The textile dyeing industry faces mounting pressure to address its significant water consumption and pollution challenges. Conventional dyeing processes can use up to 150 liters of water per kilogram of fabric, with much of this water becoming contaminated with dyes, chemicals, and heavy metals. Closed-loop water recycling systems offer a transformative solution by treating and reusing water multiple times within the dyeing process, dramatically reducing both freshwater consumption and wastewater discharge.

Closed-loop water recycling in dye processes involves capturing, treating, and reusing dye wastewater through advanced filtration and purification technologies, achieving up to 95% water recovery while simultaneously reducing chemical consumption and energy usage. This approach transforms linear "take-make-dispose" water usage into a circular system where water circulates continuously through treatment and reuse cycles. Implementing these systems requires understanding water quality requirements, treatment technologies, and operational adjustments specific to textile dyeing operations.

The global market for textile water recycling is projected to reach $5.2 billion by 2027, driven by regulatory pressures, water scarcity concerns, and corporate sustainability initiatives. Major brands like H&M and Zara have committed to implementing water recycling technologies across their supply chains, creating both requirements and opportunities for forward-thinking manufacturers. Let's explore the practical steps for implementing closed-loop water recycling in dye processes.

What Treatment Technologies Enable Effective Water Recycling?

Selecting the right combination of treatment technologies is crucial for achieving water quality suitable for reuse in dye processes while maintaining color consistency and fabric quality.

How Do Membrane Filtration Systems Remove Dyes and Chemicals?

Membrane filtration technologies, particularly nanofiltration (NF) and reverse osmosis (RO), provide the foundation for effective dye wastewater recycling. NF membranes with pore sizes of 0.001 micrometers effectively remove dye molecules, salts, and organic compounds while allowing water molecules to pass through. According to technical specifications from DuPont Water Solutions, modern NF membranes can achieve 98-99% dye rejection rates while operating at lower pressures than RO systems, reducing energy consumption. The key advantage of membrane systems is their ability to produce consistent water quality regardless of variations in incoming wastewater, ensuring reliable dyeing results. Our implementation uses a multi-stage approach with microfiltration pretreatment to protect downstream NF membranes from fouling.

Can Advanced Oxidation Processes Eliminate Persistent Contaminants?

Advanced oxidation processes (AOPs) using ozone, ultraviolet light, or hydrogen peroxide generate hydroxyl radicals that completely destroy recalcitrant organic compounds that survive conventional treatment. These processes are particularly effective for breaking down complex dye molecules and auxiliary chemicals that can accumulate in closed-loop systems. Research published in the Journal of Hazardous Materials demonstrates that properly optimized AOPs can achieve 95% degradation of persistent dyes within minutes. Our system employs UV-enhanced ozonation that achieves complete color removal while minimizing chemical consumption, ensuring that recycled water doesn't cause unexpected shade variations in subsequent dyeing.

How to Maintain Dyeing Quality with Recycled Water?

The ultimate test of any water recycling system is whether it enables consistent, high-quality dyeing results comparable to those achieved with freshwater.

What Water Quality Parameters Most Affect Dyeing Results?

Maintaining consistent water quality is essential for reproducible dyeing outcomes. The most critical parameters include hardness (calcium and magnesium ions), total dissolved solids (TDS), chloride content, and organic load. Hardness ions can react with dyes to form insoluble complexes, while high TDS can affect dye solubility and migration. According to the American Association of Textile Chemists and Colorists standards, recycled water for dyeing should maintain hardness below 5 ppm, TDS below 50 ppm, and chloride below 10 ppm for most dye classes. Our monitoring system continuously tracks 15 water quality parameters, with automated adjustment systems that maintain optimal conditions for different dye types.

How Does Water Recycling Impact Different Dye Classes?

Different dye classes respond differently to recycled water, requiring specific adjustments to dyeing recipes and processes. Reactive dyes are particularly sensitive to residual salts and organic matter, while disperse dyes show better tolerance to varying water quality. Direct dyes may require additional leveling agents when using recycled water. Research from the Society of Dyers and Colourists provides specific guidance for adapting dyeing processes to recycled water conditions. Our implementation includes comprehensive testing for each dye class, with modified recipes that account for the specific characteristics of our recycled water, ensuring color matching within compared to freshwater dyeing.

What Are the Operational Considerations for Implementation?

Successful implementation requires careful planning of system integration, operational procedures, and staff training to ensure smooth transition and long-term reliability.

How Much Space and Infrastructure Are Required?

Closed-loop water recycling systems typically require significant space for equipment installation, ranging from 100-500 square meters depending on production volume. Key infrastructure requirements include reinforced flooring to support heavy equipment, adequate utility connections (electrical, compressed air, drainage), and appropriate plumbing to connect dyeing machines with the treatment system. The Water Environment Federation's design guidelines provide detailed specifications for industrial water recycling installations. Our implementation used a modular approach that allowed phased installation without disrupting ongoing production, with careful planning to minimize piping runs and energy consumption.

What Training Ensures Proper System Operation?

Comprehensive operator training is essential for maintaining system performance and responding effectively to operational variations. Training should cover normal operations, routine maintenance, troubleshooting common issues, and emergency procedures. Cross-training between dyeing and water treatment personnel ensures better understanding of how process changes affect water quality requirements. Our training program includes classroom instruction, hands-on operation, and regular refresher courses, with certification requirements for key operational roles. This investment has resulted in 95% system uptime and rapid resolution of minor issues before they affect production.

How to Evaluate Economic Viability and ROI?

Understanding the financial aspects of closed-loop water recycling ensures informed decision-making and helps secure necessary investment approvals.

What Cost Savings Can Manufacturers Realistically Expect?

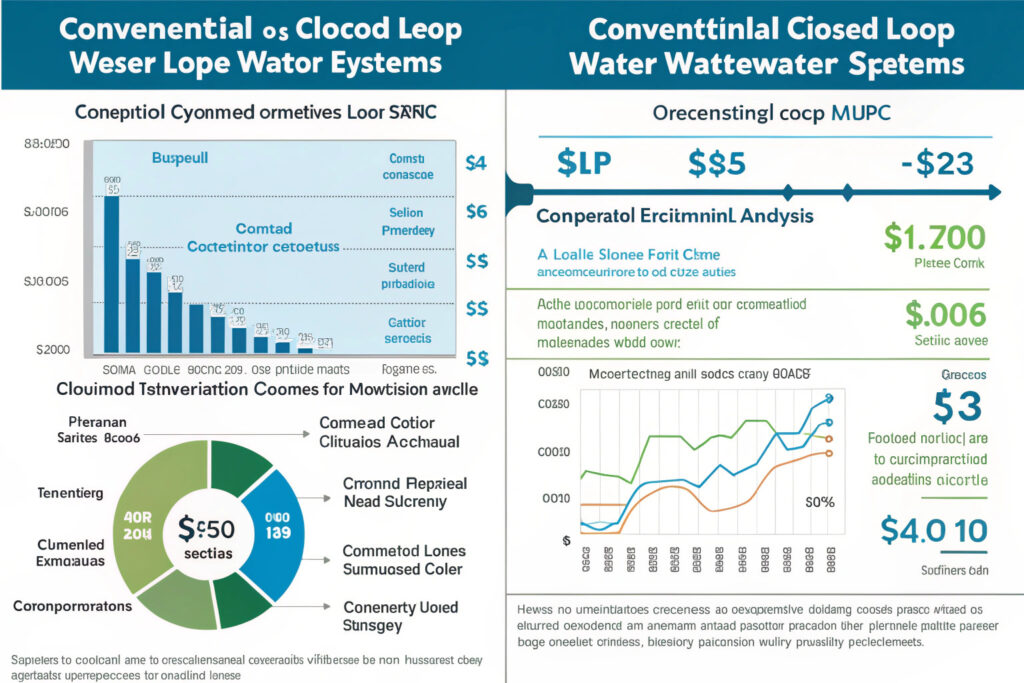

Closed-loop water recycling typically reduces freshwater consumption by 80-95%, wastewater discharge by 90-98%, and thermal energy requirements by 30-50% due to reduced water heating needs. Chemical consumption often decreases by 20-40% through recovery and reuse of unfixed dyes and chemicals. According to case studies from the Zero Discharge of Hazardous Chemicals Foundation, typical payback periods range from 1.5-3 years, with ongoing annual savings of $150,000-$500,000 for medium-sized dyeing operations. Our implementation achieved 92% reduction in water purchasing costs and 85% reduction in wastewater treatment fees, resulting in a 28-month payback period.

How Do Government Incentives Improve Financial Returns?

Many governments and municipalities offer financial incentives for water conservation and pollution prevention, significantly improving project economics. These may include grants covering 20-50% of capital costs, tax credits for environmental technology investments, reduced wastewater treatment fees for facilities implementing recycling, and accelerated depreciation for green equipment. The Environmental Protection Agency's WaterSense program provides information on available incentives in different regions. Our project qualified for a 30% investment tax credit and reduced municipal wastewater charges, improving the payback period by 8 months.

Conclusion

Implementing closed-loop water recycling in dye processes represents a significant but achievable transformation toward sustainable textile manufacturing. By selecting appropriate treatment technologies, maintaining dyeing quality through careful process control, addressing operational requirements, and understanding the economic benefits, manufacturers can dramatically reduce their environmental impact while improving operational efficiency. The transition requires substantial investment and operational changes but delivers compelling returns through reduced resource consumption, lower operating costs, and enhanced market positioning as a sustainable manufacturer.

Ready to explore closed-loop water recycling for your dyeing operations? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss how we can help you implement water recycling technologies that reduce environmental impact while maintaining product quality and improving profitability. Our technical team has direct experience with successful implementations across different dyeing processes and fabric types.