The quest for more functional fabric masks has led many brands to consider waterproof coatings as a potential solution for outdoor activities, rainy conditions, or high-exertion scenarios. While the concept seems promising initially, the practical implementation creates significant trade-offs that impact both performance and wearer comfort. Understanding these trade-offs helps determine when waterproof coatings make sense and when they might create more problems than they solve.

Waterproof coatings are situationally viable for performance fabric face coverings but create significant breathability trade-offs that often outweigh their benefits for most applications. While effective for specific use cases like brief exposure to rain or snow during outdoor activities, they typically reduce comfort and breathability too substantially for extended wear or high-exertion scenarios.

The fundamental challenge lies in balancing the competing requirements of breathability and water resistance—properties that naturally work against each other in textile applications. Let's examine where waterproof coatings work effectively and where alternative approaches might deliver better overall performance.

What Technical Challenges Do Waterproof Coatings Create?

The application of waterproof coatings to mask fabrics introduces several technical challenges that impact both manufacturing consistency and user experience.

How do coatings impact breathability and comfort?

Waterproof coatings work by creating a continuous barrier layer that blocks water molecules from penetrating the fabric. Unfortunately, this same barrier also significantly restricts air flow, increasing breathing resistance and causing heat and moisture to accumulate inside the mask. During physical activity, this can create a hot, humid microclimate that becomes uncomfortable quickly and may lead users to remove the mask entirely. Our testing shows that even "breathable" waterproof coatings like PU membranes reduce air permeability by 40-60% compared to uncoated performance fabrics.

What are the durability concerns with repeated use?

Most waterproof coatings degrade with washing and wear, losing their effectiveness over time. The mechanical action of washing, along with exposure to oils from skin and detergents, can cause delamination, cracking, or peeling of the coating. This creates an inconsistent user experience as the mask's performance changes throughout its lifespan. Additionally, the coating may affect the fabric's hand feel, creating a stiffer, less comfortable material against the skin—a significant concern for facial coverage that requires all-day comfort.

Where Do Waterproof Coatings Actually Make Sense?

Despite the challenges, specific scenarios exist where the benefits of waterproof coatings justify their limitations.

What specific activities benefit from waterproofing?

Waterproof coatings provide genuine value for short-duration outdoor activities where users face intermittent exposure to rain, snow, or water splashes. These include hiking, fishing, skiing, or commuting in inclement weather where the mask needs to repel external moisture for limited periods. In these scenarios, users typically accept reduced breathability as a reasonable trade-off for staying dry during specific weather conditions. Our outdoor performance masks with DWR (Durable Water Repellent) coatings have proven successful for these targeted applications.

How does limited-duration use affect viability?

The negative aspects of waterproof coatings become significantly less problematic during shorter wear periods. For activities lasting 30-90 minutes, the breathability limitations remain manageable for most users, while the water resistance provides meaningful protection. This makes coated masks more viable for specific activities rather than all-day everyday use. The key is setting appropriate expectations about the product's intended use rather than positioning it as a universal solution.

What Are the Practical Alternatives to Full Waterproofing?

For most performance mask applications, alternative approaches often deliver better overall functionality without the significant breathability compromises of full waterproof coatings.

How do water-repellent treatments compare?

DWR (Durable Water Repellent) treatments provide a middle ground by causing water to bead up and roll off the fabric surface without creating a complete barrier. These treatments maintain significantly better breathability than full waterproof coatings while still offering protection against light rain and splashes. Although DWR treatments require periodic renewal (typically after 10-20 washes), they don't suffer from the same dramatic breathability reduction. Our most popular outdoor masks use nano-scale DWR treatments that repel water while maintaining 85-90% of the fabric's original breathability.

Can strategic design replace full coating?

Zoned protection approaches often work better than uniform coating applications. By keeping the critical breathing zone uncoated while applying water resistance to less critical areas, manufacturers can balance protection and comfort more effectively. For example, masks with water-resistant top panels and sides combined with an uncoated front panel maintain better breathability while still protecting against rain entering from above. This approach acknowledges that complete waterproofing is rarely necessary for mask applications.

What Performance Testing Reveals About Coated Masks?

Objective testing data helps quantify the actual performance trade-offs between waterproof coatings and alternative approaches.

How does waterproofing affect breathability metrics?

Standard breathability tests measure air permeability in cubic feet per minute (CFM). Our testing shows that uncoated performance fabrics typically achieve 25-40 CFM, while the same fabrics with waterproof coatings drop to 10-15 CFM—a 50-70% reduction that users definitely notice during exertion. Meanwhile, DWR-treated versions maintain 20-35 CFM, representing a much more acceptable 15-30% reduction. This data explains why users consistently rate DWR-treated masks higher for comfort during active use.

What about moisture vapor transmission rates?

Moisture vapor transmission rate (MVTR) measures how effectively fabrics allow perspiration to escape—a crucial factor for comfort. Waterproof coatings typically reduce MVTR by 60-80% compared to uncoated fabrics, causing humidity to build up inside the mask. This explains the "sauna effect" many users report with fully waterproof masks. By comparison, advanced moisture-wicking fabrics without waterproof coatings can actually improve MVTR through capillary action, moving moisture away from the face more effectively than either coated or standard fabrics.

What Do User Experience and Market Response Indicate?

Ultimately, commercial success depends on how real users respond to waterproof masks in actual use conditions.

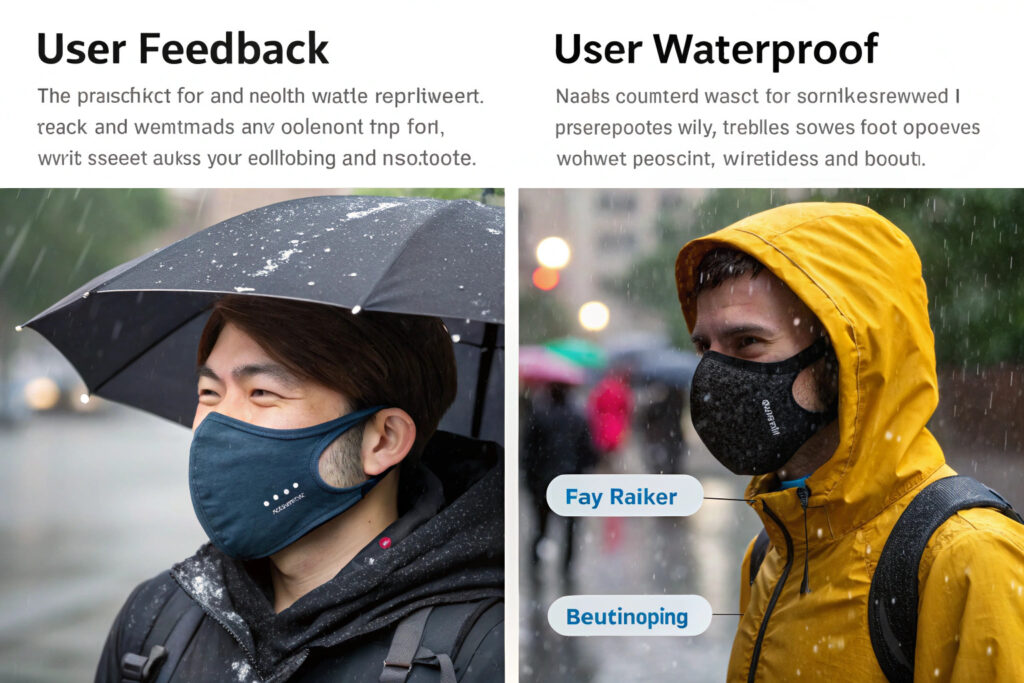

Where has the market responded positively?

The commercial success of waterproof masks has been strongest in specialty outdoor markets where users have specific, understood needs for water protection. Skiers, snowboarders, and coastal activity enthusiasts have demonstrated willingness to accept breathability trade-offs for assured dryness in their specific environments. In these niches, the limited breathability aligns with expected performance characteristics for technical outdoor gear. Our sales data shows strongest adoption in regions with frequent precipitation during outdoor activity seasons.

What user complaints typically emerge?

The most consistent feedback concerns the breathability compromise being more significant than users anticipated. Many purchasers don't fully understand the relationship between waterproofing and breathability until they use the products during actual physical activity. This has led to higher return rates for waterproof masks compared to standard performance versions in our product line. The lesson for brands is that education about performance trade-offs is essential before purchase to manage expectations and reduce post-purchase dissatisfaction.

Conclusion

Waterproof coatings offer situational viability for performance fabric face coverings but present significant breathability trade-offs that limit their appropriateness for general use. They work best for short-duration outdoor activities where water exposure is anticipated but extended high-exertion use isn't expected. For most performance applications, DWR treatments or strategic water-resistant design zones deliver better balance between protection and comfort. The key to successful implementation lies in clearly communicating the intended use case and performance trade-offs to manage user expectations effectively.

Ready to develop performance masks with the right balance of water resistance and breathability for your target market? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our range of fabric technologies and coating options. We'll help you select the optimal approach based on your customers' specific needs and usage scenarios.