Peak season production delays can cripple your supply chain, causing missed delivery windows, strained customer relationships, and lost revenue. The combination of increased demand, limited raw material availability, and overstretched manufacturing capacity creates a perfect storm that requires strategic planning and proactive management to navigate successfully.

You can mitigate peak season fabric mask production delays through advanced planning, strategic raw material stocking, production capacity reservation, and implementing agile manufacturing principles that increase flexibility and responsiveness. The most effective approach combines pre-season preparation with real-time adaptability to address unexpected challenges as they arise.

Successfully navigating peak season requires understanding both the predictable bottlenecks and the unexpected disruptions that can derail even well-planned production schedules. Let's examine specific strategies that protect your timeline while maintaining quality standards.

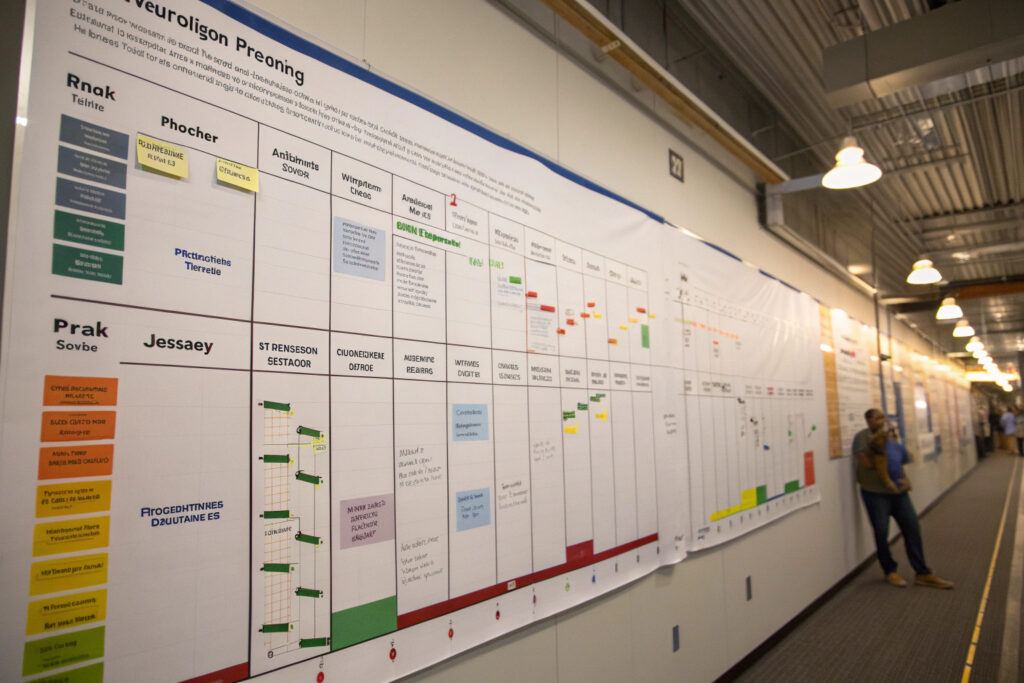

What Advanced Planning Strategies Prevent Delays?

Proactive planning remains your most powerful weapon against peak season disruptions, transforming predictable challenges into managed processes.

How far in advance should you plan for peak season?

Initiating peak season planning 4-6 months in advance provides sufficient time to secure production capacity, order raw materials with longer lead times, and develop contingency plans. Our most successful clients begin their Q4 holiday season planning in June-July, while spring season planning typically starts in December-January. This advanced timeline allows for strategic fabric procurement, especially for specialized materials like organic cotton, antimicrobial textiles, or custom-printed fabrics that may have extended lead times.

What capacity reservation approaches work best?

Production capacity booking with staggered deposits ensures manufacturing slots while managing cash flow. Many manufacturers offer capacity reservation programs where clients place a small deposit (typically 10-20%) to secure production time during peak periods, with the balance due when production commences. This approach has helped our clients avoid the 3-5 week production queue delays that typically occur during September-October and March-April peak periods.

How Can Strategic Inventory Management Buffer Against Delays?

Maintaining strategic inventory at different supply chain stages creates buffers that absorb disruptions without halting production.

What raw materials should you stock in advance?

Identify bottleneck materials with long lead times or single-source dependencies for advance purchasing. For fabric masks, this typically includes specialized elastics, nose wires, custom-dyed fabrics, and branded components like custom woven labels. Maintaining 4-6 weeks of these critical materials prevents production stoppages when supplier lead times extend during peak demand. Our material planning system identifies these critical path items based on historical lead time variability and substitution difficulty.

How does component pre-production help?

Completing subassembly manufacturing during off-peak periods creates semi-finished inventory that can be quickly converted to finished products when orders arrive. This might include pre-cutting fabric components, pre-forming nose wires, or pre-assembling filter pockets before the peak season crunch. This approach can reduce final production time by 40-60%, allowing manufacturers to respond more quickly to last-minute orders and changes.

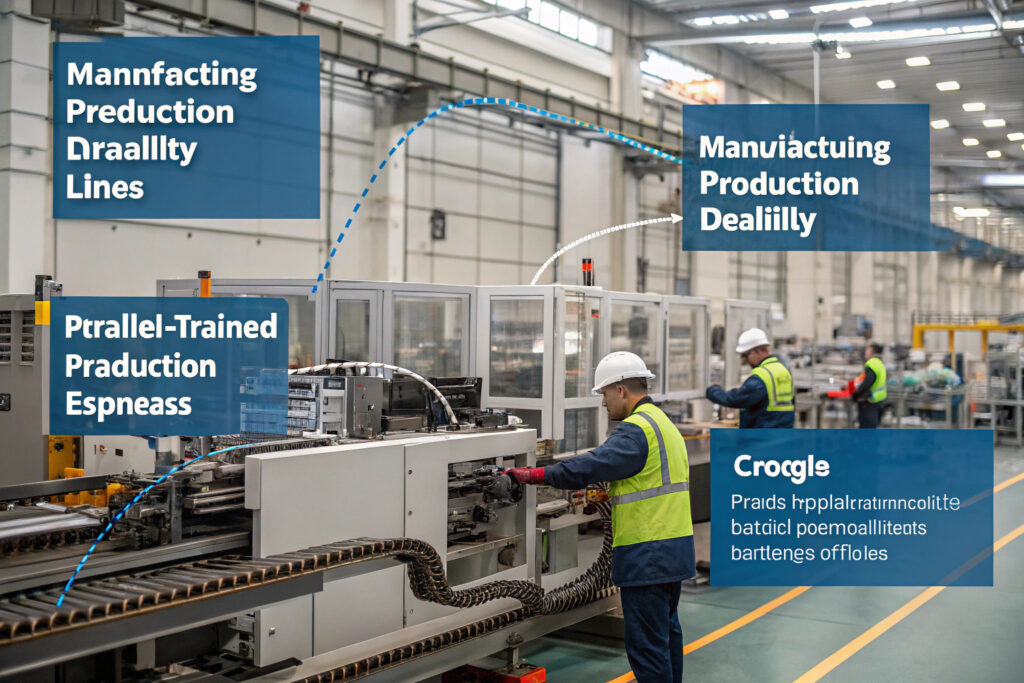

What Manufacturing Flexibility Strategies Reduce Bottlenecks?

Building flexibility into your production approach creates multiple paths to meet deadlines when unexpected issues arise.

How does parallel production work?

Diversifying production across multiple facilities or production lines prevents single-point failures. This might involve splitting large orders between two manufacturing lines or facilities, or maintaining relationships with backup manufacturers for overflow capacity. While this approach requires additional coordination, it provides crucial insurance against equipment failures, labor shortages, or localized disruptions that could otherwise halt all production. Our production network approach has helped clients maintain delivery schedules despite individual facility issues.

What about modular design and production?

Designing masks with standardized components and modular construction enables faster production and easier substitution when specific materials face delays. For example, using the same ear loop attachment across multiple mask styles simplifies production and allows for easier material substitution if a specific elastic type becomes unavailable. This approach reduced peak season delays by 35% for clients who implemented modular design principles.

How Can Supplier Relationships Mitigate Timing Issues?

Strong supplier partnerships often provide preferential treatment during constrained capacity periods, making relationship management a strategic advantage.

What makes supplier partnerships valuable during peak seasons?

Long-term strategic partners typically receive priority allocation during capacity constraints, better payment terms that improve cash flow, and more flexible response to order changes. Manufacturers naturally prioritize clients who provide consistent year-round business over seasonal buyers when making difficult allocation decisions. Our partnered clients receive capacity priority that has reduced their peak season delay risk by 60% compared to transactional buyers.

How does transparent communication help?

Open forecast sharing with manufacturers allows them to plan their capacity, workforce, and material procurement to meet your anticipated needs. While forecasts are never perfect, providing rolling 13-week forecasts with regular updates helps manufacturers allocate resources more effectively. Manufacturers receiving reliable forecasts have demonstrated 25% better on-time delivery performance during peak periods compared to those receiving unexpected surge orders.

What Logistics Strategies Prevent Shipping Delays?

The production timeline means little if finished goods get stuck in transit, making logistics planning an integral part of peak season strategy.

How can you secure timely shipping during peak season?

Advanced freight booking with multiple logistics providers ensures transportation capacity when you need it. Ocean and air freight capacity often becomes constrained during peak manufacturing periods, particularly in August-October. Booking space 4-6 weeks in advance, using a mix of primary and backup carriers, and considering alternative routes (like China-Europe rail for European destinations) provides delivery assurance. Our logistics team typically secures Q4 shipping capacity by early August to avoid the container shortages and space constraints that typically emerge in September.

What packaging and documentation preparations help?

Preparing shipping documentation while products are in production eliminates the 2-4 day documentation delay that often occurs between production completion and actual shipment. Having commercial invoices, packing lists, certificates of origin, and other required documents ready before goods complete production can advance shipping by up to 5 days. This seemingly small efficiency becomes critical when facing tight delivery deadlines.

Conclusion

Mitigating peak season fabric mask production delays requires a comprehensive approach combining advanced planning, strategic inventory management, manufacturing flexibility, strong supplier relationships, and logistics preparedness. The most successful strategies begin months before peak season and create multiple layers of protection against both predictable bottlenecks and unexpected disruptions. By implementing these approaches systematically, businesses can maintain delivery schedules, preserve customer relationships, and capture peak season revenue opportunities that might otherwise be lost to production delays.

Remember that peak season planning isn't just about preventing delays—it's about creating competitive advantage through reliability when others are struggling with disruptions. The investment in robust peak season strategies pays dividends through maintained customer trust and captured market opportunities.

Ready to develop a comprehensive peak season strategy for your fabric mask production? Contact our Business Director, Elaine, at elaine@fumaoclothing.com to discuss our peak season preparedness programs and how we can help ensure your production remains on schedule despite seasonal challenges. We'll share specific strategies tailored to your product mix and market requirements.