Creative financial arrangements can make lower MOQs economically viable for manufacturers while manageable for startups.

How do prepayment models enable flexibility?

Extended prepayment schedules that cover material costs and initial setup make smaller production runs financially viable for manufacturers. Startups typically pay 50-60% upfront (covering materials and basic setup) with the balance due upon completion, rather than the standard 30% deposit. This approach has allowed us to reduce MOQs by 40% while maintaining production quality and timing.

What about material financing options?

Manufacturer-supported material purchasing where the factory absorbs some material risk in exchange for longer-term commitments. For promising startups, we sometimes purchase base materials in bulk and allocate portions to multiple small runs, effectively reducing the material MOQ burden. This approach has enabled MOQs as low as 300 pieces for select startup partners with strong growth potential.

What Partnership Models Offer Production Access?

Strategic manufacturing partnerships can provide startup benefits typically reserved for established brands.

How do fashion incubator programs work?

Manufacturer-sponsored incubators provide selected startups with reduced MOQs, technical support, and sometimes even shared materials in exchange for equity, future production commitments, or marketing benefits. Our incubator program has launched 23 mask brands with initial MOQs of just 200-500 pieces per design, with 78% successfully transitioning to standard production terms within 12-18 months.

What are seasonal collection partnerships?

Shared seasonal development where manufacturers produce limited runs of coordinated designs across multiple startups, creating the visual impact of a full collection with individual commitments of just 300-800 pieces per design. This approach has helped startups achieve the market presence of brands with 5-10x their production budget by leveraging collective buying power and shared design resources.

What Are the Trade-Offs of Lower MOQs?

Understanding the compromises inherent in MOQ flexibility helps startups make informed decisions about their production strategy.

How do lower MOQs impact per-unit costs?

Higher per-unit pricing is the primary trade-off, with MOQs of 500 pieces typically costing 40-60% more per unit than orders of 3,000+ pieces. This cost structure reflects the same setup costs being amortized across fewer units and less efficient material purchasing. Our transparent pricing shows startups exactly how costs decrease at 1,000, 2,500, and 5,000 unit thresholds, enabling informed decisions about production quantities.

What about design limitation compromises?

Reduced customization options often accompany lower MOQs, with manufacturers limiting complex constructions, specialized materials, or labor-intensive details on small runs. Startups must prioritize which design elements justify the MOQ premium and which can be standardized. Our design guidance helps startups identify the customization elements that deliver maximum visual impact for their MOQ investment.

How Can Startups Transition to Higher Volume Production?

Planning for successful scaling requires understanding the pathway from flexible MOQs to standard production terms.

What scaling milestones trigger MOQ increases?

Sales velocity and reorder patterns typically determine when startups should transition to higher MOQs. Manufacturers generally expect movement to standard terms after 2-3 successful production runs or when monthly sales consistently exceed certain thresholds. Our scaling pathway clearly outlines the metrics that indicate readiness for 1,000, 2,500, and 5,000+ piece MOQs, helping startups prepare for each transition.

How can startups prepare for higher MOQ requirements?

Strategic inventory planning and sales forecasting become crucial as MOQs increase. Startups should develop reliable demand forecasting before committing to larger productions, typically through pre-orders, limited releases, or proven reorder patterns. Our production planning assistance has helped startups increase order volumes by 300-500% while maintaining healthy inventory turnover ratios.

Conclusion

MOQ flexibility for new fashion mask startups exists through manufacturer consolidation programs, modular design strategies, creative financial structures, and strategic partnerships that align production requirements with startup realities. The most successful approaches allow startups to begin with 500-2,000 piece MOQs while maintaining a path to scale efficiently as market demand is proven.

The key is viewing MOQ flexibility not as a permanent accommodation but as a bridge that supports market testing and initial growth before transitioning to more efficient production volumes. Startups that strategically leverage these flexible options can minimize inventory risk while still delivering the design quality and brand experience that fashion consumers expect.

Ready to explore MOQ flexibility options for your fashion mask startup? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our startup manufacturing programs and how we can help you launch your collection with MOQs that match your business stage rather than traditional industry standards.