Accessing REACH-compliant dye libraries is crucial for manufacturers exporting fabric masks to the European Union, where chemical regulations are among the world's most stringent. REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) compliance isn't just about avoiding restricted substances—it's about demonstrating due diligence through proper documentation and verification across your entire supply chain. The right dye library provides both the technical color options and the compliance documentation needed for EU market access.

You can access REACH-compliant dye libraries through certified chemical suppliers, specialized textile testing laboratories, industry compliance platforms, and manufacturer partnerships that maintain verified dye inventories with full documentation. The most reliable approaches combine technical color resources with up-to-date regulatory intelligence specific to textile applications.

The challenge extends beyond simply finding compliant dyes to maintaining ongoing compliance as regulations evolve. The most effective solutions provide both the physical dye resources and the verification systems needed to demonstrate compliance to EU authorities and conscious consumers. Let's examine the specific pathways to accessing and implementing REACH-compliant dye libraries for EU-bound mask production.

What Constitutes a REACH-Compliant Dye Library?

Understanding what makes a dye library truly REACH-compliant helps evaluate potential sources and avoid greenwashing.

What documentation should compliant dye libraries provide?

Full substance disclosure sheets listing all chemical components with CAS numbers and concentrations, SVHC (Substance of Very High Concern) statements confirming absence of listed substances, and test reports from accredited laboratories verifying compliance with REACH Annex XVII restrictions. Reputable suppliers provide batch-specific documentation rather than generic compliance statements. Our dye library includes digital access to updated documentation for every dye lot, ensuring traceability from laboratory to finished mask.

How are dye libraries verified for ongoing compliance?

Regular third-party testing and automated regulatory monitoring systems track changes to REACH restrictions and SVHC listings. The most reliable libraries update their compliance status quarterly or whenever new restrictions are announced. Our system includes automated alerts when new substances are added to the SVHC list, with immediate testing protocols to verify continued compliance of our dye inventory.

What Are the Primary Access Channels for Compliant Dyes?

Multiple pathways exist to access REACH-compliant dyes, each with different advantages for various business models.

How do specialized chemical suppliers provide compliance assurance?

EU-based chemical manufacturers and global suppliers with dedicated EU compliance teams typically offer the most reliable REACH-compliant dye libraries. These suppliers invest in the testing and documentation required for EU market access. Our primary dye suppliers include Archroma, Huntsman, and DyStar, who provide comprehensive compliance documentation and technical support for textile applications.

What about compliance platforms and digital solutions?

Digital compliance platforms like SCIP database integration tools and chemical management systems can help identify compliant dyes and track their usage throughout production. These platforms often include databases of pre-verified dyes and automated documentation generation. Our implementation of the Centric Chemicals module has reduced compliance verification time by 70% while improving documentation accuracy.

How Can You Verify Dye Compliance Through Testing?

Independent verification provides crucial protection against supply chain inaccuracies and documentation errors.

What specific tests verify REACH compliance?

Testing for restricted substances listed in REACH Annex XVII including AZO dyes, heavy metals, phthalates, and specific aromatic amines. Additionally, screening for SVHC candidates even before they become restricted demonstrates proactive compliance. Our testing protocol includes full spectrum analysis for 300+ substances, providing comprehensive compliance assurance beyond minimum requirements.

Which laboratories provide recognized REACH testing?

EU-notified bodies and accredited international laboratories with specific expertise in textile chemistry offer the most authoritative testing. Look for laboratories with ISO 17025 accreditation specifically for REACH testing methodologies. Our partnership with SGS, Bureau Veritas, and TÜV SÜD provides testing recognized across all EU member states.

What Are the Cost Implications of REACH-Compliant Dyes?

Understanding the cost structure helps budget for compliance without sacrificing color options or quality.

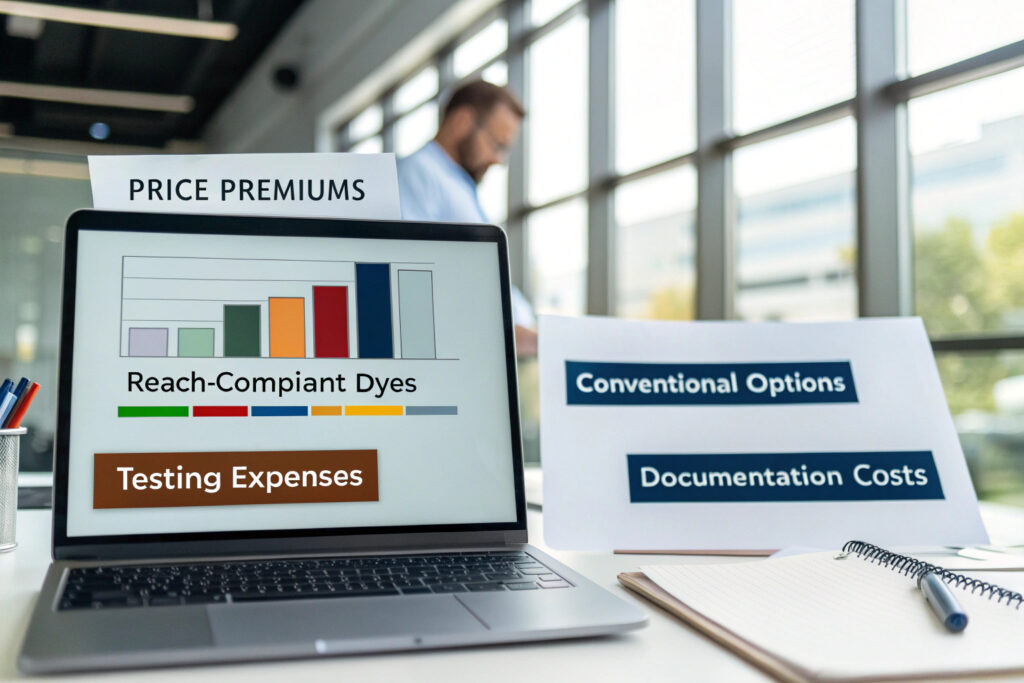

How much more do REACH-compliant dyes cost?

REACH-compliant dyes typically cost 15-40% more than conventional equivalents, with the premium varying based on color complexity and certification level. Basic colors with straightforward chemistry show smaller premiums (15-25%), while complex colors requiring alternative chemistry to replace restricted substances can cost 30-40% more. Our dye cost analysis shows an average 22% premium for full REACH compliance across our color palette.

What testing and documentation expenses should you anticipate?

Comprehensive testing typically costs $800-$2,000 per color depending on the laboratory and scope, while ongoing compliance monitoring adds 3-8% to dye costs. However, these expenses are significantly lower than the potential fines and recall costs of non-compliance. Our compliance program budgets 5-7% of material costs for testing and documentation, which has proven cost-effective compared to compliance failures.

How Do You Implement Compliant Dyes in Mask Production?

Successfully integrating REACH-compliant dyes requires systematic approaches beyond simple substitution.

What production process adjustments might be necessary?

Dyeing parameter optimization may be required as compliant dyes sometimes have different application characteristics than conventional alternatives. Temperature curves, pH levels, and fixation times might need adjustment to achieve color consistency. Our technical team works with dye suppliers to optimize application protocols, ensuring color fastness and consistency while maintaining compliance.

How should documentation flow through production?

Batch-specific compliance documentation should accompany dyes through receiving, storage, mixing, and application stages. Digital tracking systems ensure documentation remains linked to specific production runs. Our QR code tracking system maintains this chain of custody from dye receipt through finished masks, creating an auditable compliance trail.

What Are the Common Compliance Pitfalls and Solutions?

Even with compliant dyes, several implementation challenges can compromise REACH compliance.

How can cross-contamination be prevented?

Dedicated equipment and strict workflow separation prevent contamination between compliant and non-compliant dyes. This includes separate mixing vessels, application equipment, and storage areas. Our facilities use color-coded equipment and documented cleaning protocols between dye lots, eliminating cross-contamination risks.

What about auxiliary chemical compliance?

Comprehensive chemical assessment must include all auxiliary chemicals used in dyeing processes, not just the dyes themselves. Fixing agents, leveling compounds, and other processing chemicals can introduce restricted substances. Our chemical management system evaluates all production chemicals against REACH restrictions, not just primary dyes.

Conclusion

Accessing REACH-compliant dye libraries for EU-bound masks requires a multi-faceted approach combining certified suppliers, independent verification, proper documentation, and systematic implementation. The most successful strategies establish relationships with reputable chemical suppliers, implement robust testing protocols, maintain comprehensive documentation, and continuously monitor regulatory updates. While REACH compliance adds complexity and cost to mask production, it represents essential due diligence for EU market access.

The investment in proper dye compliance not only prevents regulatory issues but also builds brand reputation and consumer trust in markets where chemical safety is increasingly important to purchasing decisions. As EU regulations continue evolving, establishing reliable access to compliant dye libraries becomes increasingly valuable.

Ready to establish REACH-compliant dye resources for your EU-bound mask production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our compliant dye library access and implementation expertise. We'll help you navigate the complexities of REACH compliance while maintaining your color and quality requirements.