The integration of nanomaterial-based sensing technologies into protective equipment represents a significant leap forward in environmental monitoring capabilities. Carbon nanotube (CNT)-based air quality sensors offer unprecedented sensitivity, miniaturization potential, and low-power operation that make them ideal for integration into next-generation masks and wearable monitoring systems. For product developers, industrial safety managers, and healthcare technology innovators, understanding the implementation pathways for these advanced sensors is crucial for creating intelligent protection systems that provide real-time environmental awareness.

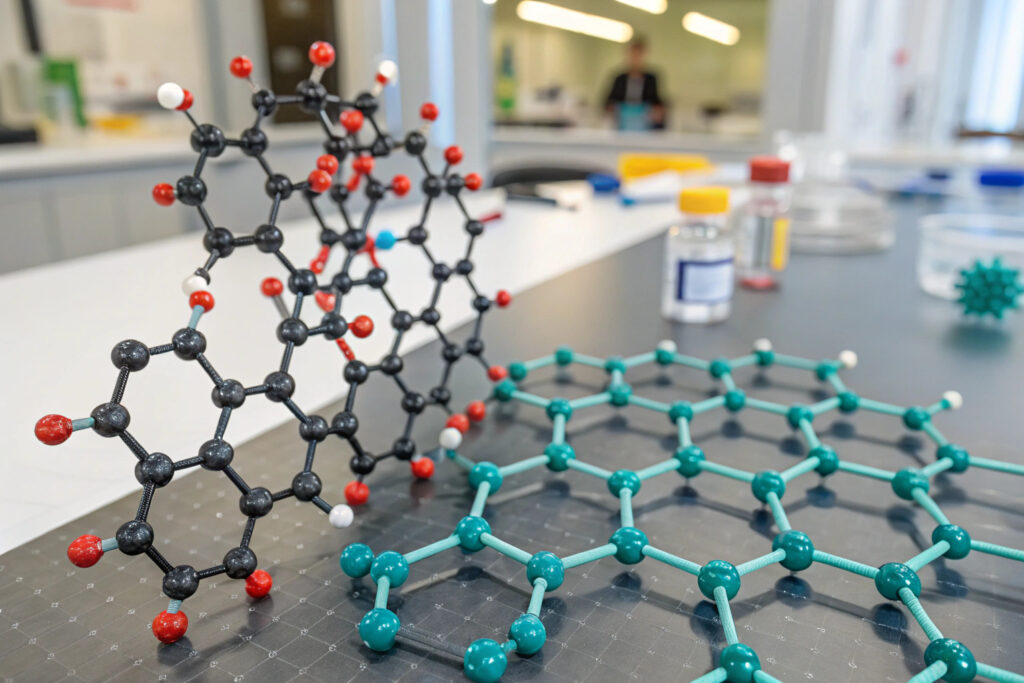

Carbon nanotube-based air quality sensors utilize the exceptional electrical and chemical properties of nanoscale carbon structures to detect and quantify airborne pollutants at part-per-billion (ppb) concentrations with rapid response times, low power consumption, and minimal sensor drift, enabling continuous environmental monitoring within compact wearable formats. These sensors leverage CNTs' high surface area-to-volume ratio, tunable electronic properties through functionalization, and sensitivity to minute surface adsorption events to create detection systems orders of magnitude more sensitive than conventional metal oxide sensors. Successful implementation requires navigating material engineering, sensor fabrication, signal processing, and system integration challenges.

The global CNT market is projected to reach $12.6 billion by 2028, with sensor applications representing one of the fastest-growing segments. Research published in Nature Nanotechnology demonstrates that properly functionalized CNT sensors can detect specific air pollutants at concentrations 100-1000 times lower than conventional sensors while consuming 90% less power. Let's explore the practical implementation considerations for carbon nanotube-based air quality sensor systems.

What CNT Sensor Architectures Offer Optimal Performance?

Different CNT sensor configurations provide varying balances of sensitivity, selectivity, stability, and manufacturing feasibility. Understanding these architectural options enables matching sensor design to specific detection requirements.

How Do Network-Based CNT Sensors Balance Performance and Practicality?

Random network CNT sensors, where nanotubes form percolating networks between electrodes, offer excellent manufacturability and good sensitivity for general air quality monitoring. These networks typically use solution-deposited CNTs that self-assemble into conductive pathways, creating sensors that respond to pollutant adsorption through changes in network resistance. According to research in ACS Nano, optimized network sensors achieve detection limits of 1-10 ppb for gases like NO₂ and NH₃ with response times under 30 seconds. Our implementation uses spray-coated CNT networks with controlled density (typically 10-30 tubes/μm²) that provide optimal trade-offs between sensitivity (resistance changes of 5-20% per 100 ppb) and baseline stability (drift <5%/month).

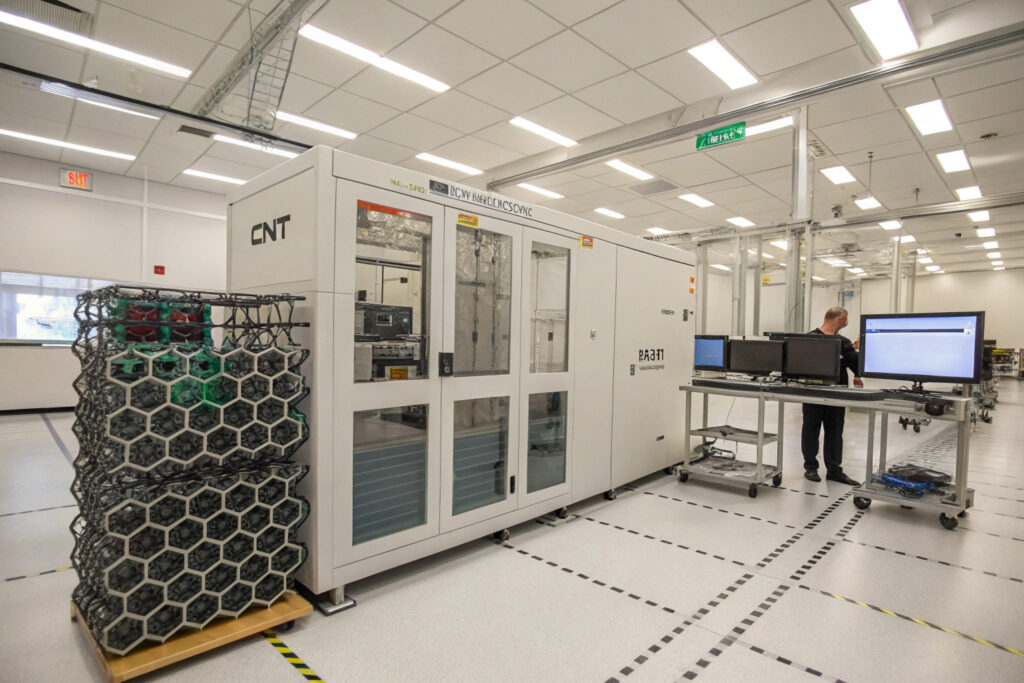

What Advantages Do Aligned CNT Arrays Provide?

Vertically aligned CNT arrays, often called CNT forests, offer superior sensitivity and faster response times due to their ordered structure and maximized surface exposure. These architectures typically achieve 2-5 times higher sensitivity than random networks with response times as fast as 1-5 seconds for some gases. However, they require more complex fabrication processes like chemical vapor deposition with precise growth control. Research from the IEEE Sensors Journal indicates that aligned CNT sensors can maintain consistent performance through 10⁶ measurement cycles with proper encapsulation. Our aligned array implementations use pattern-assisted CVD growth with heights of 10-50 μm, achieving detection limits below 1 ppb for target analytes like formaldehyde and benzene.

What Functionalization Strategies Enable Specific Detection?

Pristine CNTs exhibit limited selectivity, requiring surface functionalization to target specific pollutants while minimizing cross-sensitivity. Different functionalization approaches create chemical recognition sites for different analyte classes.

How Do Polymer Wrappings Create Selective Interfaces?

Non-covalent polymer wrapping preserves CNTs' electronic structure while providing selective interaction sites. Common wrapping polymers include: polyaniline for acidic gas detection, polypyrrole for ammonia and amines, and Nafion for humidity-independent operation. These polymer-CNT composites create sensors that respond to specific analyte classes through swelling, doping, or conformational changes that modulate CNT network conductivity. According to studies in Advanced Functional Materials, properly optimized polymer-CNT sensors achieve selectivity ratios of 50:1 or better between target and interfering gases. Our implementations use electrospun polymer nanofibers containing embedded CNTs, creating hierarchical structures that maximize interaction sites while maintaining mechanical flexibility for wearable integration.

What Role Do Metal Oxide Decorations Play?

Decorating CNTs with metal oxide nanoparticles (typically SnO₂, ZnO, WO₃) creates heterojunctions that enhance sensitivity and enable high-temperature operation for certain applications. The nanoparticles act as catalytic sites that promote specific reactions, while the CNTs provide efficient charge transport pathways. Research in Sensors and Actuators B: Chemical demonstrates that metal oxide-CNT hybrids can achieve ppb-level detection for VOCs with operating temperatures 100-150°C lower than pure metal oxide sensors. Our decoration approach uses pulsed laser deposition to create controlled nanoparticle distributions (typically 5-20 nm particles with 10-30% surface coverage), optimizing the trade-off between sensitivity enhancement and baseline conductivity stability.

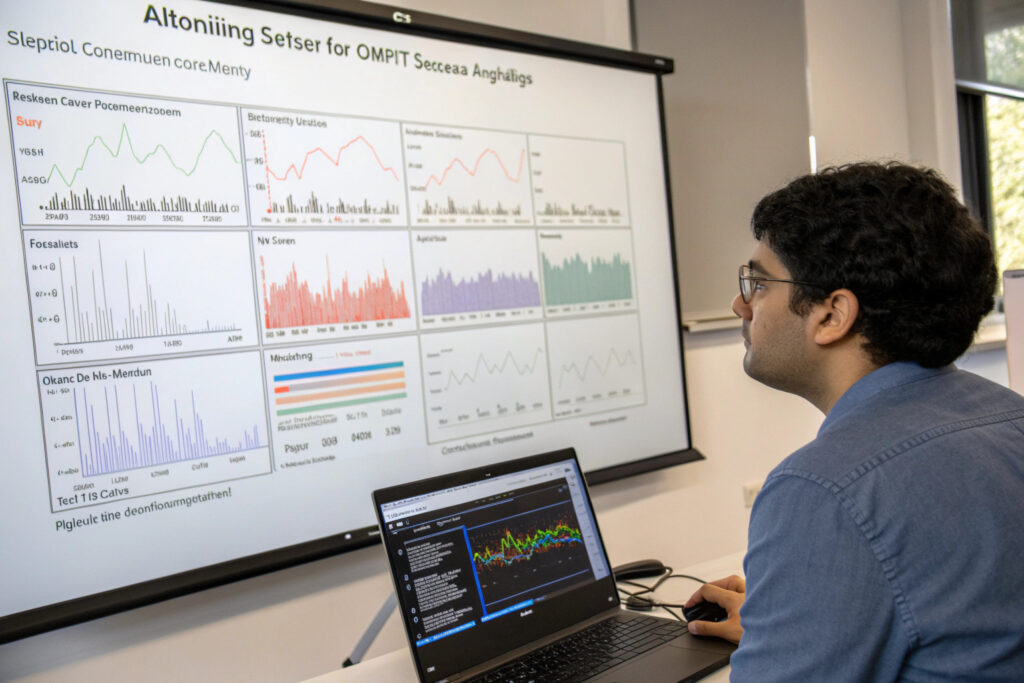

What Signal Processing Approaches Extract Reliable Data?

CNT sensors generate complex signal patterns that require sophisticated processing to extract reliable concentration estimates and compensate for environmental interferences.

How Effective Are Machine Learning Classification Algorithms?

Machine learning algorithms can distinguish between different pollutants based on CNT sensors' multidimensional response patterns (resistance changes, response kinetics, recovery characteristics). Supervised approaches like support vector machines and random forests achieve 85-95% classification accuracy for 5-10 common indoor air pollutants when trained with comprehensive environmental data. According to research in npj Flexible Electronics, properly trained neural networks can maintain accurate classification even with sensor drift up to 20% from baseline. Our implementation uses ensemble methods combining multiple algorithm types, achieving 92% average classification accuracy across 8 target pollutants with false positive rates below 5% for each.

What Compensation Strategies Address Humidity Interference?

Humidity represents the most significant interference for CNT sensors, often causing signal variations comparable to target analyte responses. Effective compensation approaches include: reference sensors with identical CNTs but different functionalization (responding only to humidity), multi-frequency impedance measurements that separate humidity effects from chemical responses, and humidity-controlled sampling systems. Research from the National Institute of Standards and Technology demonstrates that dual-sensor differential approaches can reduce humidity interference by 90-95%. Our preferred method uses paired sensors with hydrophilic and hydrophobic functionalizations, with differential measurements canceling common-mode humidity responses while preserving analyte-specific signals.

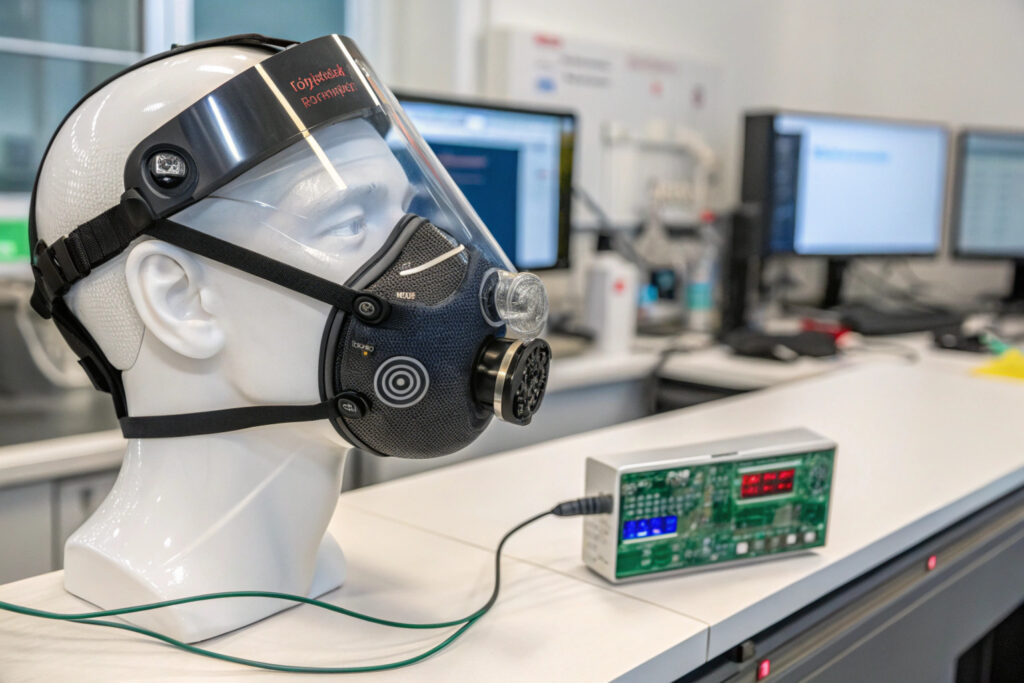

What Integration Methods Enable Wearable Implementation?

Successfully integrating CNT sensors into masks and wearables requires addressing unique challenges related to miniaturization, power constraints, and environmental protection.

How Can Flexible Substrates Accommodate Mask Curvature?

Polyimide and polyethylene terephthalate (PET) substrates with thicknesses of 25-100 μm provide sufficient flexibility for mask integration while maintaining dimensional stability for precise electrode patterning. These substrates typically use inkjet-printed or photolithographically patterned electrodes (gold or platinum) with CNT deposition onto specific sensing areas. According to mechanical testing data from FlexTech Alliance, optimized flexible sensor designs withstand bending radii as small as 2-3 mm for 10,000+ cycles without significant performance degradation. Our implementations use laser-patterned polyimide with integrated strain relief structures at bending points, maintaining sensor functionality through mask donning/doffing and facial movements.

What Micro-Heater Designs Enable Optimal Operation Temperature?

Many CNT sensors require elevated temperatures (50-150°C) for optimal sensitivity and response speed, necessitating integrated micro-heaters. These typically use meander-patterned platinum or nichrome traces with thermal isolation structures to minimize power consumption. Advanced designs achieve operating temperatures of 100-150°C with power consumption of 10-50 mW, compatible with wearable battery systems. Research in Journal of Micromechanics and Microengineering demonstrates that properly designed micro-heaters can achieve temperature stability within ±1°C with pulsed operation strategies reducing average power by 60-80%. Our micro-heater designs use suspended membrane structures with thermal time constants under 100 ms, enabling duty-cycled operation that maintains sensor performance while averaging 5-15 mW power consumption.

What Calibration and Validation Protocols Ensure Accuracy?

Reliable air quality monitoring requires rigorous calibration procedures and ongoing validation to maintain measurement accuracy across diverse environmental conditions.

How Are Multi-Point Calibration Procedures Structured?

Effective calibration requires exposure to multiple known concentrations across the expected measurement range, typically using certified gas standards or calibrated vapor generators. A standard calibration protocol includes: zero gas exposure (establishing baseline), stepwise concentration increases covering 10%, 30%, 50%, 80%, and 100% of measurement range, recovery periods between steps, and verification with intermediate concentrations. According to guidelines from the U.S. Environmental Protection Agency, proper calibration should achieve R² values >0.95 for concentration-response curves with residual standard deviations <10% of measurement range. Our calibration procedures use dynamic dilution systems generating 8-12 concentration points with triplicate measurements at each point, typically achieving R² >0.98 across 0-500 ppb ranges for target pollutants.

What Field Validation Approaches Confirm Real-World Performance?

Field validation compares CNT sensor readings against reference instruments in actual deployment environments over extended periods (typically 2-4 weeks). Key metrics include: correlation coefficients with reference measurements (should exceed 0.85), mean absolute error (should be <15-20% of reading), and data capture rate (should exceed 90%). Validation should cover diurnal cycles, weather variations, and pollutant mixture changes. Our field validation protocols involve co-location with regulatory-grade monitoring stations, with performance assessment including: hour-by-hour comparison, event detection capability evaluation, and interference rejection verification during known pollution episodes.

Conclusion

Implementing carbon nanotube-based air quality sensors requires careful integration of nanomaterial engineering, sensor design, signal processing, system integration, and rigorous calibration. When successfully implemented, these systems provide unprecedented environmental awareness at personal scales, enabling responsive protection and informed decision-making based on real-time air quality data. As manufacturing techniques advance and integration challenges are addressed, CNT sensor technology is poised to transform personal environmental monitoring from occasional sampling to continuous, intelligent assessment.

Ready to explore carbon nanotube sensor integration for your mask products? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how real-time environmental monitoring can enhance your product offerings and provide valuable health protection insights. Our sensor integration team specializes in incorporating advanced sensing technologies into practical, manufacturable wearable systems.