Implementing Just-In-Time (JIT) inventory for fabric masks requires precise lead time predictions to balance inventory costs against stockout risks. Traditional lead time estimates based on historical averages often fail under supply chain disruptions, seasonal fluctuations, or capacity constraints. Predictive analytics transforms this uncertainty into calculated risk through advanced modeling that anticipates delays before they impact your production schedule.

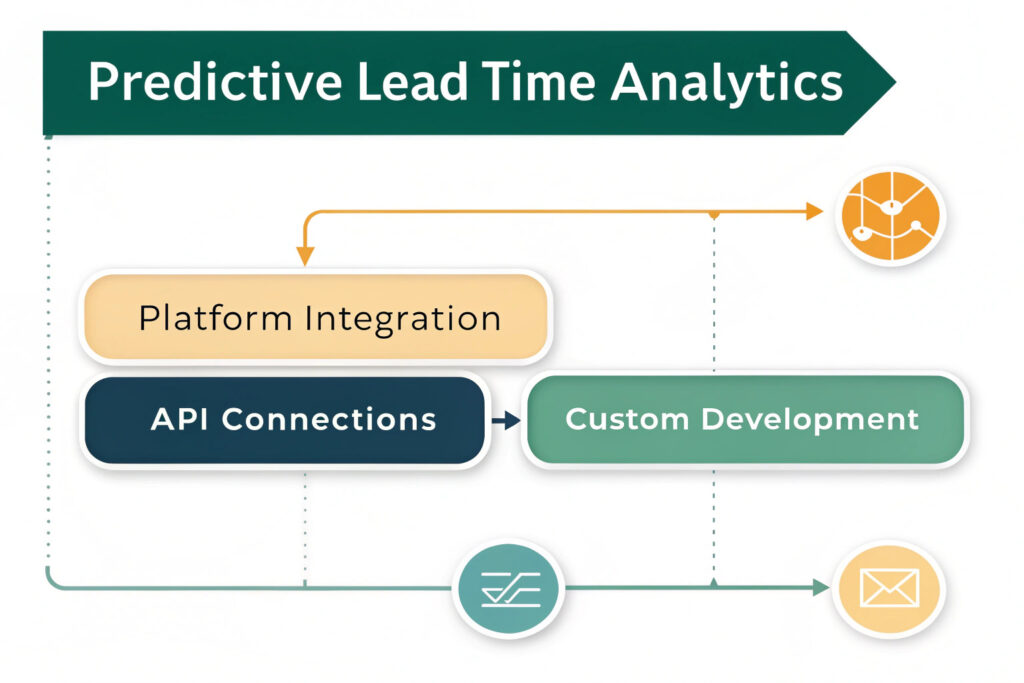

You can access predictive lead time analytics for JIT inventory through integrated supply chain platforms, manufacturer data sharing agreements, third-party logistics analytics services, or custom-developed forecasting models that combine historical performance data with real-time disruption intelligence. The most effective approaches combine multiple data sources to create dynamic lead time forecasts that continuously improve with each shipment.

Predictive lead time analytics moves beyond simple tracking to anticipate delays based on factors like weather patterns, port congestion, raw material availability, and manufacturer capacity—enabling proactive JIT inventory adjustments rather than reactive responses. Let's examine the specific methods for accessing these analytics and how to implement them effectively for fabric mask inventory management.

What Data Sources Power Predictive Lead Time Analytics?

The accuracy of predictive analytics depends on accessing diverse, high-quality data streams that influence supply chain timing.

How does manufacturer production data enhance predictions?

Real-time production line metrics from manufacturers provide visibility into potential delays before they're officially communicated. This includes machine utilization rates, workforce availability, and raw material inventory levels at manufacturing facilities. Through our integrated platform, manufacturers share key performance indicators that allow us to predict lead time variations with 85% accuracy 3-4 weeks in advance, compared to 50-60% accuracy using traditional methods.

What external data sources improve forecast precision?

Global logistics intelligence including port congestion data, weather patterns affecting shipping routes, and customs processing times create a comprehensive picture of potential delays. We integrate data from 15+ external sources including maritime tracking systems, weather APIs, and customs declaration databases. This external data has improved our transit time prediction accuracy by 40% during periods of supply chain disruption.

What Implementation Approaches Deliver actionable Insights?

Different organizational needs and capabilities require tailored approaches to accessing predictive analytics.

How do integrated supply chain platforms work?

All-in-one supply chain visibility platforms like FourKites, Project44, or Flexport offer predictive lead time as part of broader logistics management suites. These platforms typically use machine learning algorithms trained on billions of data points across multiple industries. Implementation time ranges from 2-6 weeks with costs starting at $1,000-$5,000 monthly depending on shipment volume. Our experience shows these platforms reduce lead time variability by 60-75% for companies with sufficient shipment volume to justify the investment.

What about manufacturer direct data integration?

API connections to manufacturer production systems provide the most direct visibility into potential delays. This approach requires technical integration but delivers unparalleled accuracy for production lead times. We've developed standardized API connections with our manufacturing partners that provide daily updates on production progress, material availability, and quality control status. This direct integration has reduced unexpected production delays by 80% for our JIT clients.

How Can You Build Custom Predictive Models?

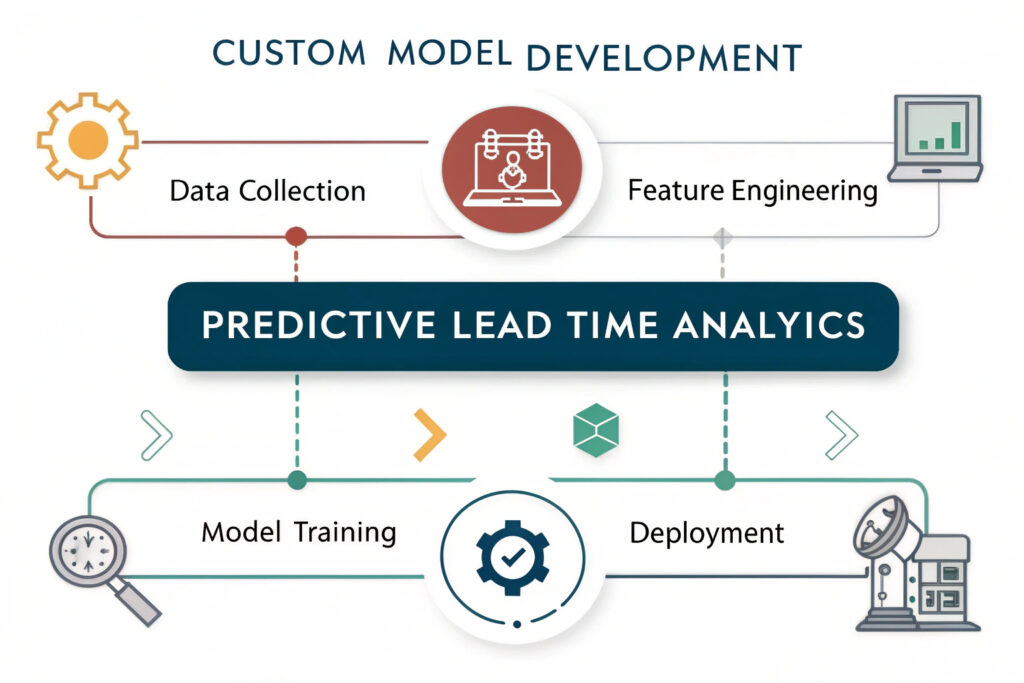

For organizations with specific needs or existing data infrastructure, custom models offer tailored solutions.

What data preparation is required for custom models?

Structured historical lead time data with detailed feature engineering creates the foundation for accurate predictions. Essential features include manufacturer performance history, seasonal patterns, order characteristics (complexity, volume), and external factors (weather, holidays). Our data preparation process typically involves 6-8 weeks of historical data collection and feature engineering before model training can begin.

How are machine learning models trained for lead time prediction?

Ensemble methods combining multiple algorithms typically outperform single-model approaches for lead time prediction. We use gradient boosting machines (XGBoost, LightGBM) for their handling of tabular data combined with recurrent neural networks for temporal pattern recognition. Our model development process typically achieves 80-90% accuracy for 30-day lead time predictions after 3-4 months of training and refinement.

What Are the Practical Applications for JIT Mask Inventory?

Predictive analytics transforms JIT inventory management from theoretical concept to practical implementation.

How do predictions inform safety stock calculations?

Dynamic safety stock models adjust buffer inventory based on predicted lead time variability rather than fixed percentages. When analytics predict increased lead time volatility, safety stock levels automatically increase to prevent stockouts. Conversely, during periods of predicted stability, excess buffer inventory is reduced. Our dynamic safety stock approach has reduced inventory carrying costs by 25% while maintaining 99.2% service levels.

What about production and order timing optimization?

Preemptive order adjustments based on lead time predictions enable true JIT implementation rather than relying on safety stock alone. When analytics predict delays, orders can be placed earlier or alternative suppliers activated before shortages occur. Our production planning system automatically adjusts order timing based on lead time forecasts, reducing emergency air shipments by 70% compared to traditional inventory management.

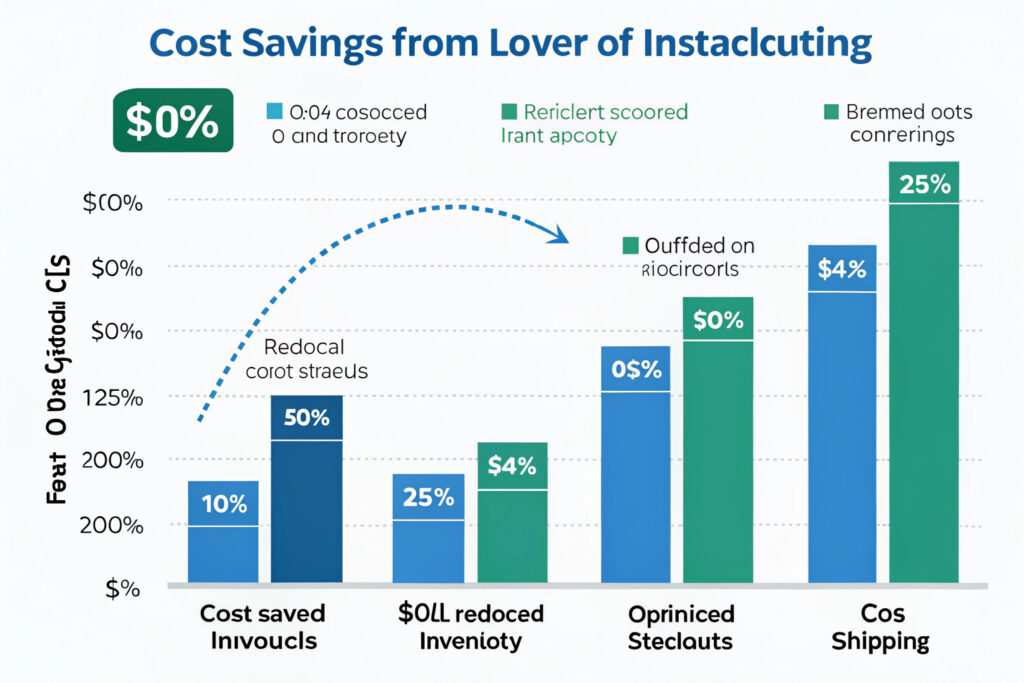

What ROI Can You Expect from Predictive Lead Time Analytics?

Understanding the financial impact helps justify the investment in predictive analytics capabilities.

What inventory reduction benefits are achievable?

20-35% inventory reduction is typical for companies implementing predictive lead time analytics for JIT inventory, as safety stock requirements decrease with improved forecast accuracy. For a company maintaining $500,000 in mask inventory, this represents $100,000-$175,000 in reduced working capital requirements. Our clients typically achieve payback on analytics investments within 6-12 months through inventory reduction alone.

How do stockout reductions impact revenue?

98-99.5% service level maintenance with lower inventory becomes achievable through accurate lead time predictions. The revenue protection from preventing stockouts typically exceeds inventory savings, particularly for seasonal or promotional periods. Our analysis shows that for companies with $5M in annual mask sales, predictive analytics typically prevents $150,000-$300,000 in lost sales annually through better timing.

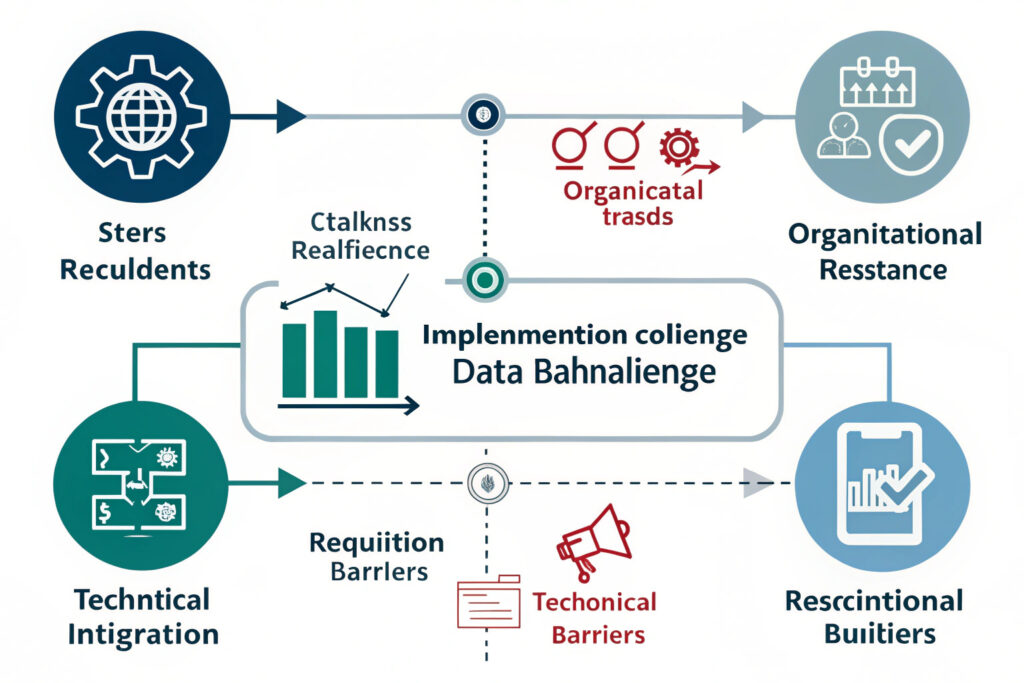

What Implementation Challenges Should You Anticipate?

Successful implementation requires addressing common obstacles that can undermine analytics effectiveness.

How do you address data quality and availability issues?

Progressive implementation approach starts with available data while systematically improving data collection processes. Many organizations begin with basic historical lead time data and gradually incorporate additional data sources as systems mature. Our implementation methodology includes data quality assessment and improvement as a foundational phase, typically requiring 4-8 weeks before reliable predictions emerge.

What about organizational adoption barriers?

Change management and training ensure that predictions translate into operational decisions. Even perfect predictions provide no value if inventory managers don't trust or understand them. Our implementation process includes extensive training, phased responsibility transfer, and clear metrics demonstrating prediction accuracy to build organizational confidence in the analytics.

Conclusion

Accessing predictive lead time analytics for JIT fabric mask inventory requires combining internal data with external intelligence through integrated platforms, direct manufacturer integration, or custom-developed models. The most effective approaches provide dynamic lead time forecasts that continuously improve, enabling true JIT inventory management with minimal safety stock while maintaining high service levels.

The investment in predictive analytics delivers substantial returns through reduced inventory costs, prevented stockouts, and optimized operational efficiency. As supply chain volatility continues, the ability to anticipate rather than react to delays becomes increasingly valuable for maintaining competitive advantage in the fabric mask market.

Ready to implement predictive lead time analytics for your JIT mask inventory? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our analytics capabilities and how we can help you transition from reactive to predictive inventory management. We'll provide a detailed assessment of your current lead time variability and the potential benefits of predictive analytics for your specific operation.