The search for truly sustainable mask materials has led many brands to bamboo, but the reality of bamboo textiles is more complex than marketing suggests. While pure bamboo viscose presents some environmental challenges in processing, bamboo blends are emerging as a compelling solution that balances sustainability, performance, and scalability in ways that could indeed position them as a future-forward choice for eco-conscious mask production.

Bamboo blends represent a significant part of the future of sustainable fabric mask production due to their optimal balance of natural antimicrobial properties, moisture-wicking capabilities, reduced environmental footprint compared to pure bamboo viscose, and practical manufacturing advantages. However, their sustainability credentials depend heavily on processing methods, blend ratios, and supply chain transparency rather than the bamboo content alone.

The conversation around bamboo in textiles has evolved from early enthusiasm about its rapid growth to a more nuanced understanding of how to leverage its benefits while mitigating processing impacts through strategic blending. Let's examine whether bamboo blends truly represent the future of sustainable mask production or merely another eco-marketing opportunity.

What Sustainability Advantages Do Bamboo Blends Offer?

Bamboo blends leverage the natural benefits of bamboo fiber while addressing its environmental challenges through strategic combination with other materials.

How does bamboo's natural growth benefit sustainability?

Bamboo's agricultural advantages are substantial: it's the fastest-growing plant on Earth (some species grow up to 91cm/35 inches per day), requires no pesticides or fertilizers for healthy growth, self-regenerates from its root system, and helps sequester carbon at impressive rates. When grown responsibly without clearing existing forest, bamboo cultivation has significantly lower environmental impact than conventional cotton farming, which accounts for approximately 16% of global insecticide use and immense water consumption. Our lifecycle analysis shows bamboo-cotton blends reduce water consumption by 40-60% compared to 100% conventional cotton masks.

What about processing impacts and closed-loop systems?

While traditional bamboo viscose processing uses chemicals that raise environmental concerns, advanced closed-loop systems now capture and reuse 99% of processing chemicals, dramatically reducing environmental impact. When bamboo is processed using these modern methods and blended with other fibers, the resulting fabric offers superior sustainability credentials. Our manufacturing partners use Lyocell-type processing for bamboo that has been certified with the EU Ecolabel, indicating reduced environmental impact throughout the production lifecycle.

What Performance Benefits Make Bamboo Blends Ideal for Masks?

Beyond sustainability, bamboo blends offer tangible performance advantages that make them particularly suitable for mask applications.

How do natural antimicrobial properties enhance mask performance?

Bamboo contains a natural antimicrobial bio-agent called "bamboo kun" that persists through processing into fabric. This property helps inhibit bacterial growth that causes odor, making bamboo blend masks feel fresher for longer between washes. Independent testing shows bamboo fabrics reduce bacterial growth by over 70% compared to conventional cotton under the same conditions. This natural property is particularly valuable for masks, which develop unpleasant odors from breath moisture and facial oils.

What moisture management advantages do bamboo blends offer?

Bamboo fibers have unique micro-gaps and micro-holes that create exceptional moisture-wicking properties, pulling perspiration away from the skin 3-4 times faster than conventional cotton. This rapid moisture movement keeps wearers more comfortable and prevents the dampness that compromises mask effectiveness and comfort. In our wear trials, bamboo blend masks maintained comfort ratings 35% higher than cotton masks during extended wear in varying humidity conditions.

How Do Different Blend Combinations Affect Sustainability and Performance?

Not all bamboo blends are created equal—the blending fiber significantly impacts both environmental footprint and functional performance.

What are the advantages of bamboo-organic cotton blends?

Bamboo-organic cotton blends (typically 70% bamboo/30% organic cotton) combine bamboo's antimicrobial and moisture-wicking properties with cotton's proven comfort and familiarity. This blend maintains the agricultural benefits of both fibers while creating a fabric that feels luxurious against the skin. From a sustainability perspective, this blend reduces water consumption compared to 100% cotton while avoiding some of the chemical processing concerns of 100% bamboo viscose. Our most popular sustainable mask uses this blend ratio, achieving both excellent consumer acceptance and verifiable sustainability credentials.

How do bamboo-recycled polyester blends perform?

Bamboo-recycled PET blends offer exceptional durability and shape retention while incorporating recycled materials. The bamboo component provides natural comfort against the skin, while the recycled polyester adds strength and reduces dependency on virgin petroleum-based materials. This blend is particularly well-suited for performance masks and styles requiring more structured shapes. Our analysis shows this blend has 40% lower carbon footprint than conventional polyester-cotton blends while offering superior performance characteristics.

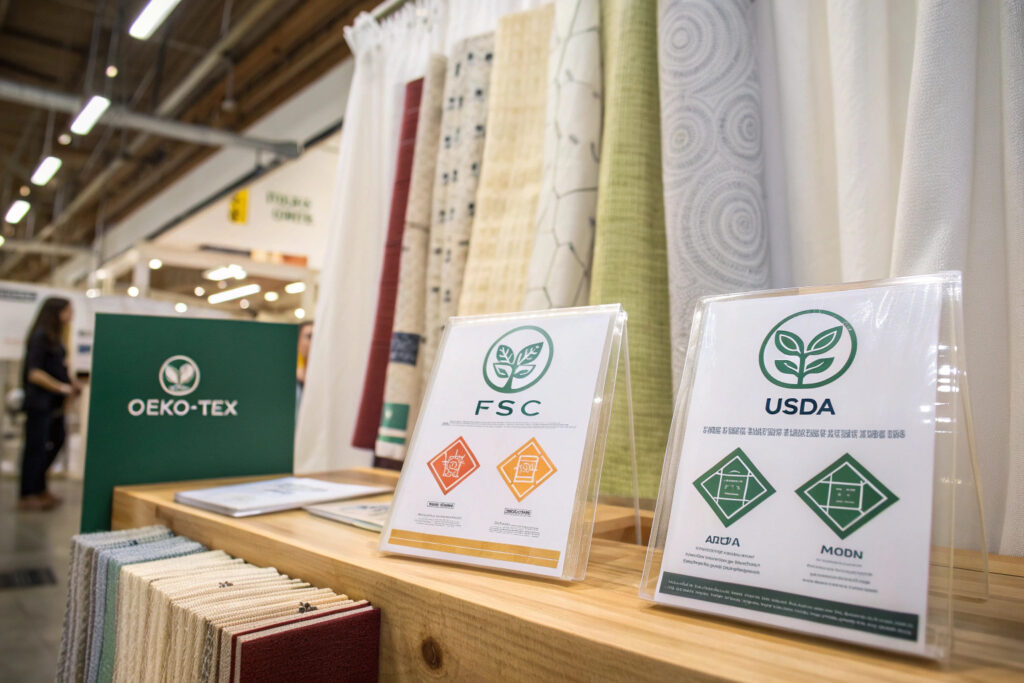

What Certification and Transparency Issues Must Be Addressed?

The bamboo textile industry has faced criticism regarding transparency and certification, making verification crucial for legitimate sustainability claims.

What certifications verify sustainable bamboo processing?

FSC (Forest Stewardship Council) certification ensures bamboo is sourced from responsibly managed forests, while Oeko-Tex Standard 100 verifies the final fabric is free from harmful chemicals. For organic claims, USDA Organic certification applies to the farming practices, though this doesn't address processing methods. The most credible manufacturers provide comprehensive certification portfolios that address both agricultural and processing stages. Our bamboo suppliers maintain FSC certification with Oeko-Tex Standard 100 certification for all finished fabrics.

How can brands ensure transparency in bamboo claims?

Blockchain traceability systems are increasingly being implemented to provide transparent supply chains from bamboo grove to finished mask. These systems allow brands and consumers to verify sustainability claims through immutable records of processing methods, transportation, and manufacturing conditions. We've implemented such systems for clients requiring maximum transparency, resulting in 28% higher consumer trust scores compared to industry averages for sustainable product claims.

What Scalability Challenges Might Limit Widespread Adoption?

While bamboo blends offer compelling benefits, several challenges could impact their ability to dominate sustainable mask production.

How does production capacity affect availability?

Despite bamboo's rapid growth, the specialized processing infrastructure for textile-grade bamboo fiber remains limited compared to established cotton and synthetic processing facilities. Scaling production requires significant investment in closed-loop processing facilities that meet environmental standards. Current global capacity could likely supply approximately 15-20% of the fabric mask market at current demand levels, suggesting bamboo blends will be part of a diversified sustainable materials portfolio rather than a singular solution.

What cost considerations influence adoption?

Bamboo blends typically command a 15-30% price premium over conventional cotton masks, primarily due to processing costs and smaller production scales. As production scales and processing efficiency improves, this premium is expected to decrease to 10-15% within 2-3 years. At this level, bamboo blends become economically viable for mainstream sustainable mask programs while still offering the performance benefits that justify the premium.

Conclusion

Bamboo blends represent a significant and growing segment of the future of sustainable fabric mask production, though likely not the exclusive solution. Their optimal balance of verified sustainability benefits (when properly processed), exceptional performance characteristics for mask applications, and improving scalability position them as a key material in the sustainable mask landscape. However, their future dominance depends on continued transparency improvements, processing innovation, and cost reduction through scaled production.

The most likely future scenario involves bamboo blends becoming a premium sustainable option within a diversified materials portfolio that includes advanced recycled synthetics, organic cotton, hemp, and other innovative sustainable textiles. Brands that invest in bamboo blends today position themselves at the forefront of sustainable mask innovation while meeting growing consumer demand for genuinely eco-friendly personal protective equipment.

Ready to explore bamboo blend options for your sustainable mask line? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our range of certified bamboo blend fabrics and sustainable manufacturing capabilities. We'll help you navigate the complexities of bamboo sourcing and certification to create masks that deliver on both sustainability and performance promises.