Neck gaiters have evolved from simple accessories to versatile face coverings, creating significant private label opportunities across multiple markets. However, navigating minimum order quantity requirements can be challenging, especially for businesses testing new markets or launching limited collections. Understanding the factors that influence MOQs helps you plan your private label strategy effectively while managing inventory risk.

MOQ requirements for private label neck gaiter face coverings typically range from 500-2,000 pieces per design, depending on customization complexity, fabric selection, and printing method. These thresholds balance production efficiency with accessibility for businesses of different scales, though strategic approaches can sometimes reduce these minimums further.

The versatility of neck gaiters—serving as face coverings, headbands, and accessories—creates diverse private label applications from corporate branding to sports teams and retail collections. Let's examine what drives MOQ requirements and how to optimize your order strategy.

What Factors Determine Neck Gaiter MOQs?

Multiple production factors influence minimum order quantities, with customization complexity being the primary driver of quantity requirements.

How does customization complexity affect MOQs?

The more elements you customize, the higher the MOQ typically required. Basic private labeling with simple neck gaiter branding using stock colors and standard fabrics might start at 500 pieces, while fully custom designs with specialized materials, unique printing, and custom packaging could require 2,000-5,000 pieces. Each customization element—fabric development, print screens, label creation, or specialized packaging—requires setup that manufacturers must amortize across your order. Our tiered MOQ system offers progressively lower per-unit costs as customization complexity and order volume increase.

Why does fabric selection impact quantity requirements?

Specialized fabrics often come with higher minimum purchase requirements from mills, directly impacting your MOQ. While basic polyester blends might be available in small quantities, performance fabrics like moisture-wicking technical materials or sustainable options like recycled PET typically have higher thresholds. Our fabric library includes options with varying minimums, allowing us to match clients with materials that fit both their performance needs and quantity constraints.

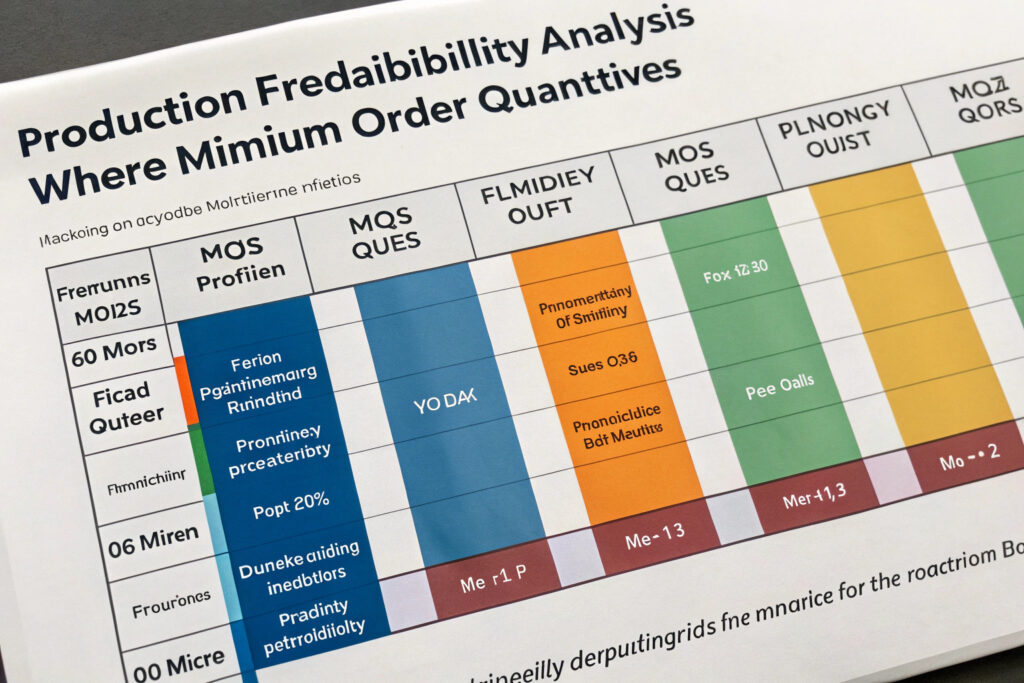

What Are Typical MOQ Tiers for Different Customization Levels?

Understanding standard industry MOQ tiers helps set realistic expectations for your private label project budget and timeline.

What MOQs apply to basic private labeling?

Basic private labeling using stock fabric options with simple logo application typically starts at 500-1,000 pieces per design. This entry level typically includes one-color printing or basic embroidery, standard sizing, and minimal packaging. At this level, you're primarily paying for the setup of your specific branding elements rather than custom product development. Our basic private label program starts at 500 pieces, making it accessible for businesses testing the neck gaiter market or running limited promotions.

How do MOQs increase with advanced customization?

Advanced customization including full-color digital printing, custom fabric development, multiple size options, or specialized packaging typically requires 1,500-3,000 pieces. The increased MOQ reflects additional setup requirements like color matching, pattern development, and manufacturing process adjustments. For businesses committed to creating distinctive products, these higher MOQs deliver more dramatic customization that better reflects brand identity and potentially higher retail margins.

How Can You Reduce or Manage MOQ Requirements?

Several strategic approaches can make private label neck gaiters accessible even with limited order quantities or budget constraints.

What order consolidation strategies work?

Combining multiple products into a single production run can help meet overall quantity thresholds while maintaining variety. Instead of ordering 1,000 pieces of one design, you might order 500 pieces each of two designs that use the same base materials and production processes. This product assortment strategy works particularly well for businesses wanting to offer color variations or slightly different styles without deep inventory in any single option. Our production planning system helps clients optimize their product mix to meet minimums efficiently.

How does strategic design reduce MOQ impact?

Choosing designs that work within standard manufacturing parameters significantly reduces MOQ requirements. Using existing template designs with your branding rather than fully custom patterns, selecting from standard color palettes, and opting for digital printing over screen printing all lower quantity thresholds. We guide clients toward customization choices that deliver maximum brand impact with minimal MOQ penalties, particularly important for market testing or seasonal promotions.

What Production Considerations Impact MOQ Flexibility?

Understanding manufacturing constraints and opportunities helps identify where flexibility exists and where firm minimums are unavoidable.

Where do manufacturers have the least flexibility?

Certain production elements have inherent minimums that manufacturers cannot bypass. Fabric dyeing typically requires minimum lot sizes of 1,000-2,000 meters depending on the dye house, while screen printing requires separate screens for each color that must be amortized across the production run. These technical constraints create natural MOQ thresholds that even the most flexible manufacturers struggle to reduce below certain points. We're transparent about these technical minimums upfront to ensure realistic planning.

Where can creative solutions reduce effective MOQs?

Manufacturers can sometimes offer flexibility through shared production runs where similar orders from different clients are grouped to meet minimums. This approach works particularly well for standard fabric types and basic customization levels. Additionally, using stock components wherever possible—standard packaging, existing fabric inventory, or template designs—can significantly reduce effective MOQs. Our production system identifies these opportunities through ongoing analysis of our production schedule and material inventory.

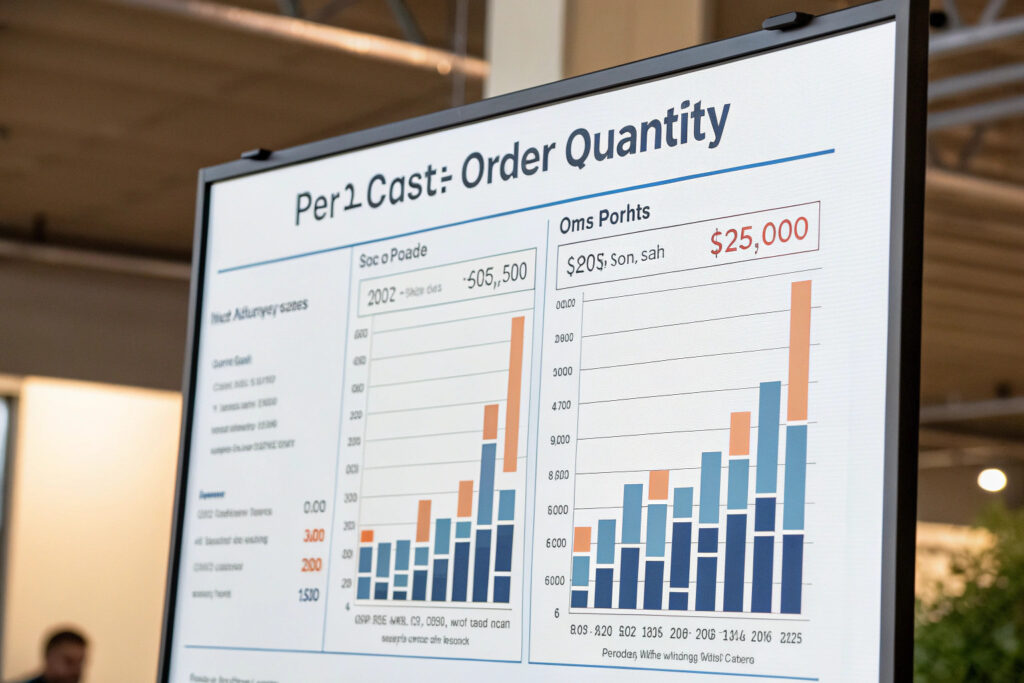

What Are the Cost Implications of Different MOQ Levels?

Understanding how MOQ affects your per-unit cost helps determine the optimal order quantity for your business model and market positioning.

How do costs typically scale with quantity?

Significant price breaks usually occur at 500, 1,000, 2,500, and 5,000 piece thresholds. The cost reduction between 500 and 1,000 pieces might be 15-25%, with another 10-15% reduction at 2,500 pieces. These economies of scale reflect the manufacturer's ability to optimize material purchasing, production line setup, and labor efficiency at higher volumes. Our pricing structure provides transparent cost breakdowns showing exactly how each quantity threshold improves your per-unit economics.

What's the optimal balance between MOQ and risk?

The ideal order quantity balances cost efficiency with inventory risk management. For most businesses, ordering slightly above the minimum threshold (for example, 750 pieces when the MOQ is 500) provides better per-unit costs without excessive inventory commitment. This approach allows for risk-managed scaling while still benefiting from volume efficiencies. Our consultants help clients analyze their specific market capacity and inventory turnover to identify their optimal order quantity beyond basic MOQ requirements.

Conclusion

MOQ requirements for private label neck gaiter face coverings typically range from 500-2,000 pieces, influenced by customization complexity, fabric selection, and printing methods. While these thresholds present challenges for smaller businesses, strategic approaches like order consolidation, smart design choices, and careful timing can make private labeling accessible at various scales. Understanding both the technical constraints and available flexibility helps develop a neck gaiter program that matches your budget, timeline, and market objectives.

Ready to launch your private label neck gaiter collection with MOQs that match your business scale? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our flexible private label options and receive a detailed MOQ analysis for your specific customization requirements. We'll help you find the right balance between customization, quantity, and investment for your market needs.