When you are ready to launch a new product, time is your most valuable resource. Many buyers struggle with long sample development cycles that delay their entire launch schedule. This can cause lost opportunities, missed seasonal sales windows, and reduced competitiveness in fast-moving markets.

Efficient one-week sample development dramatically accelerates your go-to-market strategy. By reducing waiting times, minimizing design-to-production gaps, and enabling quick decision-making, you can get your products into customers’ hands faster. This approach is especially vital in industries where trends shift rapidly and every week matters.

With the right supplier, one-week sampling not only gives you speed but also ensures accuracy, quality consistency, and reduced risks. Let’s dive deeper into how this process works and why it makes such a difference.

Why Is Speed in Sample Development Critical?

When you compete in global markets, delays can damage your competitive edge. Imagine preparing for a big retail season, only to face setbacks because samples took a month to finalize. That delay can mean missing entire sales cycles.

Fast sample development ensures you meet deadlines, secure buyers’ confidence, and win early purchase orders. Brands that move quickly are the ones that lead in trend-sensitive categories like fashion, masks, and apparel accessories.

How Does Quick Sampling Reduce Business Risks?

Fast sampling reduces uncertainty by giving you early confirmation of fabric quality, fit, and design. Instead of waiting weeks, you can test, adjust, and approve within days. This helps avoid costly last-minute redesigns and late shipments. It also minimizes supply chain risks and prevents your buyers from shifting to faster competitors.

By working with manufacturers who integrate local dyeing, weaving, and finishing, you can also lower the risk of material shortages. That means your entire production stays on track without disruptions caused by delayed sourcing or testing. For global buyers, this reliability is just as important as price.

Can Speed Improve Buyer Trust and Loyalty?

Yes, speed creates confidence. Buyers want to see that their supplier can deliver under pressure. When you present a final sample in one week, you prove your flexibility and capability. This strengthens trust and helps you win repeat orders.

For example, many U.S. and European buyers rely on just-in-time manufacturing to reduce storage costs. If you can support their fast turnaround needs, you become their preferred partner. Once they know you can deliver at speed, they are more likely to expand the scope of orders in the future.

What Role Does Technology Play in Faster Sampling?

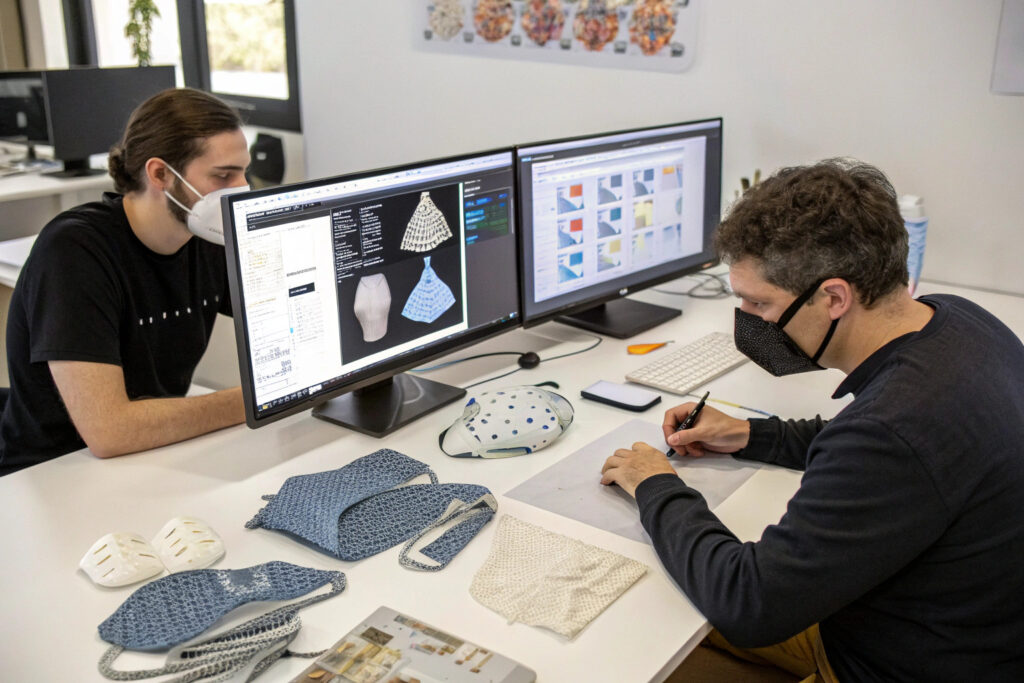

Technology is no longer optional—it is a core enabler of speed. Today, leading factories use digital design, 3D modeling, and AI-driven trend forecasting to reduce development time.

With digital tools, fabric mask prototypes can be visualized, adjusted, and approved before physical production starts. This shortens the iteration cycle and allows brands to make data-backed decisions without losing time.

How Do 3D Prototypes Save Time?

3D samples allow buyers to preview the design, shape, and fit virtually. Instead of waiting for a physical shipment, changes can be made instantly. Many textile innovators are adopting this approach to accelerate approvals and reduce waste.

With this technology, your one-week sampling promise becomes even more powerful, since physical sampling is combined with virtual confirmation. This also ensures consistency when scaling from small batches to large production.

Can AI Trend Analysis Speed Up Fabric Choices?

AI-powered trend analysis helps manufacturers predict upcoming styles, fabric patterns, and consumer preferences. By preparing these in advance, your supplier can present you with the most relevant sample options. Companies using AI in fashion sourcing already see faster turnaround times because decision-making is based on real-time data instead of guesswork.

This means that when you request a sample, the supplier already knows what designs will likely resonate with your target market. That saves you time and reduces costly trial-and-error.

How Does Speed Impact Large-Scale Production?

Fast samples are only the first step. The real advantage comes when this speed translates into bulk production. A supplier that delivers samples in one week likely has streamlined operations for scaling.

Efficient sampling signals that your manufacturer is capable of mass production without delays. This keeps your inventory flow stable, and helps you meet demand peaks without last-minute stress.

Does Quick Sampling Guarantee Faster Bulk Orders?

Not always, but it is a strong indicator. Suppliers who deliver samples quickly usually have integrated supply chains, advanced testing labs, and reliable logistics. These factors directly influence production lead times.

For example, manufacturers with end-to-end quality control ensure samples match bulk output. This means fewer disputes and smoother scaling. In industries like fabric masks and clothing, avoiding rework is the key to saving both time and money.

Can It Help Optimize Logistics and Delivery?

Yes, because speed at the development stage keeps everything else aligned. Quick sampling ensures that shipping schedules can be locked earlier, reducing risks of missing vessel bookings or peak-season congestion. Reliable suppliers also partner with multimodal logistics hubs to guarantee smooth customs clearance and on-time delivery.

For buyers in the U.S. and Europe, where timeliness and tariff efficiency are major pain points, this integration is critical.

Why Should You Choose a One-Stop Supplier?

Choosing the right partner is just as important as fast sampling itself. A one-stop supplier that manages design, fabric sourcing, production, quality control, and logistics reduces friction at every stage.

Working with a one-stop partner ensures consistency, speed, and better communication. Instead of coordinating with multiple vendors, you rely on one partner who manages the entire chain. This avoids miscommunication and cuts down delays.

How Does One-Stop Service Reduce Costs?

One-stop service lowers costs by consolidating processes. Instead of paying extra for third-party testing, packaging, or logistics, your supplier handles everything in-house. Many global buyers prefer suppliers with vertical integration because it simplifies transactions and ensures accountability.

This also makes financial planning easier. Buyers know upfront the total costs, without unexpected add-ons that often occur when multiple service providers are involved.

Does Sustainability Play a Role in Supplier Choice?

Yes, more and more buyers prefer partners who invest in sustainability. Suppliers with commitments to recycled fabrics and low-carbon production align with global brands’ long-term goals. This is especially important for clients in Europe and North America, where eco-friendly sourcing is a top priority.

A supplier who can offer both fast sampling and green solutions becomes a strategic partner, not just a vendor.

Conclusion

Efficient one-week sample development can transform your product launch timeline. It speeds up approvals, reduces risks, builds buyer trust, and ensures smooth scaling into bulk production. By combining technology, agile supply chains, and one-stop services, you can secure a competitive edge in global markets.

If you are planning to launch your own fabric mask line or apparel collection, we at Shanghai Fumao are ready to help. You can contact our Business Director Elaine at elaine@fumaoclothing.com to start developing your order with confidence and speed.